Plate loading and unloading device

A loading and unloading device and sheet material technology, applied in the direction of transportation and packaging, conveyor objects, support frames, etc., to achieve the effects of improving processing efficiency, personal safety protection, and improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

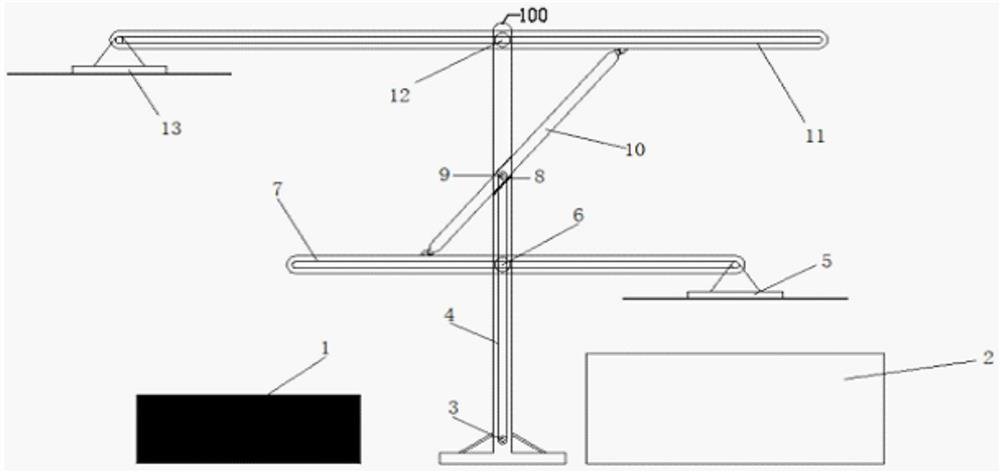

[0026] like figure 1 As shown, it is a structural schematic view of a sheet handling device according to a preferred embodiment of the present invention, and the sheet handling device 100 of the present embodiment includes a first slide rail 7 and a second sliding rail 11, the first slippery The rail 7 and the second sliding rail 11 are coupled by a linkage connection, and the first slide rail 7 and the second slide rail 11 are respectively provided with a first electromagnetic suction cup 5 and a second electromagnetic suction cup 13, respectively. The loading and unloading and transportation of the sheet is performed by fitting the first electromagnetic suction cup 5 and the second electromagnetic chuck 13.

[0027] The left and right sides of the sheet handling device 100 are respectively disposed as sheets 1 and machine 2, and the lower end of the sheet handling device 100 is provided with a motor 3, and the motor 3 is fixedly connected to the sheet loading and unloading devic...

Embodiment 2

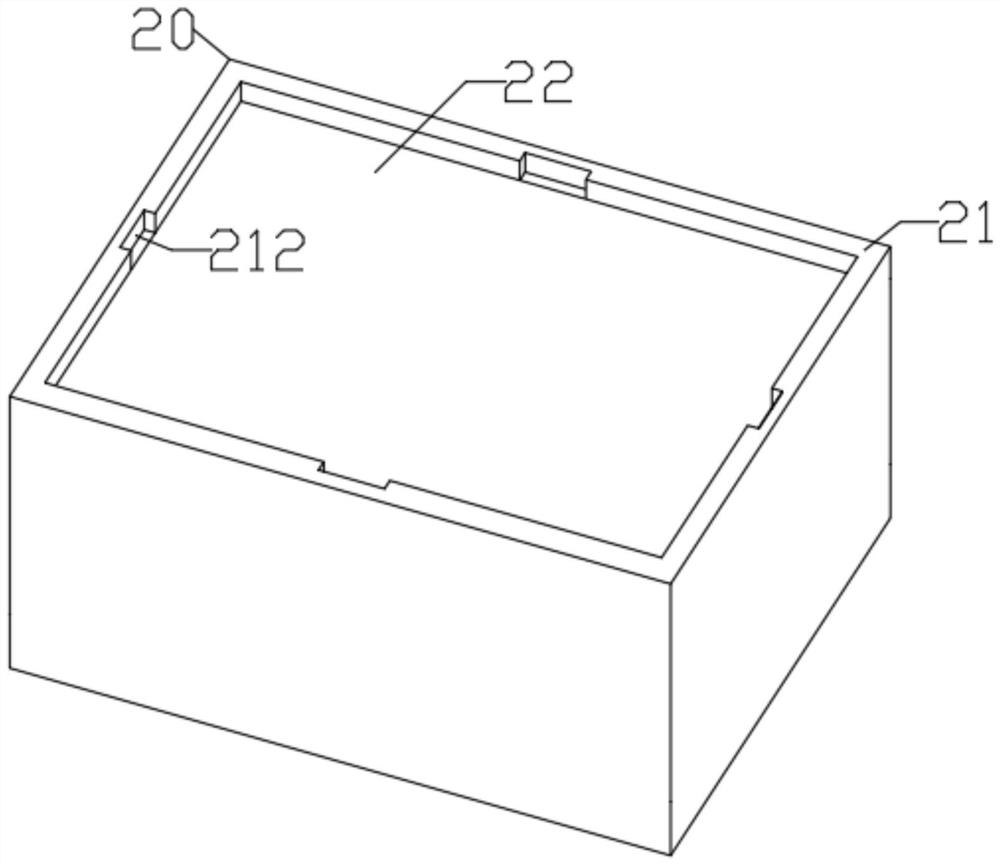

[0033] like Figure 2 ~ 5 As shown, it is a schematic structural diagram of a sheet handling device according to another preferred embodiment of the present invention, and the sheet handling device 100 of the present embodiment is provided on the basis of Example 1, and the sheet placing box 20 is provided. The sheet 1 is placed and the height adjustment allows the height of the sheet 1 to always fits the sheet loading and unloading device 100 for the loading and unloading of the sheet 1.

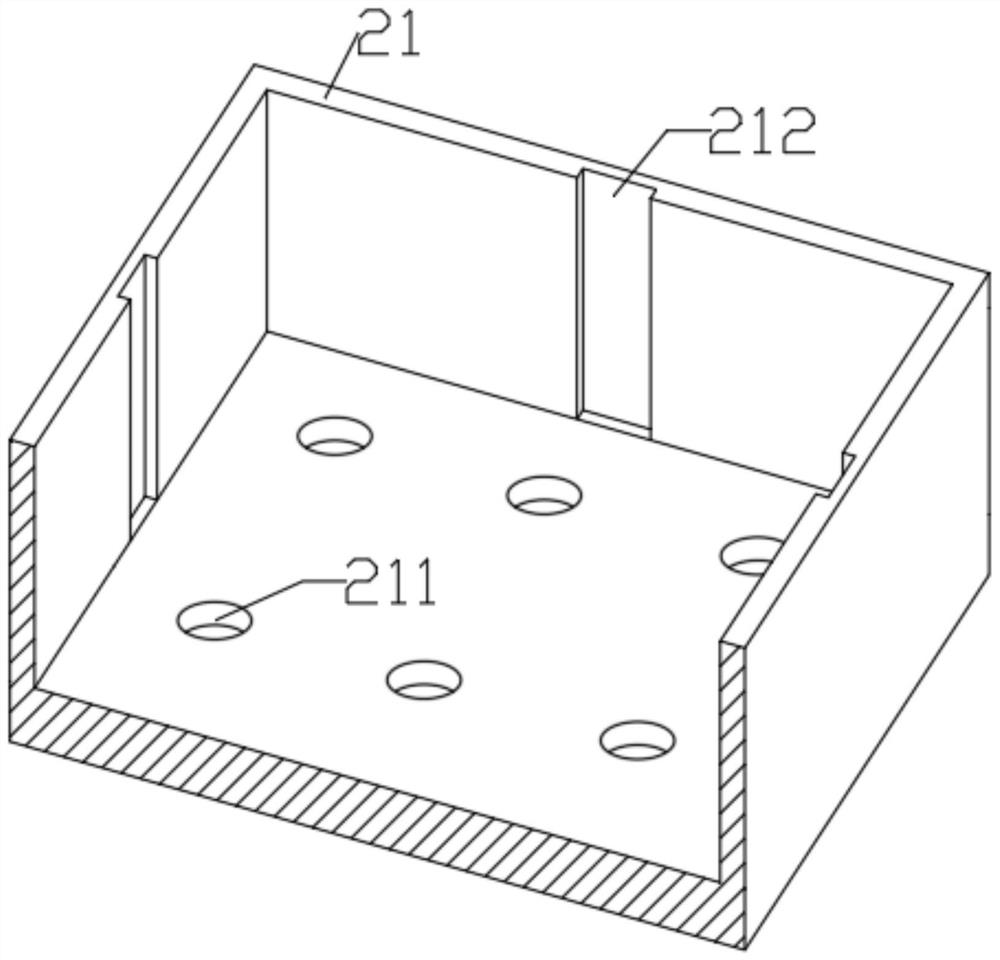

[0034] The sheet placing tank 20 includes a casing 21, a sheet plate 22, and a tough spring 23, and a spring mounting groove 211 is provided on the bottom plate of the casing 21, which is used to mount toughness. The spring 23 is provided with a sliding positioning groove 212 on the four-week inner wall of the casing 21, which is used to connect the mounting sheet placement plate 22.

[0035] A sliding positioning block 221 is provided on the four-week outer wall of the sheet plate 22, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com