Rust removal device and rust removal process for steel structure

A steel structure and steel bar technology, applied in the direction of grinding drive devices, manufacturing tools, grinding workpiece supports, etc., can solve the problems of high utilization rate of derusting equipment, high labor intensity of staff, low derusting efficiency, etc., to achieve increased Slip stability, reduce labor intensity, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following is attached Figure 1-11 The application is described in further detail.

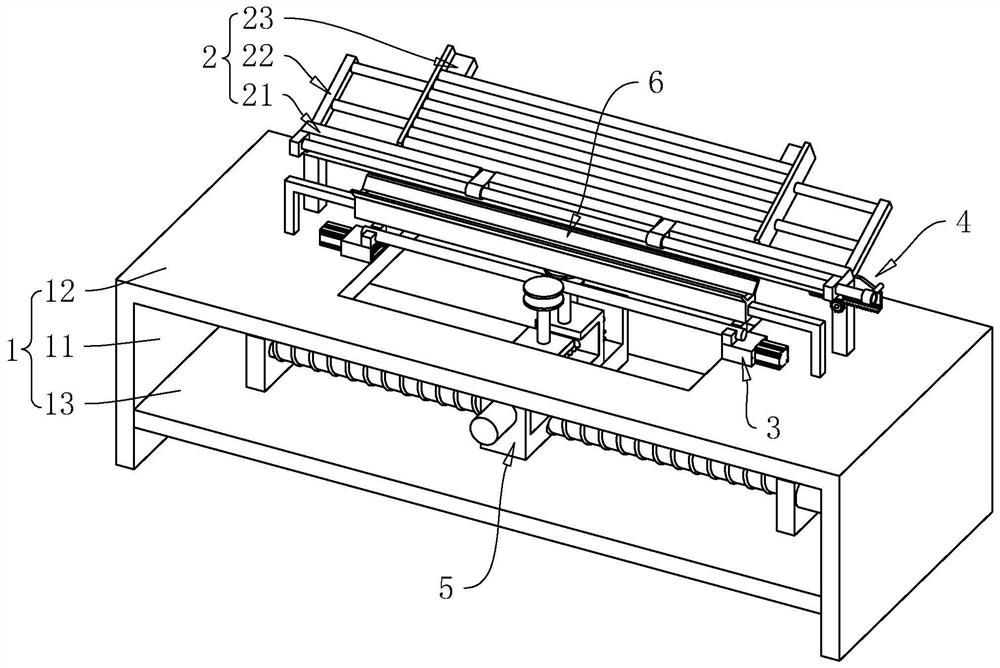

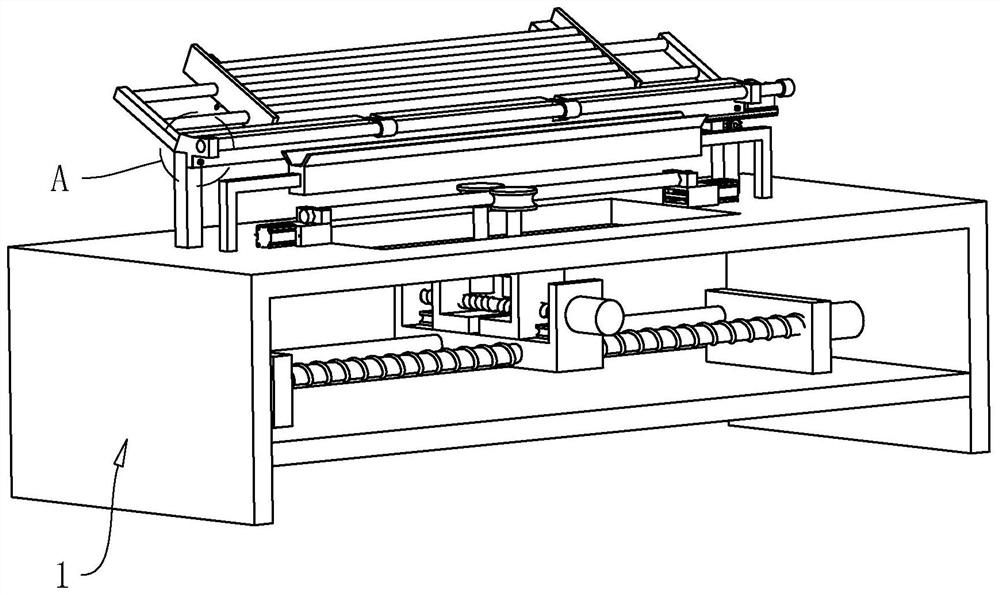

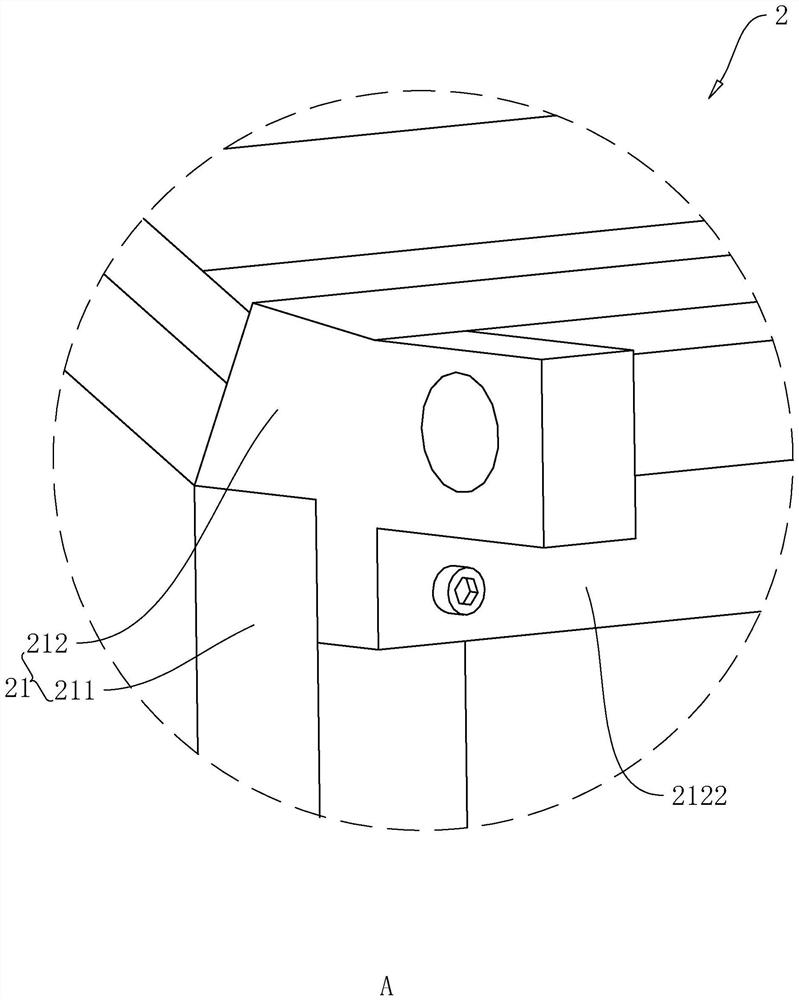

[0066] The application provides a steel structure derusting device, referring to figure 1 The steel structure derusting device includes a workbench 1, which is sequentially provided with a discharge mechanism 2 for placing steel bars or steel pipes, a clamping mechanism 3 for clamping steel bars or steel pipes, and a mechanism for placing steel bars or steel pipes on the discharge mechanism 2. The steel pipe is transported to the clamping mechanism 3 and the feeding mechanism 4, which is used to ensure that the steel bar or steel pipe accurately falls into the clamping mechanism 3, the material guide mechanism 6, and the rust removal mechanism 5 for the steel bar or steel pipe.

[0067] refer to figure 1 , the workbench 1 includes two support plates 11 and a mounting plate 12, the two support plates 11 are vertically arranged, the mounting plate 12 is horizontally arranged, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com