An inner hole boring cutter adjustment seat

A technology for adjusting seats and boring tools, which is applied in the direction of tool holders, etc., which can solve the problems of inconvenient processing and installation, easy retreat of the tool seat, and inconvenient adjustment process, and achieve the effects of easy control, high efficiency, and elimination of backlash gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

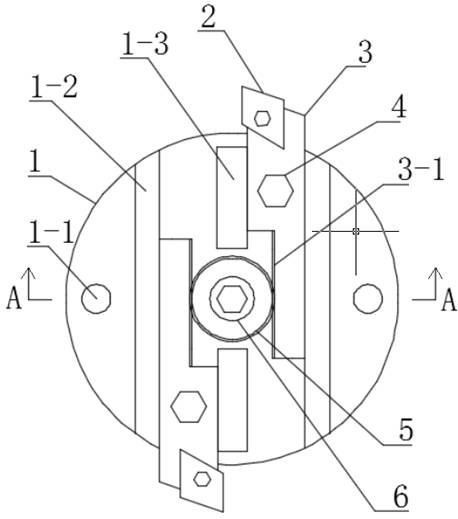

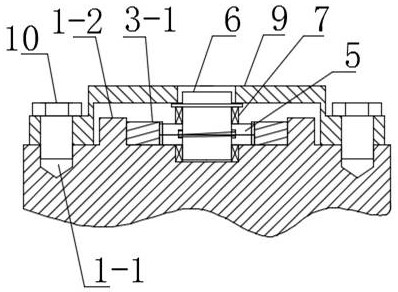

[0027] Example 1: Combining Figure 1 to Figure 3 As shown, an inner hole boring tool adjustment seat, two tool seats 3 are installed symmetrically at the center of the end face of the tool handle 1, and the outer end of the tool seat 3 fixes the tool 2.

[0028] The side slide bars 1-2 and the middle slide bars 1-3 are symmetrically arranged in pairs. The two middle slide bars 1-3 are on the same straight line passing through the shaft center of the end face of the knife handle 1. The two side slide bars 1-2 are separated on both sides of the middle slide bar 1-3, and the two knife holders 3 are slidably installed between the corresponding side slide bar 1-2 and the middle slide bar 1-3. A dovetail groove sliding connection is selected between the side slide bar 1-2 and the knife seat 3, which can prevent the knife seat 3 from jumping in the axial direction. The knife seat 3 is provided with an elongated hole, and the elongated hole is used to ensure that the knife seat 3 c...

Embodiment 2

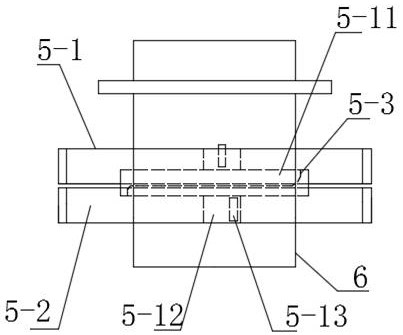

[0033] Embodiment two: combine figure 1 , figure 2 and Figure 4 As shown, the difference between the second embodiment and the first embodiment is that the fastening method of the tool holder 3 is different;

[0034]The middle slide bar 1-3 is made up of two oblique blocks 1-4. Set bolt 1-5 is installed in the threaded hole 1-1 on the inclined block 1-4, and set bolt 1-5 is perpendicular to the slope of inclined block 1-4. One side of the knife seat 3 close to the middle sliding bar 1-3 is provided with a sinking groove, and the tapered block 3-2 is embedded in the sinking groove on one side of the knife seat 3 and is fixedly connected by a fastening screw 8 . The tapered block 3-2 is located between the two inclined blocks 1-4, the inner end of the positioning bolt 1-5 faces the tapered block 3-2 and the positioning bolt 1-5 is perpendicular to the slope of the tapered block 3-2.

[0035] Through the two inclined and opposite positioning bolts 1-5, one is convenient to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com