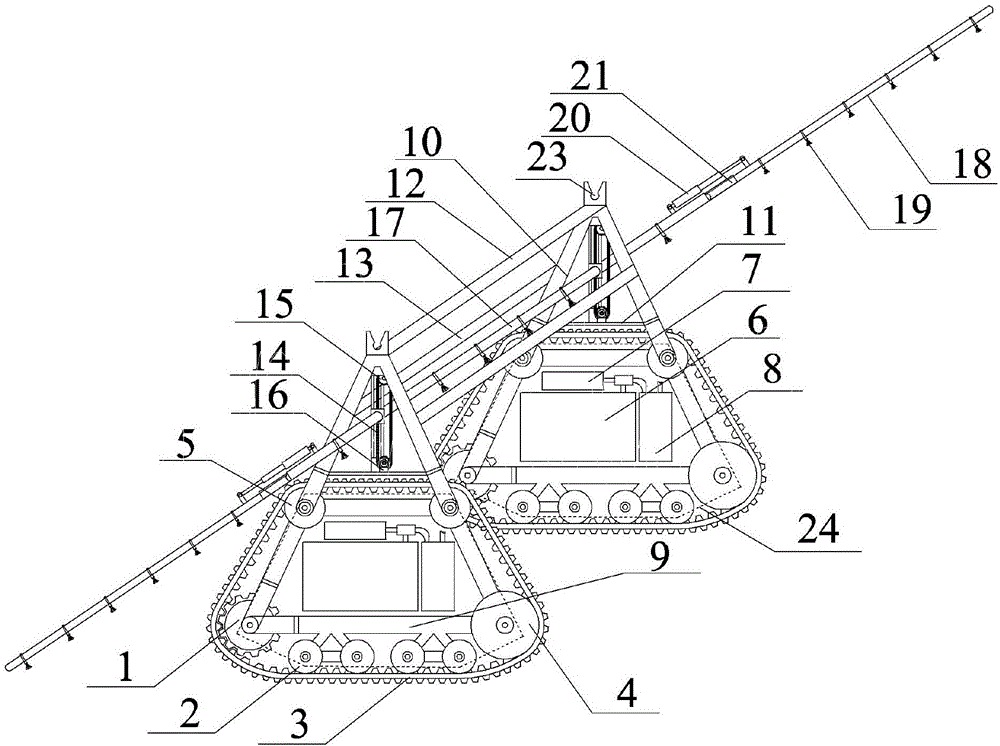

High-ground-clearance unmanned intelligent caterpillar sprayer and control method

An unmanned, sprayer technology, applied in tracked vehicles, non-electric variable control, control/regulation systems, etc., can solve the problems of poor scale effect, high labor intensity, low efficiency, etc., to save space and weight, improve Operating environment, the effect of reducing own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The working process of the inventive high-ground-gap unmanned intelligent crawler sprayer will be described in detail below in conjunction with the schematic diagram.

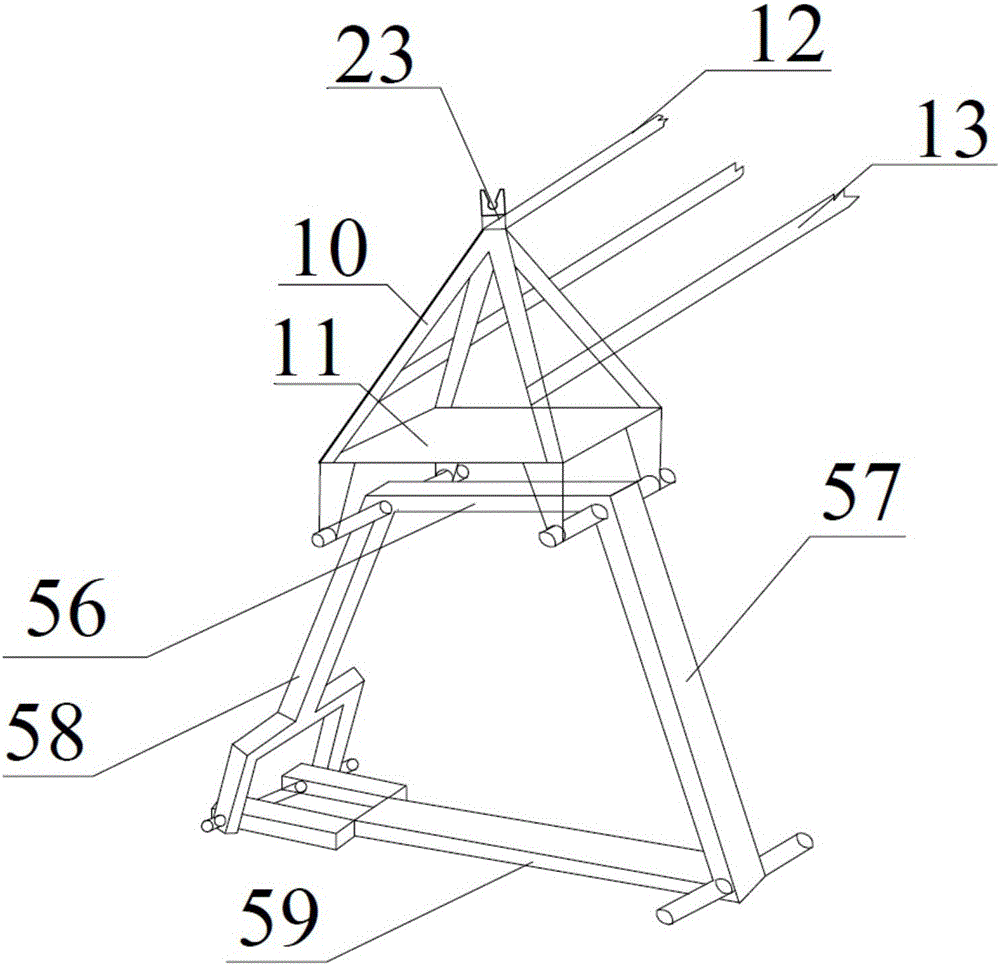

[0037] A high-gap unmanned intelligent crawler sprayer, including a sprayer walking device, a sprayer lifting mechanism, a spraying mechanism, and a control device; the sprayer walking device is composed of two crawler-type walking mechanisms driven by hub motors, The crawler-type traveling mechanisms on both sides are connected by fixed rods, and the top of the crawler-type traveling mechanisms on both sides is equipped with a sprayer lifting mechanism. The spraying mechanism includes a mixing device and a spray rod device; each crawler-type traveling mechanism is equipped with There is a trapezoidal bracket assembly; the mixing device and the control device are placed inside the trapezoidal bracket assembly on both sides, the spray rod device is set on the lifting mechanism of the sprayer and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com