High-precision full-dry ultrasonic bone densitometer and measurement method

A bone densitometer, all-dry technology, used in diagnostic recording/measurement, ultrasonic/sonic/infrasound equipment control, ultrasonic/sonic/infrasonic diagnosis, etc. problems such as stability and temperature uncertainty, to achieve the effect of eliminating width differences, ensuring consistency, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

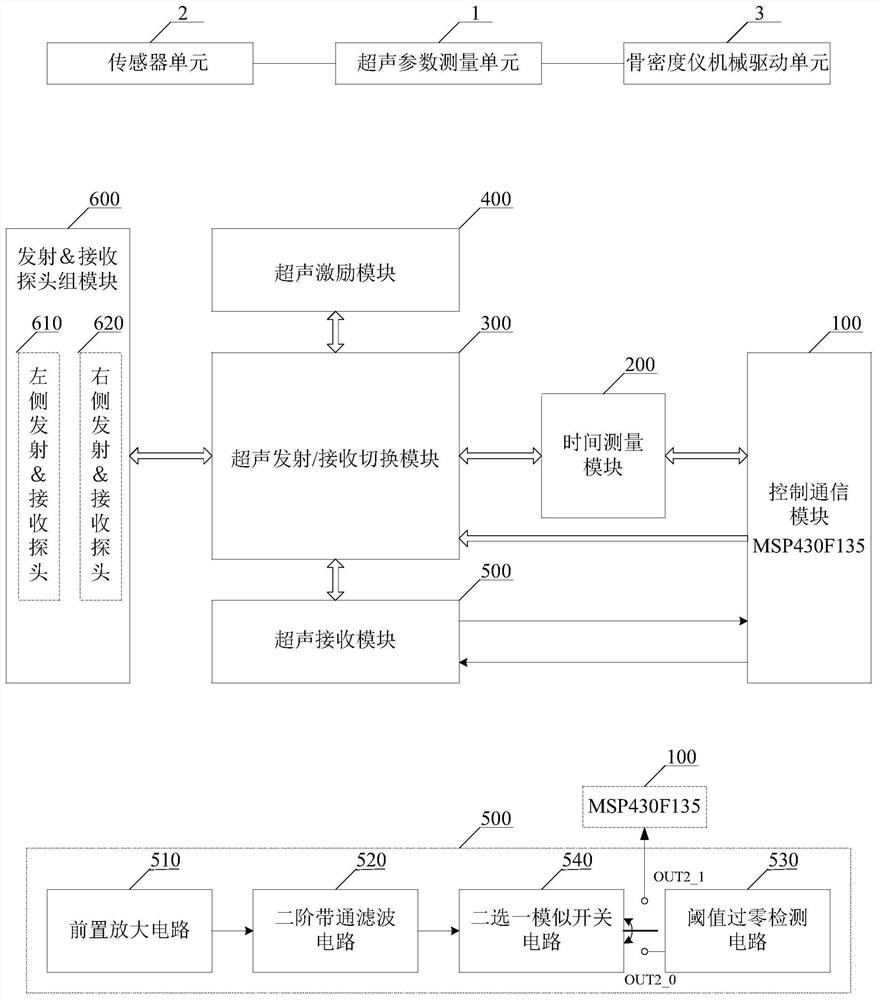

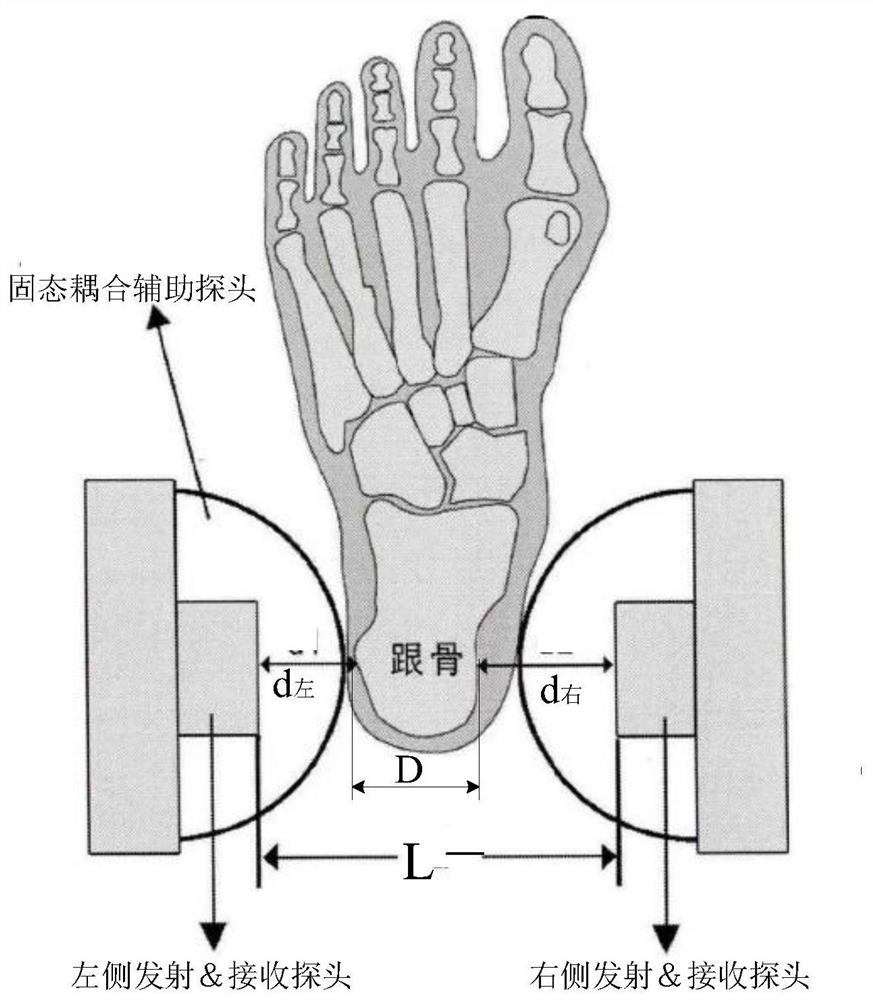

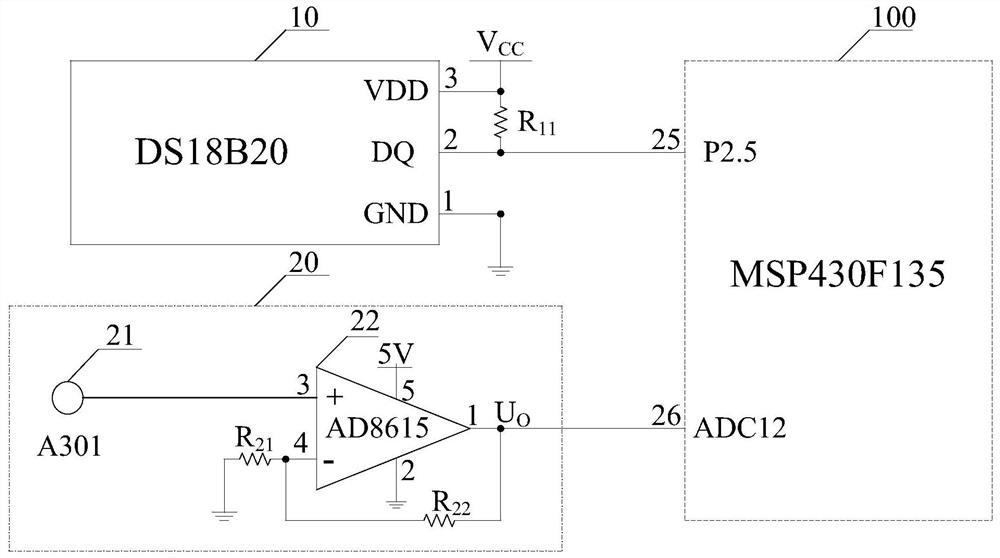

[0076] Such as figure 1 , figure 2 As shown, the high-precision full-dry ultrasonic bone densitometer is composed of an ultrasonic parameter measurement unit 1, a sensor unit 2, and a mechanical drive unit 3 of the bone densitometer. The ultrasonic parameter measurement unit 1 is connected to the sensor unit 2 and the mechanical drive unit 3 of the bone densitometer. Ultrasonic parameter measurement unit 1 comprises control communication module 100, time measurement module 200, ultrasonic emission / reception switching module 300, ultrasonic excitation module 400, ultrasonic reception module 500, emission & reception probe group module 600, control communication module 100 and time measurement The module 200, the ultrasonic transmission / reception switching module 300, and the ultrasonic receiving module 500 are connected, and the ultrasonic transmission / reception switching module 300 is connected with the time measurement module 200, the ultrasonic excitation module 400, the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com