Titanium alloy head and its preparation method and application

A technology of titanium alloy and head, applied in the field of titanium alloy head and its preparation, can solve the problems of affecting the service life of the pressure-resistant spherical shell, weak mechanical properties, and lack of metal flow lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

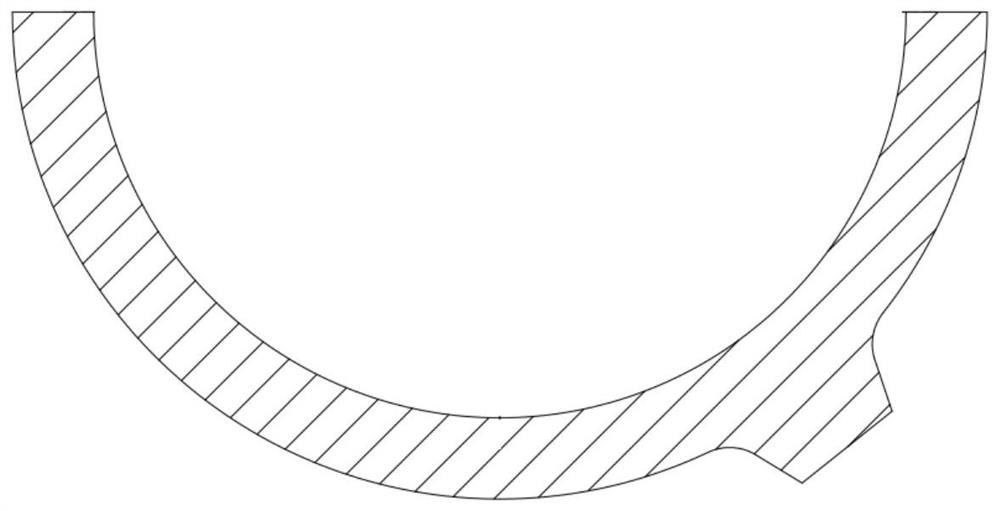

[0037] One embodiment of the present invention provides a method for preparing a titanium alloy head, including the following steps S10-S30.

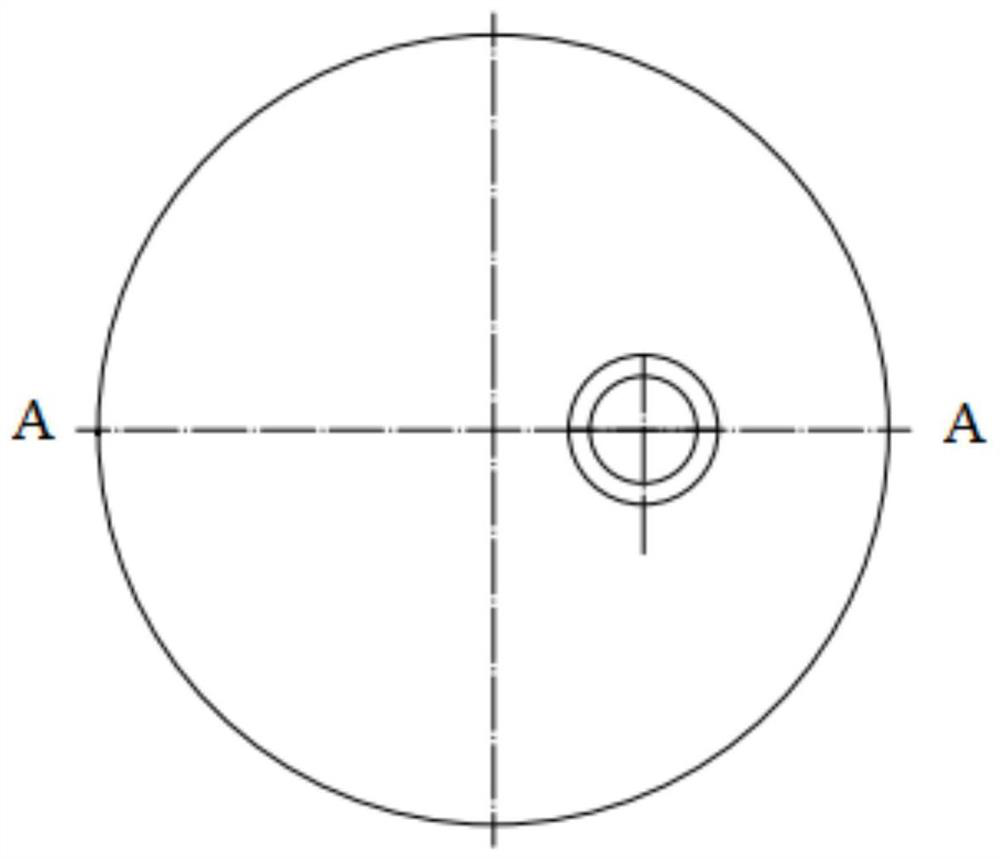

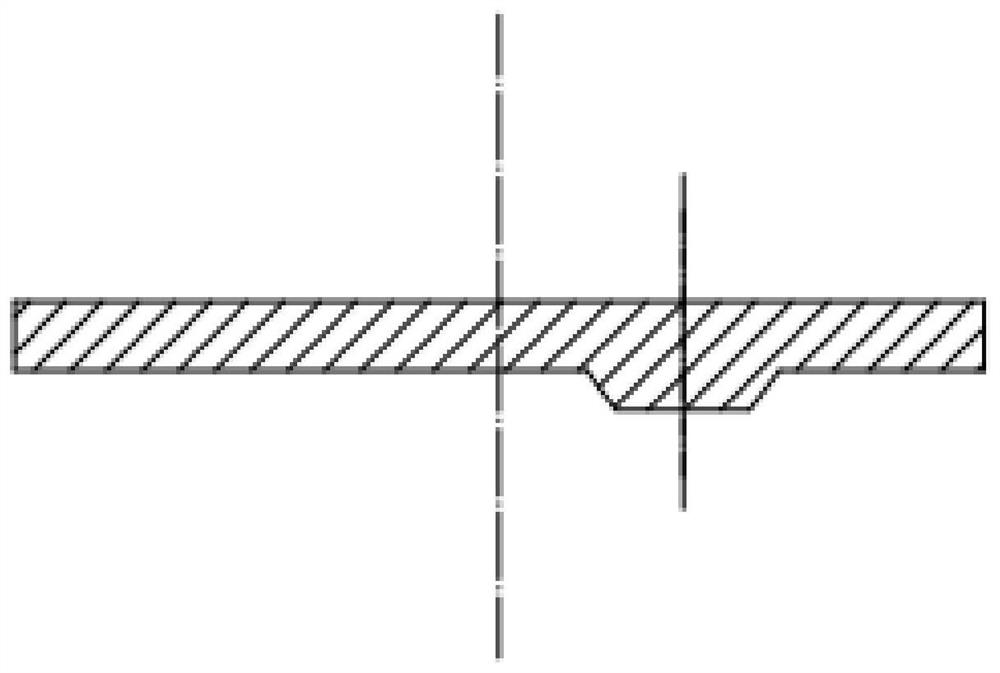

[0038] Step S10 , providing a titanium alloy slab, the titanium alloy slab includes a main body slab and a bump provided on the bottom of the main body slab.

[0039] Step S20, providing a stamping die, the stamping die includes an upper die and a lower die, the upper die has a hemispherical molding surface, the lower die has a first groove for accommodating the main body slab and a second groove for accommodating the bump, the second The groove is arranged on the bottom wall of the first groove and communicates with the first groove, and the molding surface of the upper mold cooperates with the first groove and the second groove of the lower mold to form a molding cavity.

[0040] Step S30, heating the titanium alloy slab to T β -20°C, then placed in the molding cavity of the die for n 1 Stamping to get the titanium alloy head; n 1 ...

Embodiment 1

[0080] (1) Titanium alloy head slab tooling mold design: According to the actual required titanium alloy head size, the relative position of the connection structure between the main body and accessories in the titanium alloy head is obtained through simulation, and the design drawing of the titanium alloy slab is obtained. Then prepare the head slab tooling mold according to the design drawing and reserve the machining allowance.

[0081] Specifically, the head slab tooling mold includes a main body conical cavity and a conical convex cavity arranged at the bottom of the main cavity, and the main cavity and the convex cavity are connected. The diameter of the main body cavity is 1700mm, the diameter of the conical convex cavity is 160mm, and the center point of the conical convex cavity is 130mm away from the center point of the main cavity.

[0082] (2) Preparation of titanium alloy slab:

[0083] The alloy ingot includes the following components by weight percentage: 2% to...

Embodiment 2

[0090] Example 2 is basically the same as Example 1, except that in step (3), the first groove of the lower mold is heated to 750°C, and the second groove of the lower mold is locally heated to 830°C.

[0091] Other processing steps and conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com