An inflatable metal stamping die for auto parts

A metal stamping and spare parts technology, applied in the field of inflatable metal stamping dies for auto parts, can solve problems such as deviation, low detection efficiency, time-consuming and laborious, and problems with the appearance of stamped products, and achieve the effect that it is not easy to fall off directly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

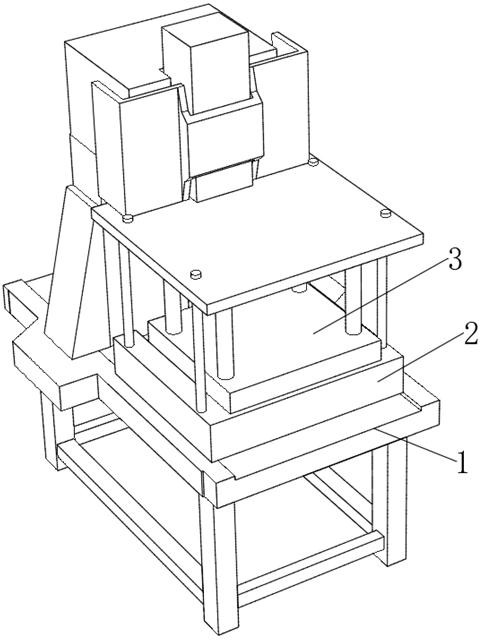

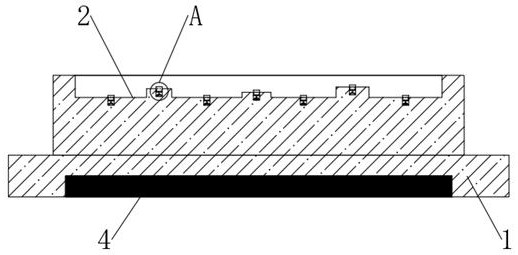

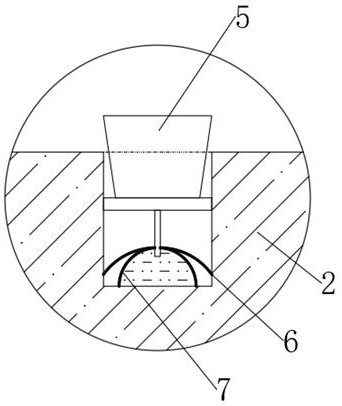

[0042] see Figure 1-4 , an inflatable metal stamping die for auto parts, comprising a press table 1, a fixed mold 2 and a movable mold 3 are installed on the upper end of the press table 1, and the fixed mold 2 is located at the lower side of the movable mold 3, and the fixed mold 2 is set There are a plurality of detection slots, and a matching detection block 5 is arranged in the detection slot. The detection block 5 includes a detection end 51, an extension end 52 and a plurality of support bars 53, and the extension end 52 and the support bars 53 are fixedly connected to the detection end 51. The lower end, and the extension end 52 is located at the center, the support bars 53 are distributed in a circular array around the extension end 52, the outer air film 6 is fixedly connected on the bottom wall of the detection groove, and the detection block 5 penetrates the outer air film 6 and extends to its inner side, the outer Marking powder 8 is distributed on the gas film 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com