Inclined micro-spraying cold plate

A tilting, cold plate technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of spray heat exchange effect not reaching the best, heat exchange surface coverage rate is not high, and achieve efficient heat dissipation and high coverage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

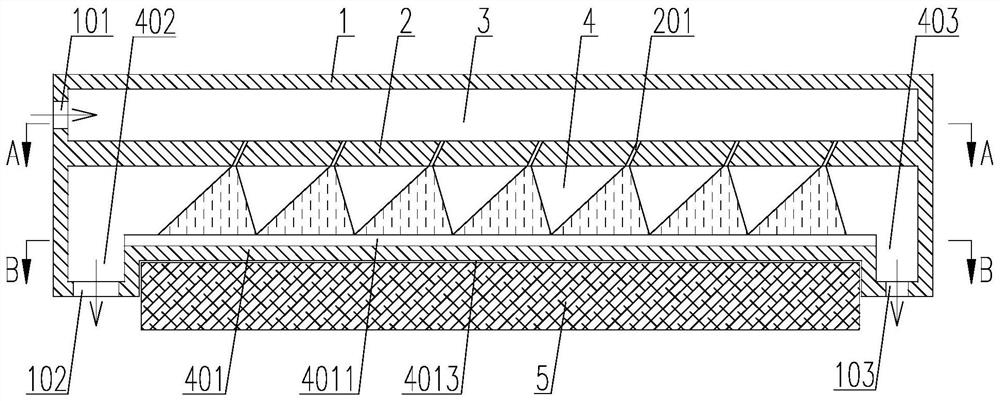

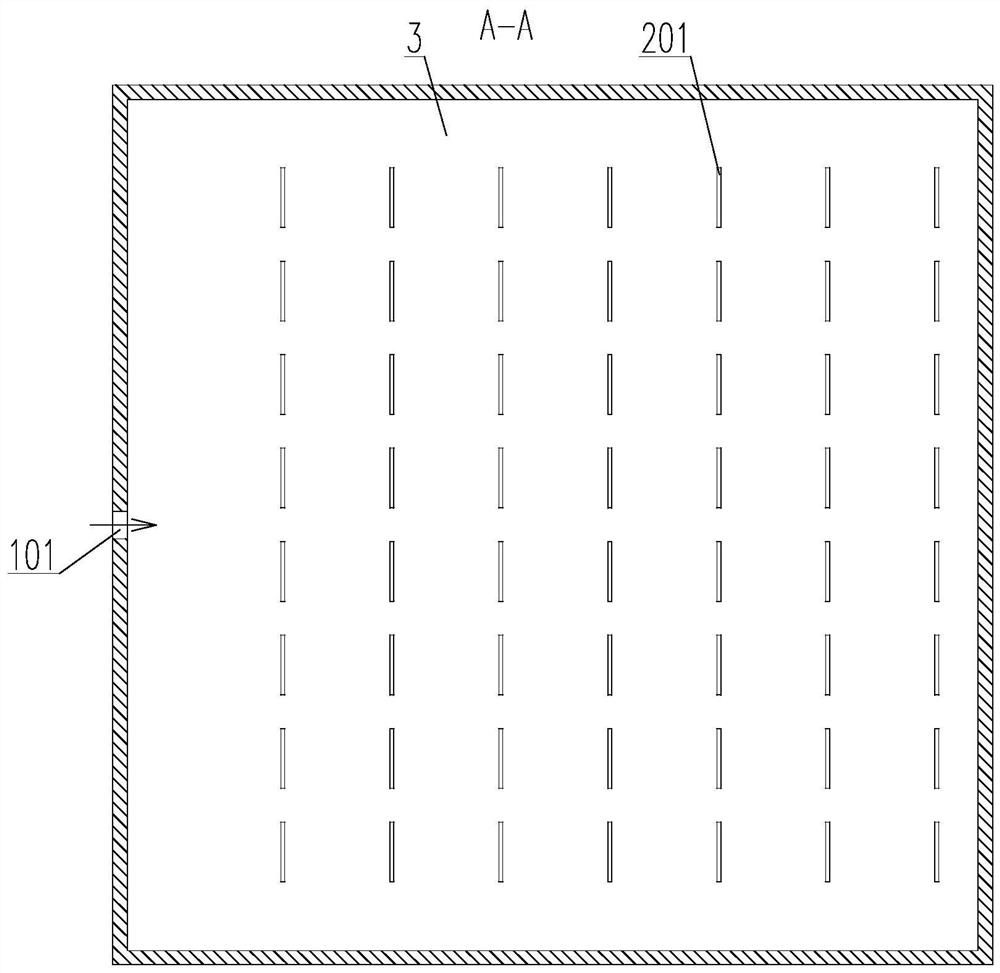

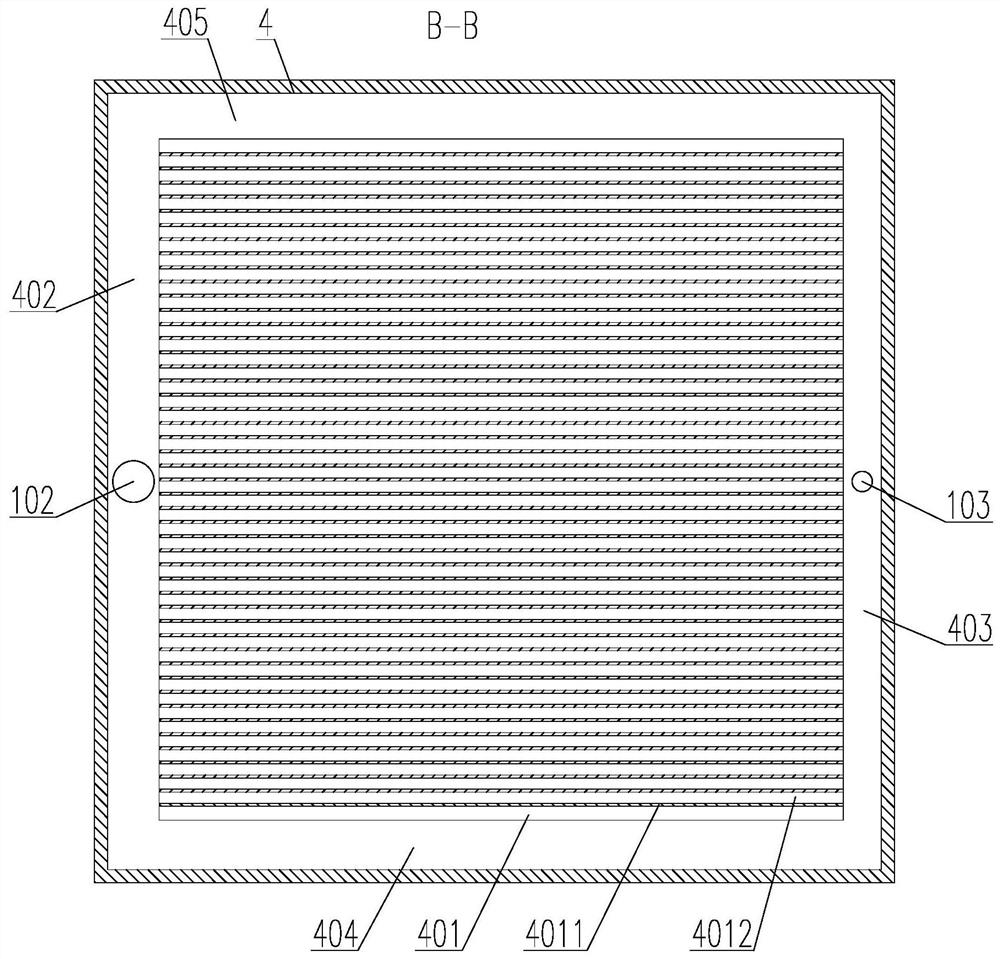

[0034] Such as Figure 1-3 As shown, a kind of inclined type micro-spray cold plate includes a cold plate body 1, which has an inner cavity in the cold plate body 1, and a partition 3 is fixed in the inner cavity, and the partition 3 separates the inner cavity into The upper static pressure chamber 3 and the lower spray chamber 4;

[0035] A heat exchange platform 401 protrudes upwards from the middle part of the bottom of the spray chamber 4, and the partition plate 3 has a spray hole group, and the spray hole group includes a number of flat spray holes 201 penetrating through the partition plate 3. The cross-section of the beam of the nozzle hole 201 is square, and several flat nozzle holes 201 are distributed on the partition plate 3 in an array. On the upper surface of the heat platform 401, a liquid discharge channel is formed between the outer surface of the heat exchange platform 401 and the inner peripheral surface of the spray chamber 4, and the outer wall of the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com