Solder joint failure parameter determination method, device, electronic device and storage medium

A technology of failure parameters and determination methods, applied in design optimization/simulation, electrical digital data processing, special data processing applications, etc., can solve problems affecting analysis accuracy, solder joint failure, etc., to improve modeling efficiency and improve technical effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

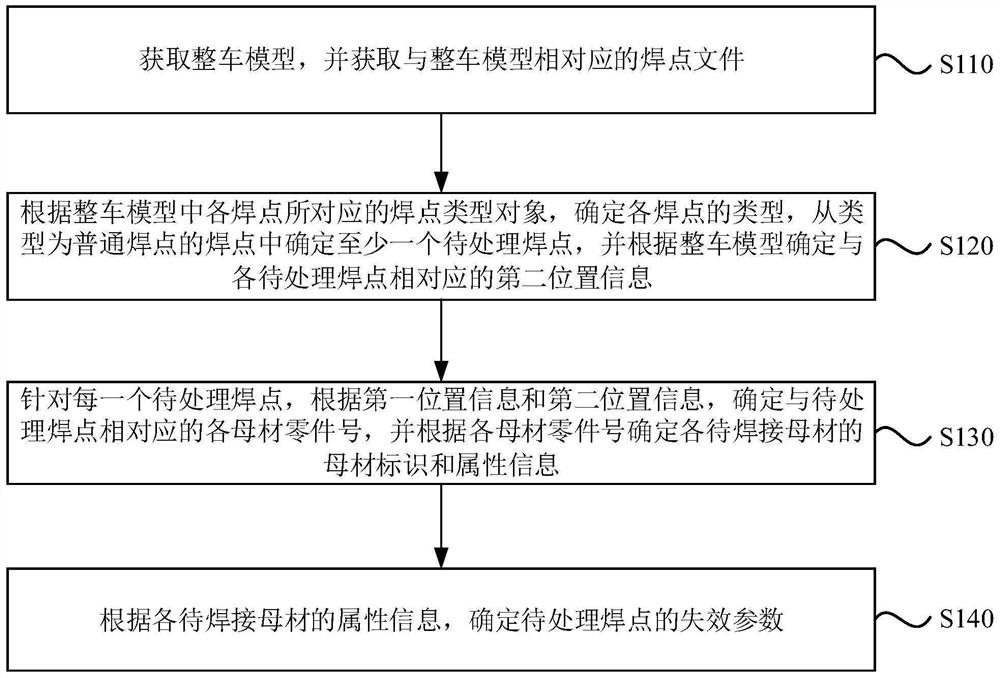

[0030] figure 1 This is a schematic flowchart of a method for determining the failure parameters of a solder joint provided by the first embodiment of the present invention. This embodiment can be applied to the situation where the failure parameters of the solder joints are determined by modeling, and the method can be determined by the failure parameters of the solder joints. The system can be implemented in the form of software and / or hardware, and the hardware can be an electronic device. Optionally, the electronic device can be a mobile terminal, a PC terminal, and the like.

[0031] like figure 1 Described, the method of this embodiment specifically includes the following steps:

[0032] S110. Acquire a vehicle model, and acquire a solder joint file corresponding to the vehicle model.

[0033] Wherein, the whole vehicle model may be a pre-established vehicle model whose welding point failure parameters are to be determined. The solder joint file may be a file construc...

Embodiment 2

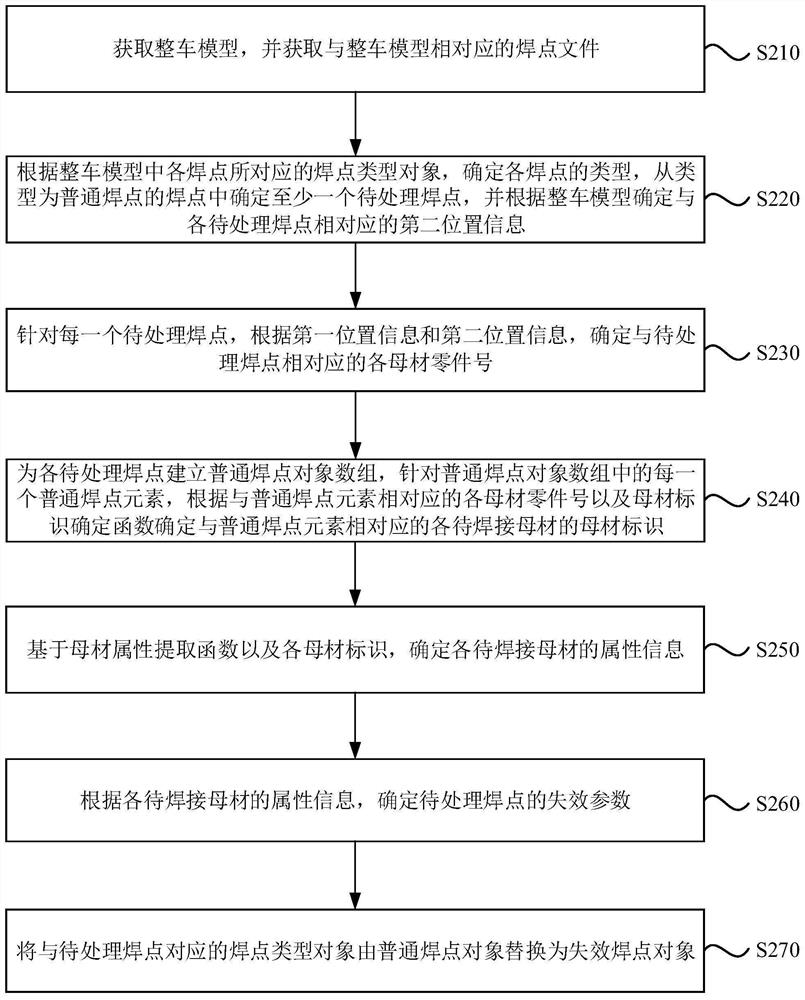

[0053] figure 2 This is a schematic flowchart of a method for determining failure parameters of solder joints provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment is directed to the conversion method of solder joint types and the parent metal identification of each parent metal to be welded. For the way of determining the attribute information, reference may be made to the technical solution of this embodiment. Wherein, the explanations of terms that are the same as or corresponding to the above embodiments are not repeated here.

[0054] like figure 2 Described, the method of this embodiment specifically includes the following steps:

[0055] S210. Acquire a vehicle model, and acquire a solder joint file corresponding to the vehicle model.

[0056] S220. Determine the type of each solder joint according to the solder joint type object corresponding to each solder joint in the vehicle model, determine...

Embodiment 3

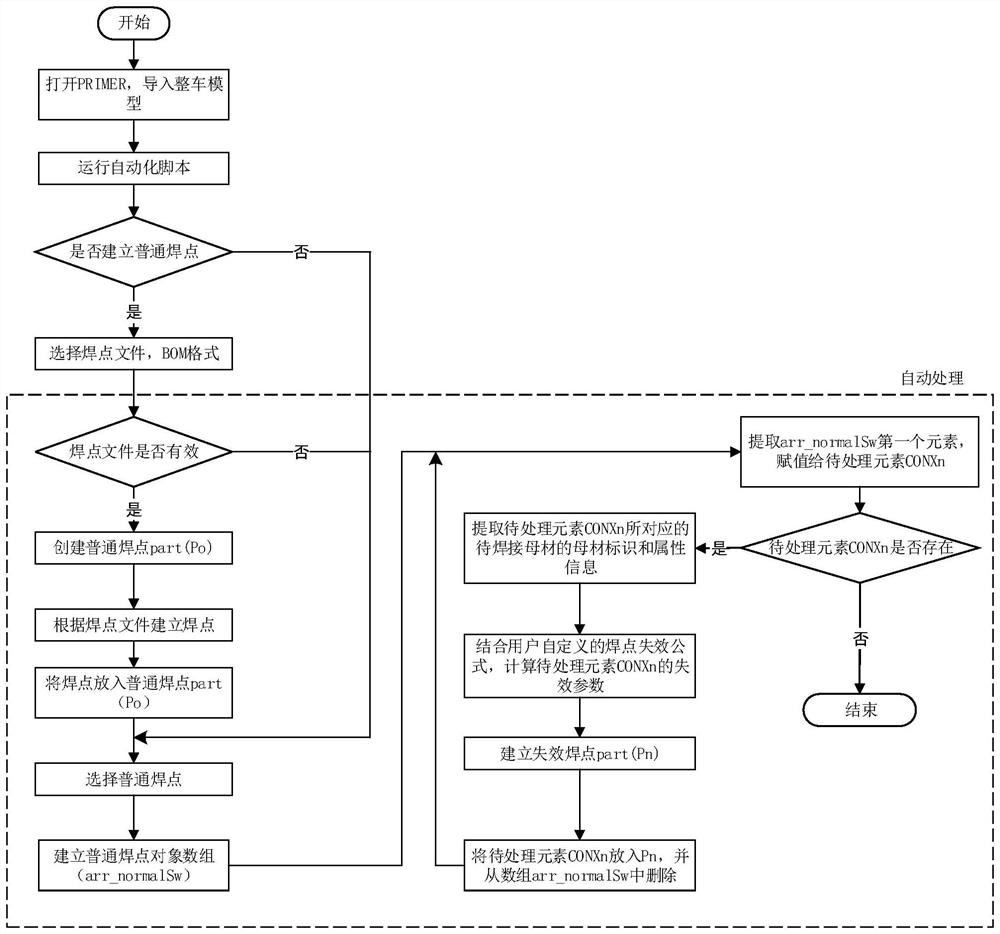

[0078] As an optional implementation of the above-mentioned embodiments, image 3This is a schematic flowchart of a method for determining a solder joint failure parameter provided by the third embodiment of the present invention. Wherein, the explanations of terms that are the same as or corresponding to the above embodiments are not repeated here.

[0079] like image 3 Described, the method of this embodiment specifically includes the following steps:

[0080] The first step is to design and program in the PRIMER software based on the JavaScript programming language.

[0081] The second step is to open the PRIMER software and import the vehicle model.

[0082] Specifically, the vehicle model can be imported and opened through "Model-Read" in the PRIMER software.

[0083] The third step is to select and run the automation script.

[0084] Specifically, in the PRIMER software, the "JavaScript" interface is called up through "Tools-Script", and the automation script is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com