Boiler flue gas multi-point drainage mixing detection device

A boiler flue gas and detection device technology, which is applied in the direction of measuring devices, analyzing gas mixtures, sampling devices, etc., can solve the problems of endangering the safety of the unit, economic operation, poor reliability, wrong operation, etc., and achieve good promotion and application value, Avoid pipeline dust accumulation, easy to create the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

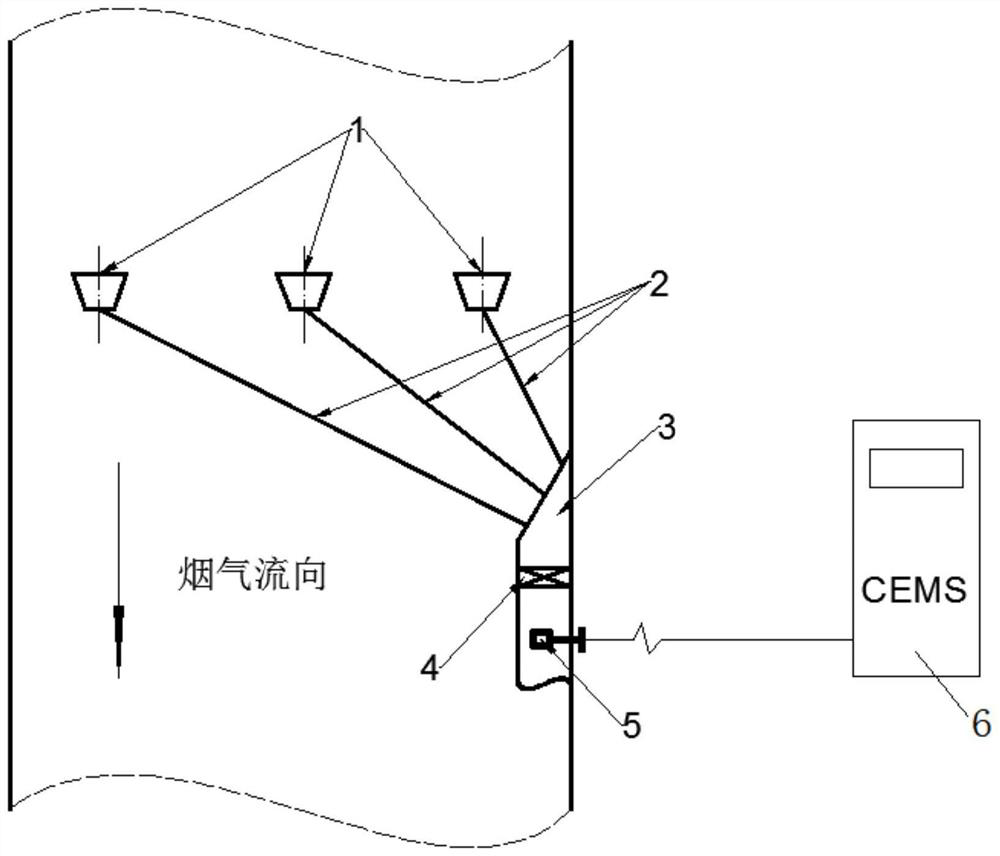

[0031] A boiler flue gas multi-point drainage mixing detection device of the present invention, such as figure 1 As shown, it includes a sampling system composed of a drainage chamber 1, a drainage tube 2, a manifold chamber 3 and a mixer 4, and a flue gas monitoring system composed of a CEMS probe 5 and a CEMS controller 6;

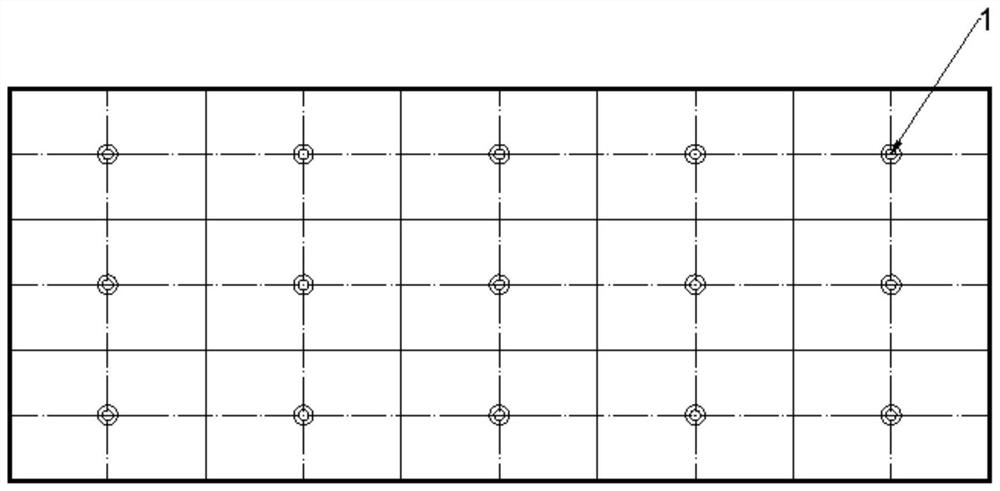

[0032] The drainage chamber 1 is a conical cylinder made of standard parts with different diameter joints, the central axis is consistent with the flow direction of the smoke, and the long diameter side section is the windward side, and the short diameter side is connected to the drainage pipe 2; several drainage chambers 1 adopt The grid method or the equal-area ring method is arranged on the flue section, such as figure 2 As shown, it is a schematic diagram of sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com