Waterproof roll laying clamp and construction method of waterproof roll at brick moulding bed part

A technology of waterproof roll material and brick tire mold, which is applied in the direction of infrastructure engineering, construction, protection devices, etc., can solve the problems of unsatisfactory waterproof effect of waterproof structures, and achieve good waterproof effect and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

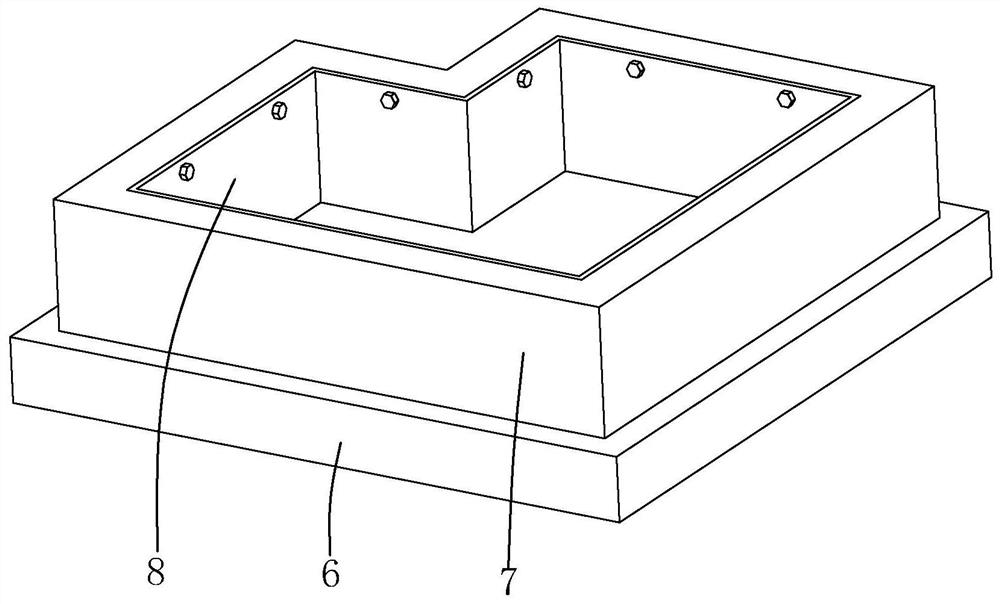

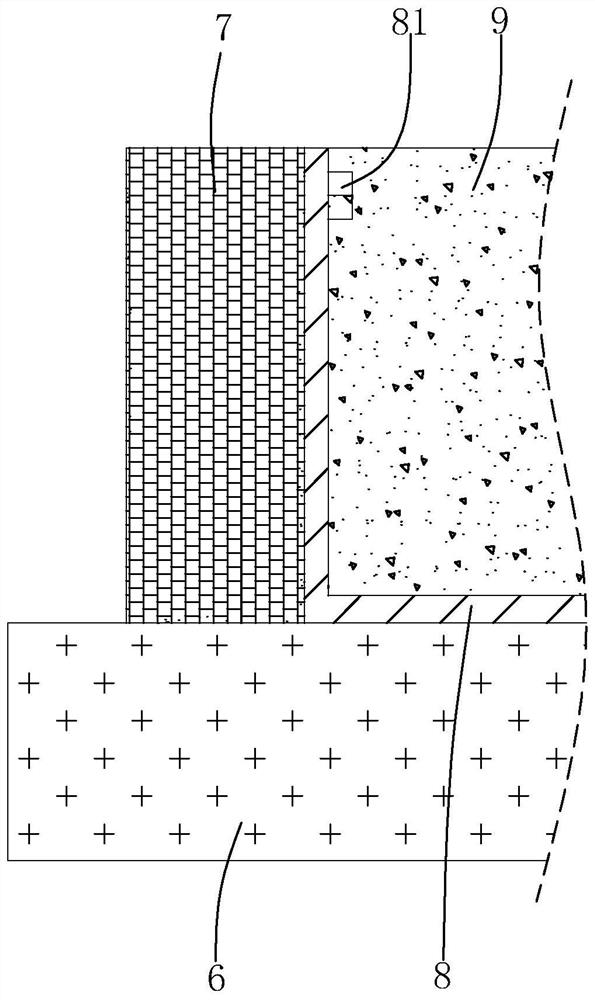

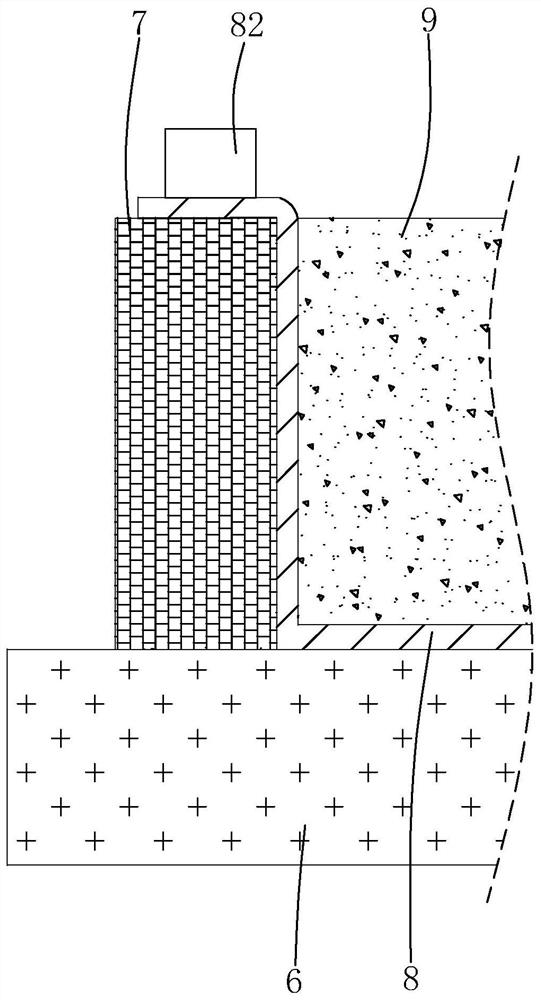

[0052] refer to Figure 4 and Figure 5 , the connecting piece 1 is a rod-shaped structure, and the two ends of the connecting piece 1 are fixedly connected with two clamping rods 2 respectively. The clamp in this embodiment can be formed by directly bending a steel bar.

[0053] The implementation principle of the embodiment of the present application is: in the process of underground waterproof structure construction, after the staff lays the waterproof coiled material 8 above the cushion layer 6 and within the brick tire mold 7, the staff can use multiple clamps to place the waterproof coiled material 8 The edge position of the top of the material 8 and the brick tire mold 7 are temporarily clamped and fixed. After the concrete is poured, the staff can remove the clamps, so that the fixing effect between the waterproof membrane 8 and the brick tire mold 7 is released, and the concrete In the process of condensation, if there is a slight volume shrinkage, it can drive the w...

Embodiment 2

[0055] refer to Figure 6 and Figure 7 , the connector 1 includes a middle part 11 and two adjustment parts 12, the middle part 11 includes a middle pipe 111 with a circular cross section, and a plurality of pipes arranged along the length direction of the middle pipe 111 are uniformly arranged at both ends of the middle pipe 111. Compression plate 112, the cross-section of the compression plate 112 is arc-shaped, and the curvature of the cross-section of the compression plate 112 is adapted to the curvature of the intermediate pipe 111, and a plurality of compression plates 112 at the same end of the intermediate pipe 111 surround The axes of the intermediate pipes 111 are evenly arranged, and the inner surface of the pressing plate 112 is fixedly connected with an elastic pad 1121 that is adapted to the curvature of the pressing plate 112 .

[0056] The middle pipe 111 is provided with two groups of pressing assemblies 3, and the two pressing assemblies 3 are located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com