Cigarette tipping paper containing novel sweetening agent and preparation method thereof

A technology of tipping paper and sweetener for cigarettes, applied in tobacco, papermaking, application, etc., can solve problems such as air pollution, public air pollution, harmful physical and mental health, etc., achieve moderate sweetness, enhance sweetness, enhance The effect of odor direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

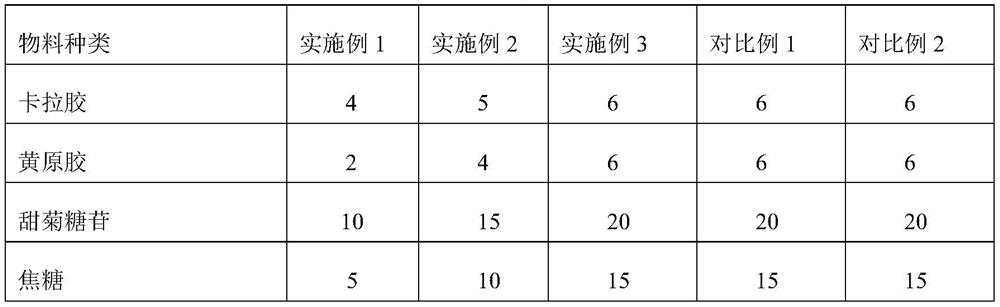

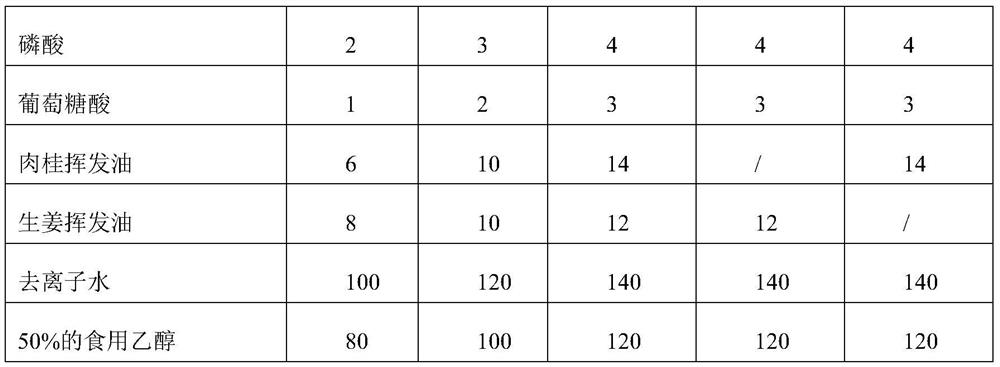

Embodiment 1

[0025] Concrete raw material is weighed by table 1, and step preparation step is as follows:

[0026] (1) Stir carrageenan and 1 / 2 deionized water at a temperature of 50°C and 800 rpm for 20 minutes, then add xanthan gum, and continue stirring for 20 minutes to obtain mixture A;

[0027] (2) Stir steviol glycoside, caramel and the remaining deionized water at 800 rpm for 15 minutes, then add phosphoric acid and gluconic acid and continue stirring for 20 minutes, and then mix with mixture A for 20 minutes to obtain mixture B;

[0028] (3) Stir cinnamon volatile oil, ginger volatile oil and edible ethanol at 800 rpm for 30 minutes, then mix and stir with mixture B for 40 minutes to obtain a sweetener sticky layer;

[0029] (4) Apply the prepared sweetener sticky layer on the base paper base material by using a gluing device, and dry it at a temperature of 95° C. to obtain it.

Embodiment 2

[0031] (1) Stir carrageenan and 1 / 2 deionized water at 60°C and 1200 rpm for 15 minutes, then add xanthan gum and continue stirring for 15 minutes to obtain mixture A;

[0032] (2) Stir steviol glycoside, caramel and the remaining deionized water at 1200 rpm for 10 minutes, then add phosphoric acid and gluconic acid and continue stirring for 15 minutes, and then mix with mixture A for 10 minutes to obtain mixture B;

[0033] (3) Stir cinnamon volatile oil, ginger volatile oil and edible ethanol at 1200 rpm for 20 minutes, then mix and stir with mixture B for 30 minutes to obtain a sweetener sticky layer;

[0034] (4) Apply the prepared sweetener sticky layer on the base paper base material by using a gluing device, and dry it at a temperature of 105° C. to obtain it.

Embodiment 3

[0036] (1) Stir carrageenan and 1 / 2 deionized water at 60°C and 1200 rpm for 20 minutes, then add xanthan gum, and continue stirring for 20 minutes to obtain mixture A;

[0037] (2) Stir steviol glycoside, caramel and the remaining deionized water at 1200 rpm for 15 minutes, then add phosphoric acid and gluconic acid to continue stirring for 20 minutes, and then mix with mixture A for 20 minutes to obtain mixture B;

[0038] (3) Stir cinnamon volatile oil, ginger volatile oil and edible ethanol at 1200 rpm for 30 minutes, then mix and stir with mixture B for 40 minutes to obtain a sweetener sticky layer;

[0039] (4) Apply the prepared sweetener adhesive layer on the base paper base material by using a gluing device, and dry it at a temperature of 100° C. to obtain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com