Method for preparing rigid polyurethane foam from epoxidized lignin polyol

A polyurethane rigid foam and lignin technology, which is applied in the field of epoxidized lignin polyols to prepare polyurethane rigid foam, can solve the problems of many side reactions and poor thermal stability, and achieve less side reactions, strong thermal stability, and high uniformity sex and regularity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

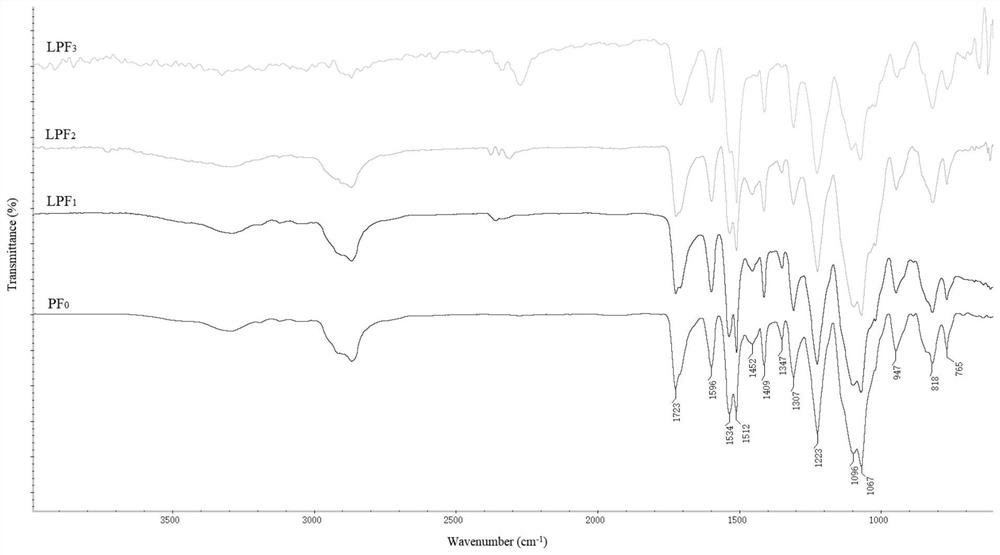

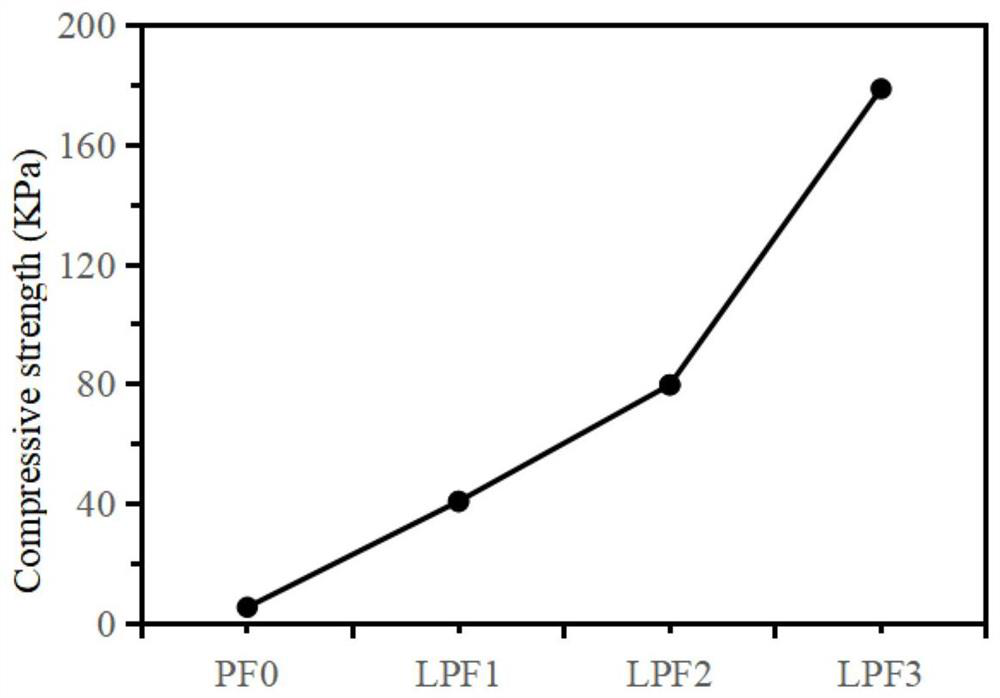

[0024] The preparation method of embodiment 1 polyurethane rigid foam

[0025] Add polyether polyol (PEG-400) into a plastic beaker, then add lignin polyol and stir evenly for 4 minutes, the molar ratio of the hydroxyl value of lignin polyol to polyether polyol is 2:8, and then add catalyst two Butyl tin dilaurate, foam stabilizer silicone oil AK-8805 and foaming agent water, mix well and then stir for 4 minutes, finally add a certain amount of isocyanate (polymeric MDI) according to the number of isocyanate (NCO / OH) is 1.05, and use electric stirring When the rotating speed reaches 2000r / min, stir rapidly for 40s to carry out free foaming to prepare lignin-based polyurethane rigid foam material.

[0026] The number of isocyanates is determined according to the total molar weight of isocyanate in isocyanates and the total hydroxyl value of lignin polyols and polyether polyols. The formula for calculating the number of isocyanates is as follows:

[0027] NCO / OH=M MDI ×W MDI ...

Embodiment 2

[0029] The preparation method of embodiment 2 polyurethane rigid foam

[0030] Add polyether polyol (PEG-400) into a plastic beaker, then add lignin polyol and stir evenly for 4 minutes, the molar ratio of the hydroxyl value of lignin polyol to polyether polyol is 3:7, and then add catalyst two Butyl tin dilaurate, foam stabilizer silicone oil AK-8805 and foaming agent water, mix well and then stir for 4 minutes, finally add a certain amount of isocyanate (polymeric MDI) according to the number of isocyanate (NCO / OH) is 1.05, and use electric stirring When the rotating speed reaches 2000r / min, stir rapidly for 40s to carry out free foaming to prepare lignin-based polyurethane rigid foam material.

[0031] The number of isocyanates is determined according to the total molar weight of isocyanate in isocyanates and the total hydroxyl value of lignin polyols and polyether polyols. The formula for calculating the number of isocyanates is as follows:

[0032] NCO / OH=M MDI ×W MDI ...

Embodiment 3

[0034] The preparation method of embodiment 3 polyurethane rigid foam

[0035] Add polyether polyol (PEG-400) into a plastic beaker, then add lignin polyol and stir evenly for 4 minutes, the molar ratio of the hydroxyl value of lignin polyol to polyether polyol is 4:6; then add catalyst two in sequence Butyl tin dilaurate, foam stabilizer silicone oil AK-8805 and foaming agent water, mix well and then stir for 4 minutes, finally add a certain amount of isocyanate (polymeric MDI) according to the number of isocyanate (NCO / OH) is 1.05, and use electric stirring When the rotating speed reaches 2000r / min, stir rapidly for 40s to carry out free foaming to prepare lignin-based polyurethane rigid foam material.

[0036] The number of isocyanates is determined according to the total molar weight of isocyanate in isocyanates and the total hydroxyl value of lignin polyols and polyether polyols. The formula for calculating the number of isocyanates is as follows:

[0037] NCO / OH=M MDI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com