Preparation method of high-sensitivity temperature-sensing reversible color-changing microcapsule

A technology of microcapsules and color-changing dyes, applied in the field of material science, can solve the problems of color change hysteresis, limit dye high sensitivity and fast response application and development, color hysteresis, etc., and achieve improved color hysteresis, good color performance, and color change response performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

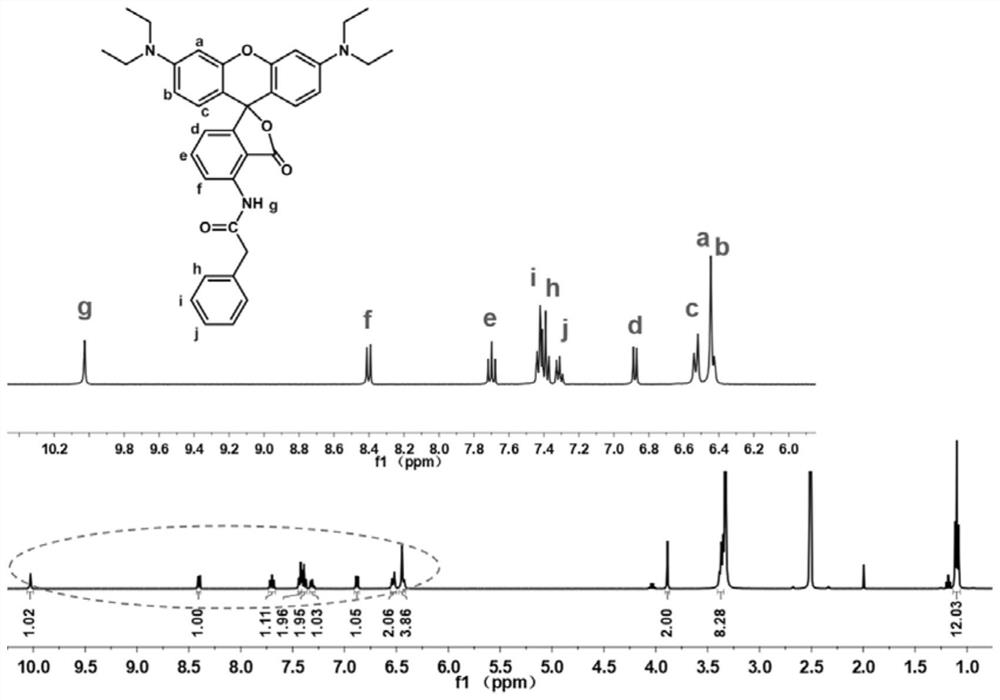

[0036] Preparation of No. 6 novel fluoran dye: 50mmol 3-(diethylamino)phenol and 25mmol 3-nitrophthalic anhydride were added to a three-necked flask containing 50mL chlorobenzene, and after completely dissolving, 25mmol trifluoromethane was added sulfonic acid. Then put the three-neck flask into a 135°C oil bath to preheat, and react under nitrogen reflux for 2 days. After the reaction is completed, cool to room temperature, and remove the solvent by rotary evaporation. Using dichloromethane (DCM) / methanol as eluent for column chromatography, a purple powder was obtained, the product ph-NO 2 .

[0037] 1 mmol ph-NO 2 , 20mg Pd / C, 4mL ethyl acetate (EtOAc), put into a three-necked flask. 1.5 mmol H 3 PO 2 and 4.5 mmol NaH 2 PO 2 ·H 2 O was homogeneously dissolved in 4 mL of H 2 After being placed in O, it was poured into the above-mentioned three-neck flask. Then the three-neck flask was put into an oil bath at 85°C for 5 hours, cooled to room temperature, and extract...

Embodiment 2

[0058] Embodiment 2 adopts No. 6 novel fluoran dye identical with embodiment 1.

[0059] Preparation of fuchsia two-component temperature-sensitive reversible color dye compound: No. 6 new fluorane dye (0.1g), 15g cetyl alcohol, magnetic stirring for 1 hour at 50°C, to obtain uniformly mixed fuchsia Two-component thermosensitive reversible color dye complex.

[0060] Preparation of fuchsia two-component temperature-sensitive reversible discoloration microcapsules: take 1.5 g of fuchsia two-component temperature-sensitive reversible discoloration dye complex and 0.75 g polymethyl methacrylate dissolved in 5 mL dichloromethane ( DCM), and then add an emulsifier aqueous solution (2%, 1.0 g gelatin mixed in 49 mL water), and stir at 5000 r / min for 20 min at room temperature to form an O / W emulsion. Pour the O / W emulsion into a beaker, and stir at a speed of 400 r / min for 8 hours at 35°C until the DCM is completely volatilized. After adding deionized water and standing still, dec...

Embodiment 3

[0068] Preparation of No. 2 novel fluoran dye: dissolve 3-diethylaminophenol (1.65g) and 3-nitrophthalic anhydride (2.89g) in toluene (25ml), put them into a three-necked flask, and put them in an oil bath at 110°C Pot reaction 4h, cooled to room temperature, extracted with a small amount of petroleum ether. The supernatant was removed to obtain a purple-red precipitate. Purify the precipitate by column chromatography using dichloromethane / methanol as the eluent to obtain a golden yellow powder, which is the product 4-diethylaminonitroketoacid.

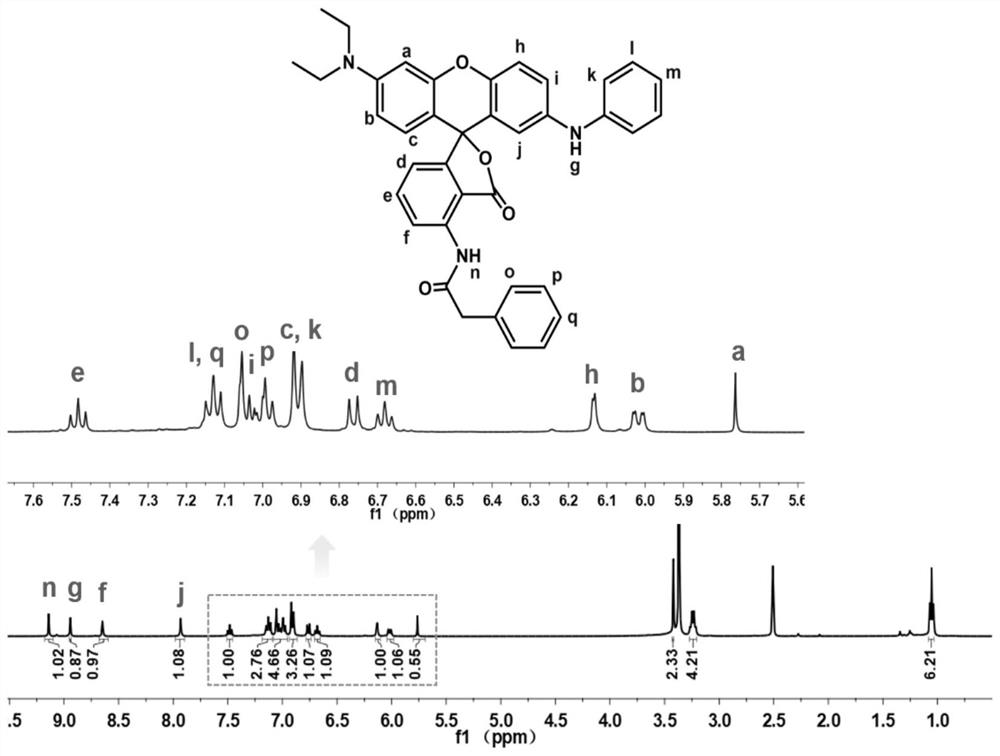

[0069] Put 4-diethylaminonitroketo acid (intermediate M1) (2g) and concentrated sulfuric acid (15ml) into a three-neck flask, and dissolve the powder in an ice-water bath. Then, 4-methoxydiphenylamine (1.11 g) was put into the above-mentioned three-necked flask, and reacted at room temperature for 24 h. Afterwards, the product was slowly dropped into ice water to obtain a dark green precipitate, which was washed with water and sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com