Colorful porcelain plate and preparation method thereof

A kind of colorful, porcelain technology, applied in applications, furniture parts, home appliances, etc., can solve the problems of inability to obtain multi-color effects, flat three-dimensional color layers, inability to achieve fine control of color presentation, etc., and achieve rich and diverse patterns. , rich colors, practicality and durability enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

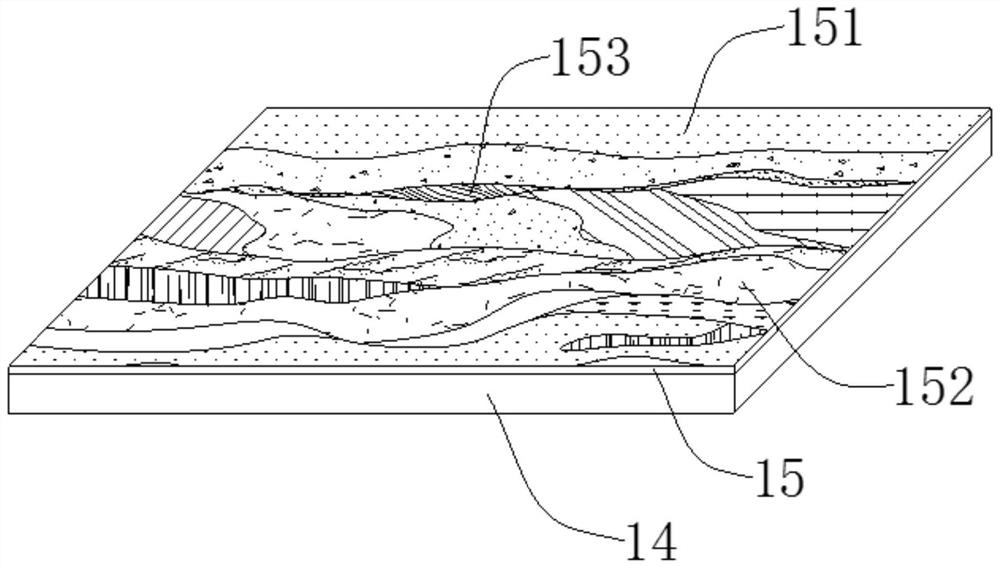

[0135] In this example, using figure 2 The specification of the bell-jar type showering device for preparing colorful porcelain plates is 800mm*2600mm*4.6mm. Concrete preparation process is as follows:

[0136] (1) Select kaolin, feldspar, quartz and other raw sand raw materials and various colored pastes;

[0137] First prepare the green body layer, and weigh the following raw materials: 2 parts of super white sand, 22.5 parts of brocade aluminum sodium sand, 6 parts of medium temperature aluminum sand, 11 parts of potassium sodium water abrasive, 26.5 parts of ball clay, 4.5 parts of bauxite, diluent 3 parts of stone, 4 parts of pyrophyllite, 2 parts of high clay, 10 parts of super white stone powder, 8 parts of clay material, 1 part of super white clay material, 0.3 parts of debonding agent, 0.3 parts of alkali water agent, and 0.3 parts of strengthening agent. The raw material and water are put into a ball mill for ball milling at a ratio of 3:1, and after ball milling,...

preparation Embodiment 2

[0147] The difference between this preparation example and the preparation example 1 is only described here. The difference is that the color matching slurry is blue and yellow, and the blue ingredients are prepared by adding 1% blue pigment to the white slurry to produce blue color. Slurry, yellow ingredients The yellow slurry is formulated by adding 1% yellow pigment to the white slurry, and the obtained colorful porcelain plate is marked as P2.

[0148] Example of performance test

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com