Breathing filler and subsurface flow constructed wetland purification system

A technology for purification systems and constructed wetlands, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of increasing the operation and maintenance costs of constructed wetlands, and achieve the effect of improving the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

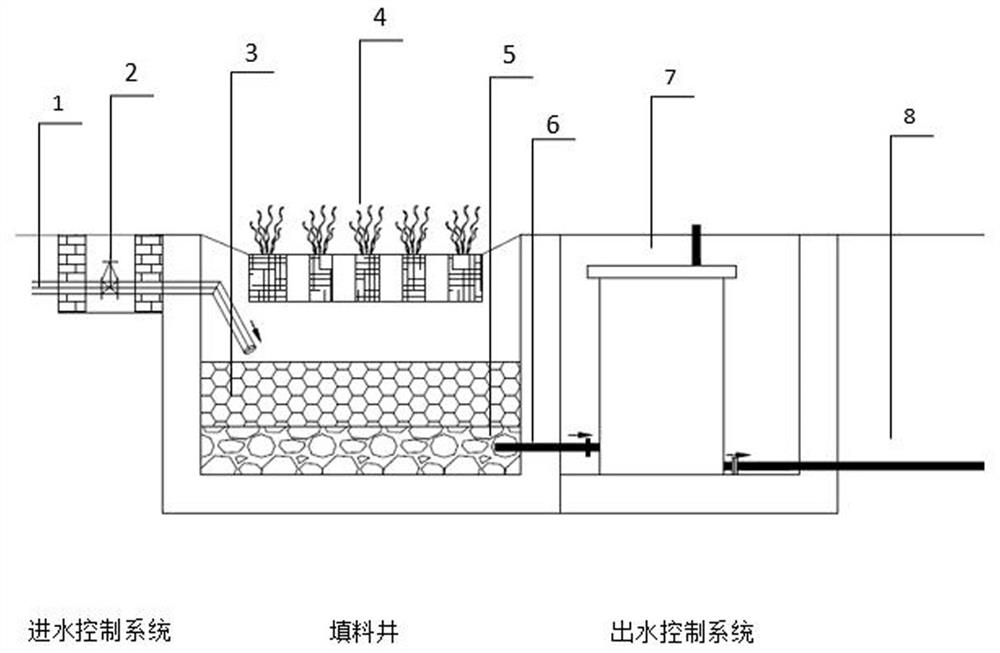

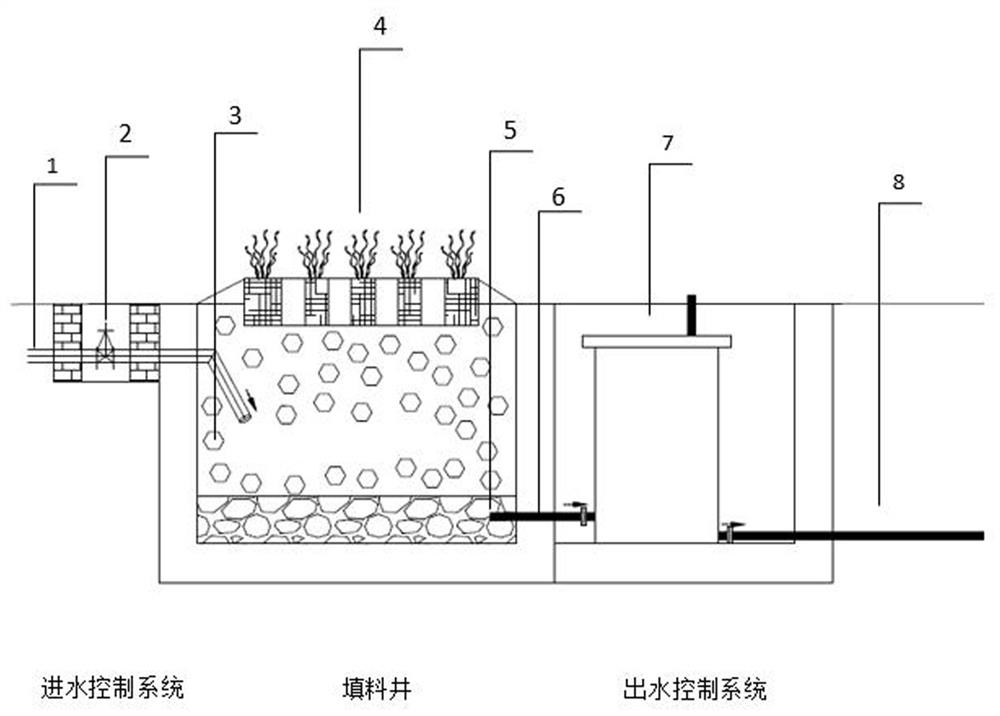

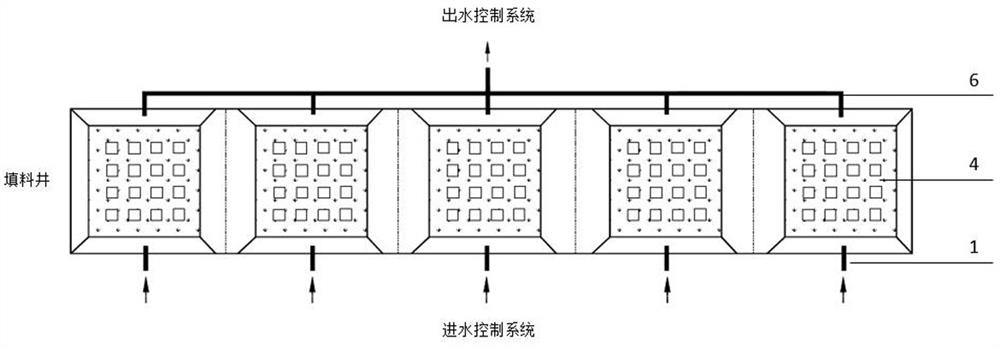

[0026] This embodiment is an underflow constructed wetland purification system, including a water inlet control mechanism, a filling well and a water outlet control mechanism. After the untreated sewage enters the filling well through the water inlet control mechanism, the pollutants in the sewage are absorbed and degraded in the filling well , the purified water is discharged by the water outlet control mechanism.

[0027] In this example, the packing well has a cuboid structure with an internal depth of 1.5m. The inside of the packing well is divided into multiple packing well units by steel wire mesh. The inner bottom of the packing well unit is provided with a pebble supporting layer, and the pebble supporting layer 5 is evenly laid on the At the bottom of the filling well, pebbles with a particle size of 10-15cm are used, and the laying thickness is 0.3m; the upper part of the pebble supporting layer is a breathing packing layer formed by several breathing packings; the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com