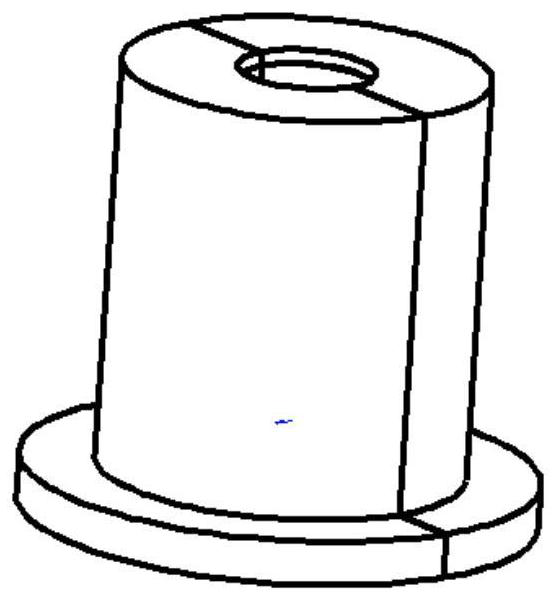

A fixture for alleviating the uneven transition of the outer surface of the pipe-plug structure pressure resistance welding joint

A pressure resistance and welding head technology, which is applied in the field of clamps for relieving the uneven transition of the outer surface of the pressure resistance welding head of the pipe-plug structure, can solve the problems of easily damaged pipes, reduced joint performance, joint stress concentration, etc., and achieves increased fusion. Area, efficient manufacturing efficiency, the effect of realizing manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In this embodiment, pressure resistance welding is performed on the Zr-4 end plug and the CZ pipe on the Gleeble thermal simulator, and the specific steps are as follows:

[0027] 1. Before pressure resistance welding, use #1500 sandpaper to lightly grind the welding end face (6) of the cladding tube, so as to ensure full contact between the cladding tube and the end plug, and prevent the joint from burning due to poor contact. Use absorbent cotton dipped in acetone solution to wipe the oil and impurities on the surface of the workpiece.

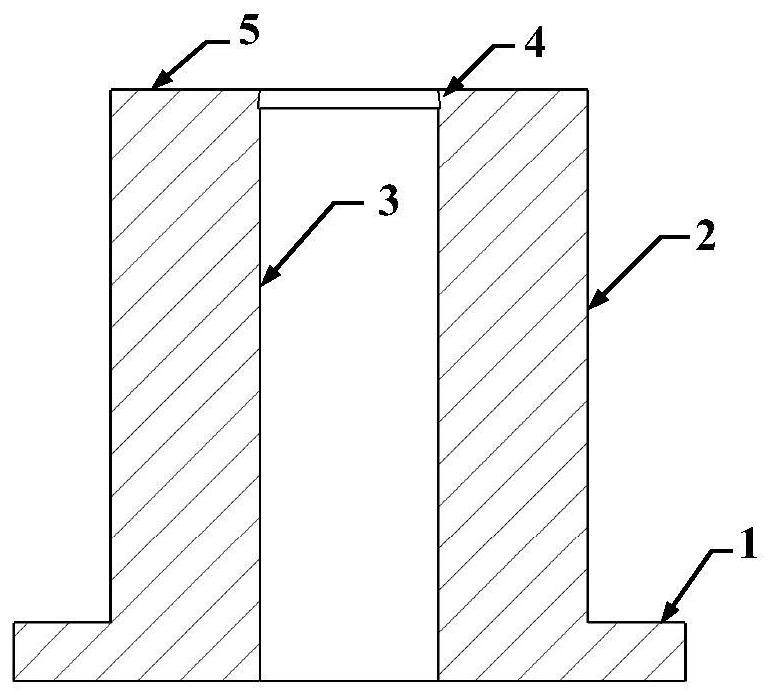

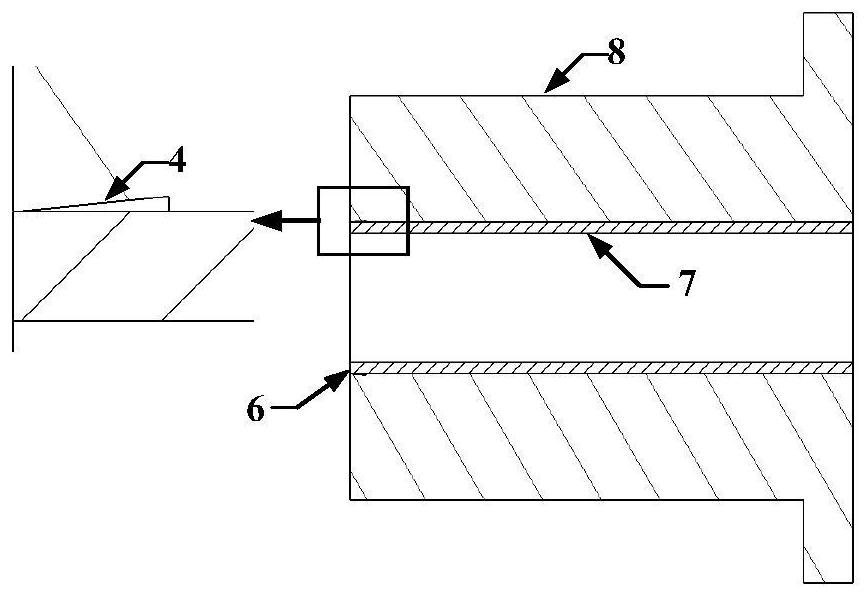

[0028] 2. Clamp the end plug and the pipe respectively inside the corresponding clamps. The pipe is clamped by the clamp (8) with the oblique line segment hole wall. The clamping schematic diagram is as follows image 3 . After the clamping is completed, the hydraulic device is used to push the fixture on the side of the end plug to form a butt joint between the end plug and the pipe, and finally vacuumize.

[0029] 3. Set the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com