Intelligent detection robot for grain purchase and grain classification method

A technology of intelligent detection and robotics, applied in chemical instruments and methods, sorting, solid separation, etc., can solve the problems of uncertainty of detection results, long detection time, high computing power requirements, etc., to achieve objective and true detection results, easy to operate easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

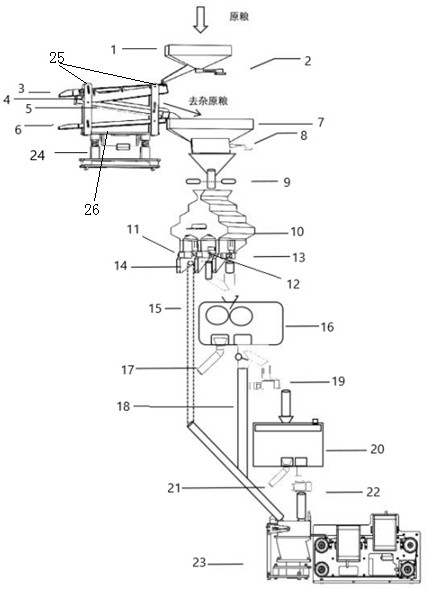

[0044] The embodiment of the present invention builds a set of devices, and by rationalizing the process of detection indicators, the core uses a neural network based on machine vision, supplemented by weighing sensors and radar sensing, to complete the full index detection of "unmanned intervention" for rice purchases : Moisture, impurities, out-of-valley brown rice, mixed varieties, roughness rate, whiteness rate, whole rice rate, yellow grain rate, mildew rate, chalky rate, lesion rate. The detection is accurate, and the detection time is only one tenth of the traditional detection method, and it only takes about 6 minutes to complete the full index detection. Among them, the present invention converts the measurement space of the detected object into the feature space and designs it as a neural network input vector, and completes the automatic detection of relevant indicators.

[0045] Such as figure 1As mentioned above, the intelligent detection robot of the embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com