Fabricated shock absorption and impact resistance ground and mounting method thereof

An impact-resistant, prefabricated technology, applied in the field of building decoration, can solve the problems of non-recycling, long operation cycle, large noise and dust, and achieve the effect of simple installation method, reduced damage and high installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

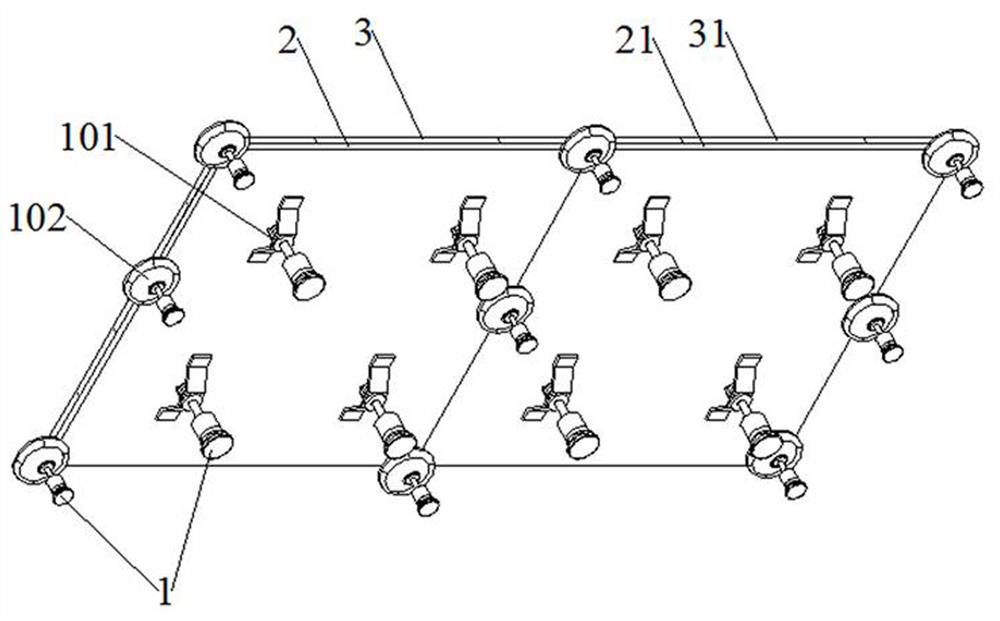

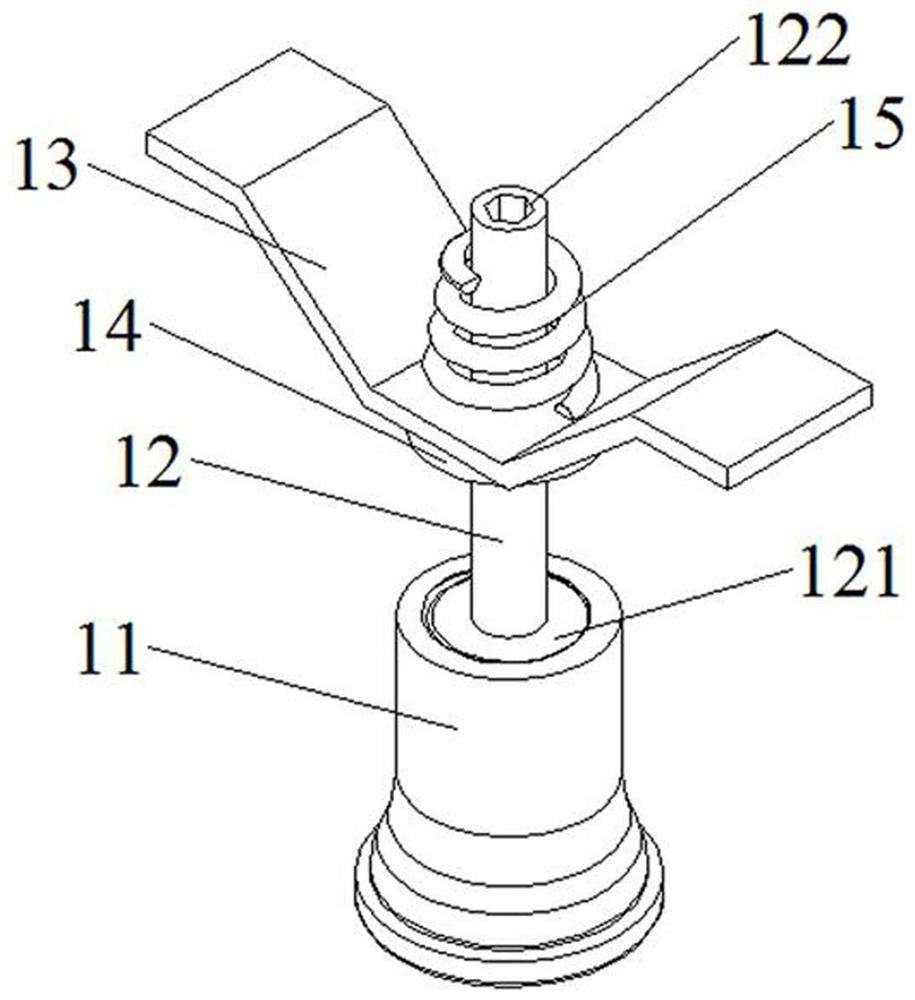

[0039] figure 1 It is a schematic diagram of an assembled shock-absorbing and impact-resistant floor, figure 2 is a schematic diagram of the first overhead assembly, image 3 Schematic diagram for the second overhead assembly, as Figure 1 to Figure 3 As shown, the assembled shock-absorbing and impact-resistant ground is characterized in that it includes an overhead mechanism 1 arranged on the original ground, a moisture-proof substrate 2 arranged on the overhead mechanism 1, and a moisture-proof substrate arranged on the above-mentioned 2 above the floor surface layer 3; the moisture-proof substrate 2 includes a number of substrate units 21 spliced with each other, and the floor surface layer 3 includes a number of panel units 31 spliced with each other; the overhead mechanism 1 includes The first aerial assembly 101 and the second aerial assembly 102; the first aerial assembly 101 and the second aerial assembly 102 both include a leveling base 11, a leveling screw 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com