Parallel type winding coating production line

A coating production line, parallel technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve problems such as unfavorable and efficient production scheduling, low work efficiency, flexible film influence, etc., to improve production Link continuity and production efficiency, the effect of realizing automation and intelligence, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific implementations described here are only used to illustrate and explain the present invention, not to limit the present invention.

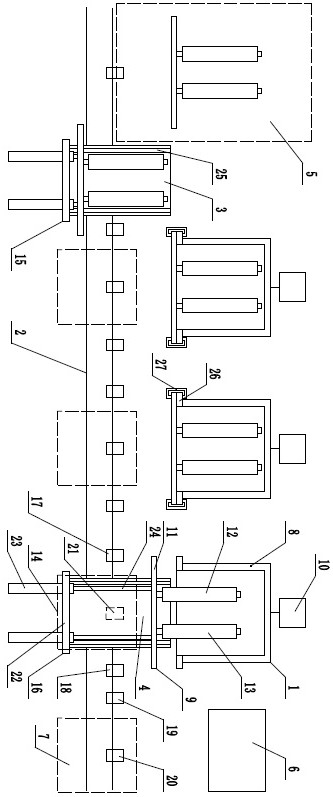

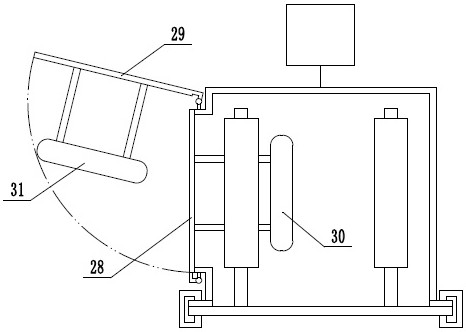

[0032] figure 1 It is a schematic top view of an embodiment of the parallel winding coating production line of the present invention. As shown in the figure, a parallel winding coating production line of the present invention mainly includes a winding coating machine 1, a track 2, a moving Trolley one 3, mobile trolley two 4, operation area 5 and control center 6; operation area 5 is located at one end of the track, and a pause area 7 is set at the other end of the track; more than 2 winding coating machines are arranged on the track of one side. exist figure 1 In the case shown, the web coating line includes 3 web coating machines. The roll-to-roll coating machine includes a coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com