Antibacterial and antiviral polymer compositions, polymer blend, and film product

A polymer and composition technology, applied in the field of functional polymer materials, can solve the problems of weak antibacterial and antiviral properties, and achieve the effects of excellent antibacterial, avoiding uneven dispersion and good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

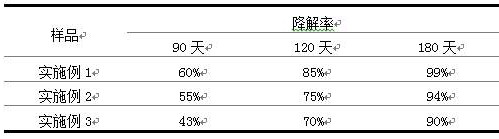

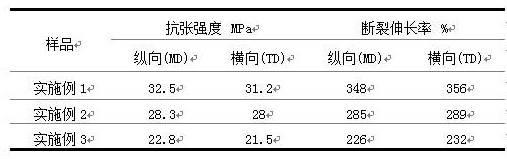

[0038] Example 1 Preparation of biodegradable antibacterial and antiviral functional films

[0039]Step 1: Dissolve 6 g of antibacterial agent (the ratio of antimicrobial peptide to monolauric acid monoglyceride is 1:9, the antimicrobial peptide uses the product of Peptide 601125, the molecular weight is 2202.5, and the purity is ≥98%) in 500 ml of ethanol, magnetically Stir and heat to 55°C, add 70 g of calcium carbonate, stir well, cool to room temperature, and filter under reduced pressure to obtain a filter cake, which is powdered with a mortar, then add 500 ml of acetic acid solution with a mass percentage of 30%, and heat Fully dissolve at 60°C, quickly add 10 g of antioxidant 1010, 30 g of coupling agent KH550, and 5 g of compatibilizer (the ratio of ADR-4368 to isocyanate IPDI is 3:2) under the condition of mechanical stirring at 2000 rpm, Subsequently, the pH of the solution was adjusted to 7 with NaOH, filtered under reduced pressure, dried in a vacuum oven for 24 h,...

Embodiment 2

[0043] Embodiment 2 Preparation of biodegradable antibacterial and antiviral functional films

[0044] Step 1: Dissolve 3 g of antibacterial agent (the ratio of antimicrobial peptide to monolauric acid monoglyceride is 3:7, and the type of antimicrobial peptide is the same as in Example 1) in 500 ml of ethanol, heat to 55°C with magnetic stirring, and add 30 g Calcium carbonate and 10 g of lignin were stirred thoroughly, cooled to room temperature, and filtered under reduced pressure to obtain a filter cake, which was made into a powder in a mortar, then 500 ml of acetic acid solution with a mass percentage of 30% was added, and heated to 60°C to fully Dissolve, quickly add 5 g antioxidant 1076, 20 g coupling agent KR-TTS, 10 g compatibilizer (isocyanate TDI) under the condition of mechanical stirring at 1500 rpm, then adjust the pH of the solution to 7 with NaOH, pump under reduced pressure After filtering, put it in a vacuum oven to dry for 24 h, take it out and pulverize it...

Embodiment 3

[0048] Example 3 Preparation of biodegradable antibacterial and antiviral functional films

[0049] Step 1: Dissolve 5 g of antibacterial agent (the ratio of antimicrobial peptide to monolauric acid monoglyceride is 1:1, and the type of antimicrobial peptide is the same as in Example 1) in 500 ml of isopropanol, heat to 55°C with magnetic stirring, and add 30 g of calcium carbonate and 20 g of silicon dioxide were stirred thoroughly, cooled to room temperature, and filtered under reduced pressure to obtain a filter cake, which was powdered in a mortar, and then 500 ml of acetic acid solution with a mass percentage of 30% was added and heated to Fully dissolve at 60°C, quickly add 8 g of antioxidant 1010, 25 g of coupling agent KH550, and 8 g of compatibilizer (the ratio of AX8900 to isocyanate MDI is 3:2) under the condition of mechanical stirring at 1500 rpm, followed by NaOH The pH of the solution was adjusted to 7, filtered under reduced pressure, dried in a vacuum oven for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight distribution index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com