Multilayer non-woven fabric for disinfection and use method thereof

A non-woven and disinfectant technology, applied in the field of non-woven fabrics, can solve the problems of increasing the corrosion possibility of disinfectants to disinfected objects, reducing the turnover efficiency of medical devices, and reducing the disinfection efficiency of medical devices, etc., to achieve good technical feasibility and efficiency. Economic value, realization of disinfection work, effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

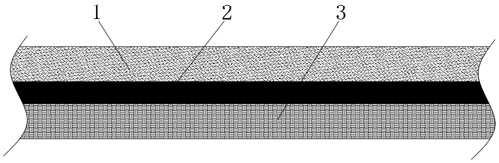

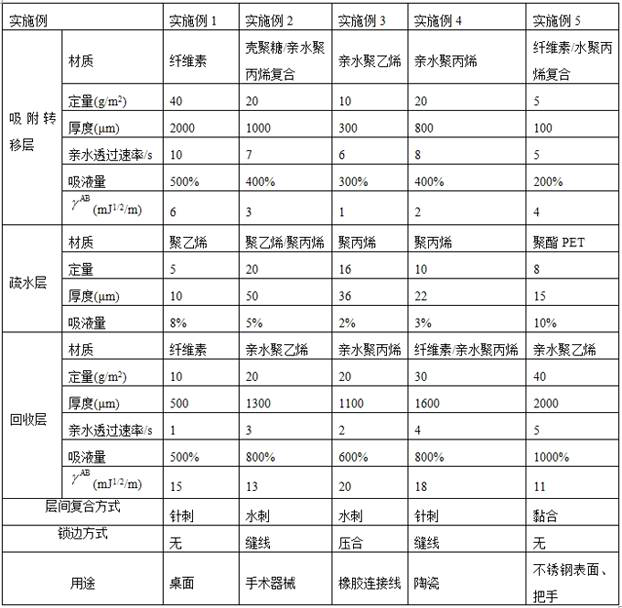

[0036] The whole multi-layer non-woven fabric for disinfection is in the shape of a square sheet without seaming. This product is used for the disinfection of wooden tabletops, including the disinfectant absorption and transfer layer 1, the hydrophobic layer 2 and the disinfectant recovery layer 3, which are stacked in sequence. Taking the measurement method in GB / T 24218.6-2010 as the standard, the disinfectant absorption and transfer layer 1 The liquid absorption X is 500%, the liquid absorption Y of the disinfectant recovery layer 3 is 500%, and the liquid absorption Y of the hydrophobic layer 2 is 8%.

[0037] The non-woven fabric in the disinfectant absorption transfer layer 1 is quantitatively 40g / m 2 , the hydrophilic permeation speed is 10s, and the hydrophilicity index is 6(mJ 1 / 2 / m), the thickness is 2000 μm; the non-woven fabric in the disinfectant recovery layer 3 is quantitatively 10g / m 2 , the hydrophilic permeation speed is 1s, and the hydrophilicity index is...

Embodiment 2

[0039] The multi-layer non-woven fabric for disinfection is in the shape of a rectangular sheet as a whole, and the edges are locked by stitching. This product is used for the disinfection of the surface of surgical instruments, including the disinfectant solution adsorption transfer layer 1, the hydrophobic layer 2 and the disinfectant recovery layer 3, which are sequentially stacked. Based on the measurement method in GB / T 24218.6-2010, the disinfectant solution adsorption transfer layer The liquid absorption capacity X of 1 is 400%, the liquid absorption capacity Y of the disinfectant recovery layer 3 is 800%, and the liquid absorption capacity of the hydrophobic layer 2 is 5%.

[0040] The non-woven fabric in the disinfectant absorption transfer layer 1 is quantitatively 20g / m 2 , the hydrophilic permeation speed is 7s, and the hydrophilicity index is 3(mJ 1 / 2 / m), the thickness is 1000 μm; the non-woven fabric in the disinfectant recovery layer 3 is quantitatively 20g / m ...

Embodiment 3

[0042] The multi-layer non-woven fabric for disinfection is in the shape of a rectangular sheet as a whole, and the edges are locked by pressing. This product is used for the disinfection of ultrasonic probes connected to the rubber pipeline of the monitor, including the disinfectant solution adsorption transfer layer 1, the hydrophobic layer 2 and the disinfectant recovery layer 3, which are sequentially stacked. The liquid absorption X of the adsorption transfer layer 1 is 300%, the liquid absorption Y of the disinfectant recovery layer 3 is 600%, and the liquid absorption Y of the hydrophobic layer 2 is 2%.

[0043] The non-woven fabric in the disinfectant absorption transfer layer 1 is quantitatively 10g / m 2 , the hydrophilic permeation speed is 6s, and the hydrophilicity index is 1(mJ 1 / 2 / m), the thickness is 300 μm; the non-woven fabric in the disinfectant recovery layer 3 is quantitatively 20g / m 2 , the hydrophilic permeation speed is 2s, and the hydrophilicity index...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com