Resin-impregnated functionalized wood and processing technology

A resin impregnation and processing technology, applied in the field of wood, can solve the problems of high free formaldehyde content, uneven resin diffusion, and high risk of moth-eaten, and achieve the effects of less free formaldehyde, improved improvement effect, and low risk of moth-eaten

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

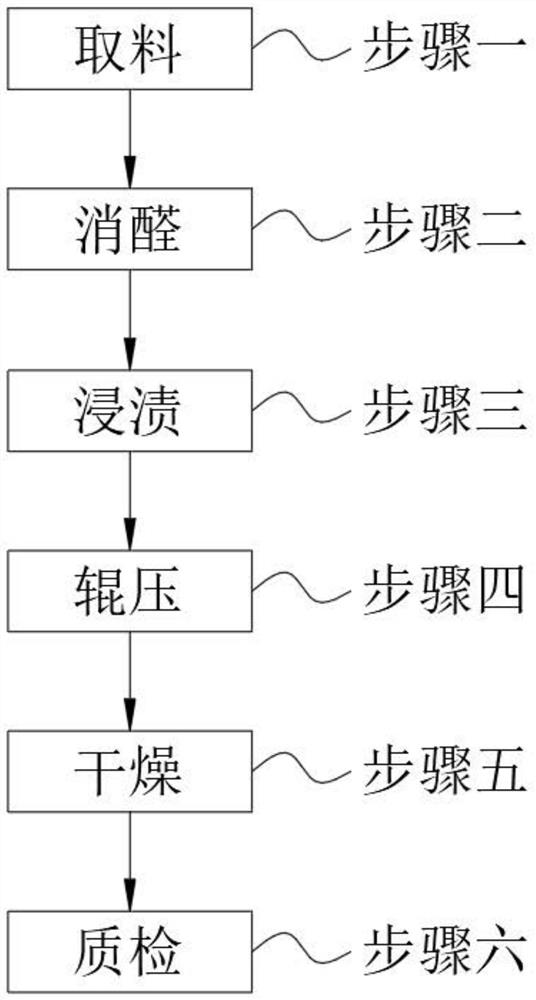

Image

Examples

Embodiment 1

[0028] Resin impregnated functionalized wood, the formula includes: finished wood, water-soluble low molecular weight phenolic resin, defoamer, anti-formaldehyde agent, dispersant, coupling agent, insect repellant and curing agent; the parts by weight of each component are respectively: 82-90 parts of finished wood, 40-48 parts of water-soluble low molecular weight phenolic resin, 1-3 parts of defoaming agent, 5-9 parts of anti-formaldehyde agent, 2-4 parts of dispersant, 1-3 parts coupling agent, 6-10 parts of insect repellent and 1-3 parts of curing agent, the water-soluble low-molecular-weight phenolic resin is prepared by mixing phenol, formaldehyde and sodium hydroxide in a molar ratio of 1:2.1:0.1, and Adjust the pH value to 5.8, and the formaldehyde elimination agent is prepared by mixing urea, semicarbazide, hydrogen peroxide and hypochlorous acid, and the weight ratio of urea, semicarbazide, hydrogen peroxide and hypochlorous acid is 2:1:3: 2. The insect repellant is ...

Embodiment 2

[0037]Resin impregnated functionalized wood, the formula includes: finished wood, water-soluble low molecular weight phenolic resin, defoamer, anti-formaldehyde agent, dispersant, coupling agent, insect repellant and curing agent; the parts by weight of each component are respectively: 82-90 parts of finished wood, 40-48 parts of water-soluble low molecular weight phenolic resin, 1-3 parts of defoaming agent, 5-9 parts of anti-formaldehyde agent, 2-4 parts of dispersant, 1-3 parts coupling agent, 6-10 parts of insect repellent and 1-3 parts of curing agent, the water-soluble low-molecular-weight phenolic resin is prepared by mixing phenol, formaldehyde and sodium hydroxide in a molar ratio of 1:2.1:0.1, and Adjust the pH value to 5.8, and the formaldehyde elimination agent is prepared by mixing urea, semicarbazide, hydrogen peroxide and hypochlorous acid, and the weight ratio of urea, semicarbazide, hydrogen peroxide and hypochlorous acid is 2:1:3: 2. The insect repellant is p...

Embodiment 3

[0046] Resin impregnated functionalized wood, the formula includes: finished wood, water-soluble low molecular weight phenolic resin, defoamer, anti-formaldehyde agent, dispersant, coupling agent, insect repellant and curing agent; the parts by weight of each component are respectively: 82-90 parts of finished wood, 40-48 parts of water-soluble low molecular weight phenolic resin, 1-3 parts of defoaming agent, 5-9 parts of anti-formaldehyde agent, 2-4 parts of dispersant, 1-3 parts coupling agent, 6-10 parts of insect repellent and 1-3 parts of curing agent, the water-soluble low-molecular-weight phenolic resin is prepared by mixing phenol, formaldehyde and sodium hydroxide in a molar ratio of 1:2.1:0.1, and Adjust the pH value to 5.8, and the formaldehyde elimination agent is prepared by mixing urea, semicarbazide, hydrogen peroxide and hypochlorous acid, and the weight ratio of urea, semicarbazide, hydrogen peroxide and hypochlorous acid is 2:1:3: 2. The insect repellant is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com