Automatic pipe centered-positioning device and application method thereof

A centering positioning and automatic centering technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unguaranteed assembly quality, low degree of automation, high labor intensity, etc., to achieve high commercial and utilization value, High degree of automation and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

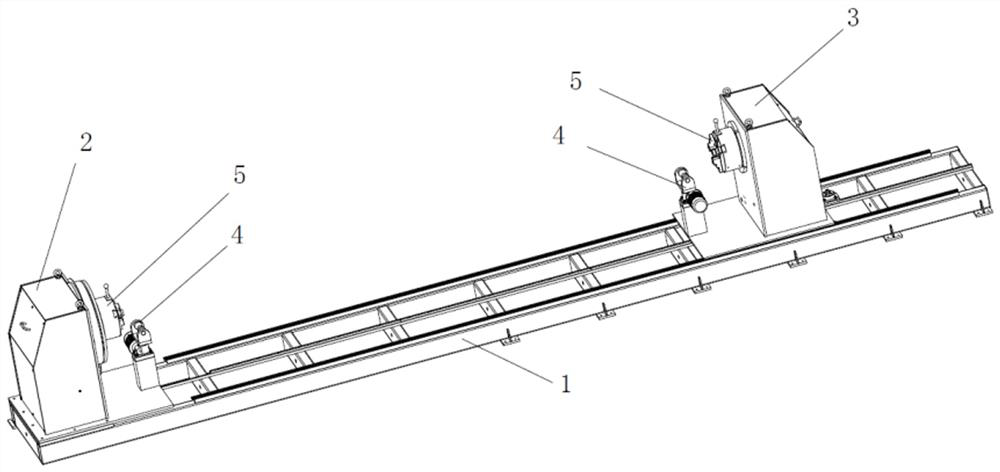

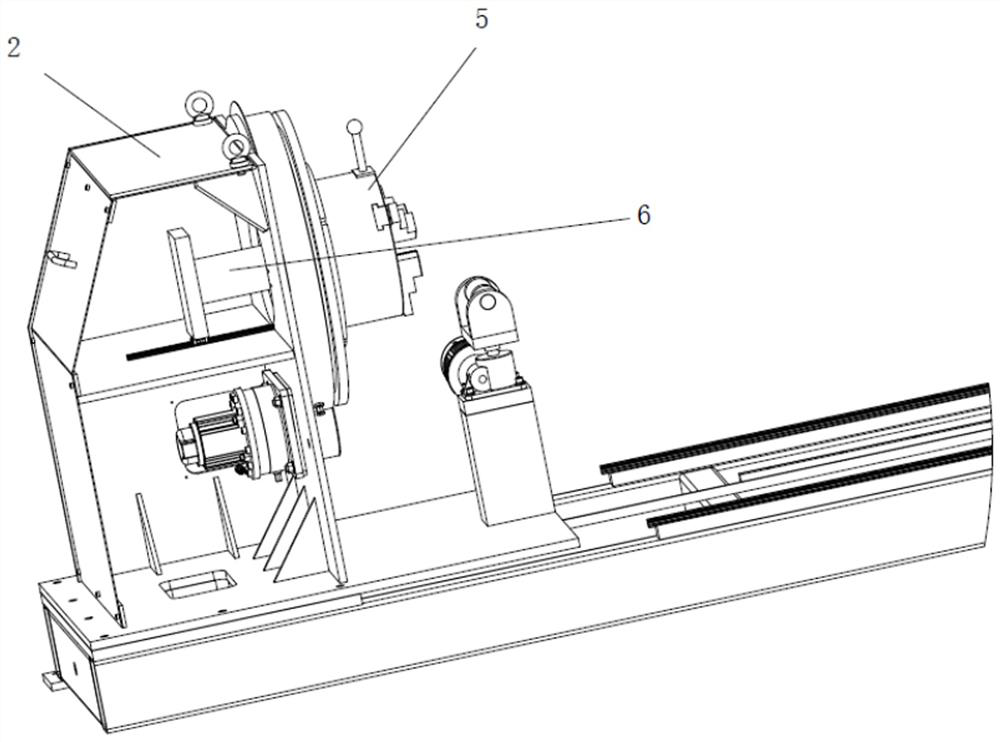

[0031] Automatic positioning device comprises a mount, a fixing table side of the mounting means, the mounting table moving mechanism is provided slidable; a fixed-side holding device and the fixed-side fixing means supporting means, moving means is provided on the fixed-side supporting means holding the movable side holding means, the movable supporting means cooperating with the fixed-side supporting means, and the fixed-side holding means connected to the movable side holding means for positioning the detection means are .

[0032] Detecting means for positioning and fixing mechanism provided in the hollow shell moving mechanism for positioning the detection means comprises a detection head for positioning and locating the detection of the end bracket, for positioning the test head by the positioning of the adsorbent positioning base end connected to the detection, location detection of the end housing connected to the housing fixing means and the moving means. The intermediate...

Embodiment 2

[0035] Shows a tube used in the method for automatic positioning device, which differs from the prior art in that: using a method comprising the steps of: a, according to the first pipe length adjusting means and a fixing means from the position for the tube end or one side bilateral end fitting requirements for automatic positioning, pre-selected attachment fitting disposed on a single side end of the fixed-side tube or the holding means are fixed to the tube side of the double-sided end, the movable holding means, the tube is placed on the fixed bearing side the holder-side supporting means and the moving means; B, the fixed-side supporting means and the moving side pipe supporting means for automatically adjusting the center line and the fixed side, the center line of the movable clamping device is placed on the fixed side and moving side clamp accessory means mounted on the center line coincides, in particular, where the fixed side, the movable supporting devices each having a...

Embodiment 3

[0039] In a particular embodiment of the mounting table clamped on the ground, mounted on a table surface is provided with a movable rail arrangement with a moving mechanism 3. Fixing means 2 and the moving mechanism 3 are laid on the surface of the mounting table 1, are disposed at both sides of the mounting table 1.

[0040] 5 holding means in pairs, respectively, fixed-side holding means and the moving-side clamping device, two clamping means are arranged at the outer end plate fixing means and the moving mechanism 2 to 3, as a flange or sleeve fixing means. Fixed side, facing the movable clamping means 5 are arranged on the fixing means 2 and the moving mechanism 3, and the position of the center hole coincides. Fixed side, the movable clamping means 5 has a hollow structure, the outer end face of each clamping jaw has a plurality of cloth cloth, forward and backward clamping jaw can be synchronized together securely holding the flange or sleeve.

[0041] Supporting means 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com