Printed circuit board, finished circuit board and welding method

A technology of printed circuit boards and circuit boards, applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., can solve problems such as poor welding, and achieve the effect of solving poor welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

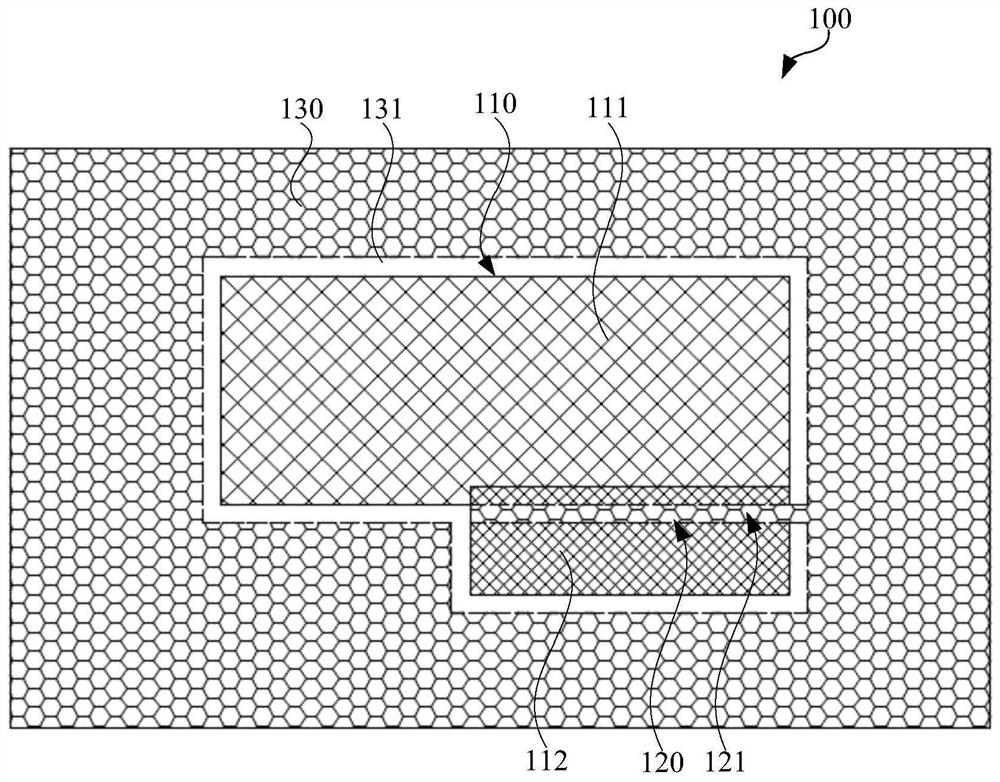

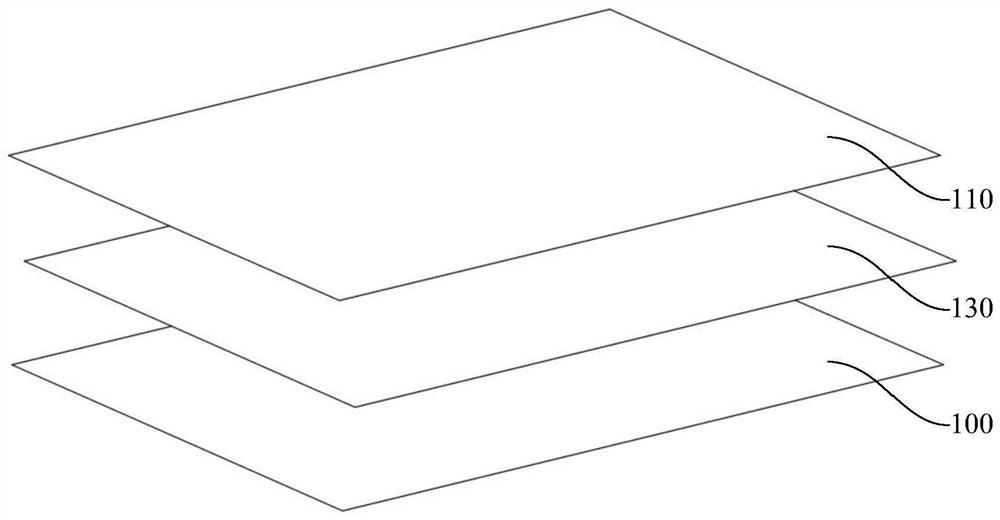

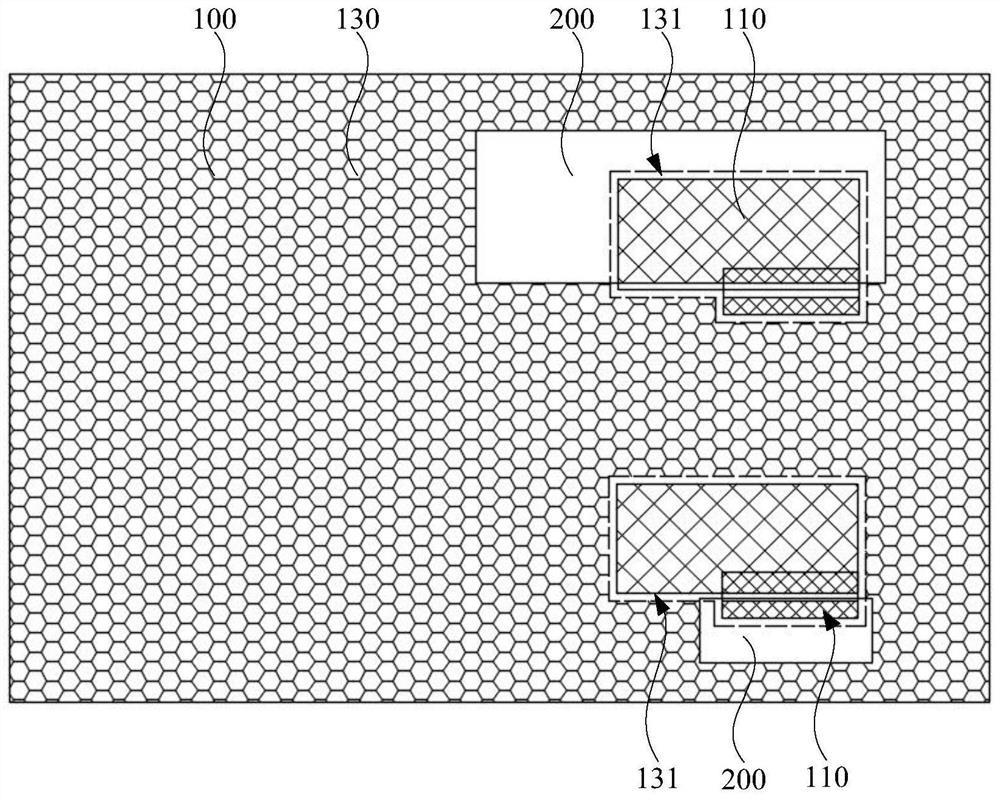

[0040] figure 1 The structural representation of the printed circuit board provided by the present invention, figure 2 A schematic diagram of the composition and structure of the printed circuit board provided by the present invention, image 3 The structural representation of the finished circuit board provided by the present invention, Figure 4 It is a schematic diagram of the soldering positions of two electronic devices on the finished circuit board provided by the present invention.

[0041] Such as Figure 1-4 As shown, a printed circuit board provided by the present invention includes a circuit board body 100 and at least one composite pad 110 located on the circuit board body 100. The composite pad 110 has a slit 120 to divide the composite pad 110 into The first soldering portion 111 and the second soldering portion 112 are connected to each other; the gap 120 is covered with a soldering resist 121; The window 131 corresponding to the second welding portion 112 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com