Method for measuring content of calcium hydroxide in flue gas desulfurizer

A technology of calcium hydroxide and determination method, applied in the field of chemical analysis, can solve problems such as inaccurate detection results, achieve the effects of accurate measurement, small error, and solve the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

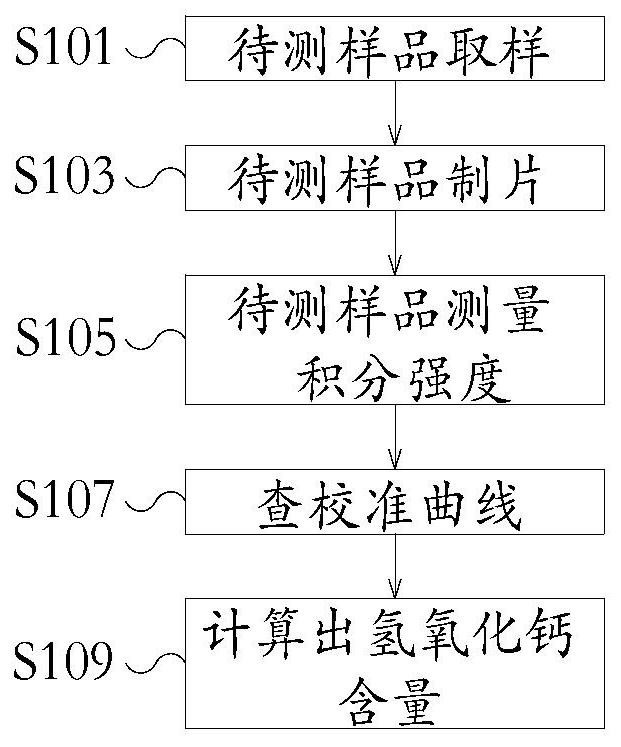

[0040] Step S101: Sampling of samples to be tested:

[0041] Sampling 2 times respectively from the incoming flue gas desulfurizer as the sample 1# to be tested and the sample 2# to be tested.

[0042] Step S103: Preparation of samples to be tested:

[0043] Scrub the agate mortar with a cotton ball of absolute ethanol and dry it;

[0044] In the agate mortar, grind the sample to be tested 1# and the sample to be tested 2# in the agate mortar to a particle size of less than 10 μm;

[0045] The above ground test sample 1# and test sample 2# were pressed into tablets respectively.

[0046] Step S105: Measure the integral intensity of the sample to be tested:

[0047] Adjust the X-ray diffractometer to make it reach the stable state required for measurement;

[0048] Under the same diffraction conditions as the determination of the standard sample calcium hydroxide phase integral intensity, measure the integral intensity of the calcium hydroxide phase of the test sample 1# and ...

Embodiment 2

[0055] Step S101: Sampling of samples to be tested:

[0056] Quickly extract 2 samples of the mixture produced by the desulfurization reaction at the production site as the test sample 3# and the test sample 4#.

[0057] Step S103: Preparation of samples to be tested:

[0058] Scrub the agate mortar with a cotton ball of absolute ethanol and dry it;

[0059] Grind the sample to be tested 3# and the sample to be tested 4# respectively in an agate mortar until the particle size is less than 10 μm;

[0060] The above-mentioned ground samples to be tested are respectively pressed into tablets;

[0061] Step S105: Measure the integral intensity of the sample to be tested:

[0062] Adjust the X-ray diffractometer to make it reach the stable state required for measurement;

[0063] Under the same diffraction conditions as the determination of the standard sample calcium hydroxide phase integral intensity, measure the integral intensity of the calcium hydroxide phase of the test s...

Embodiment 3

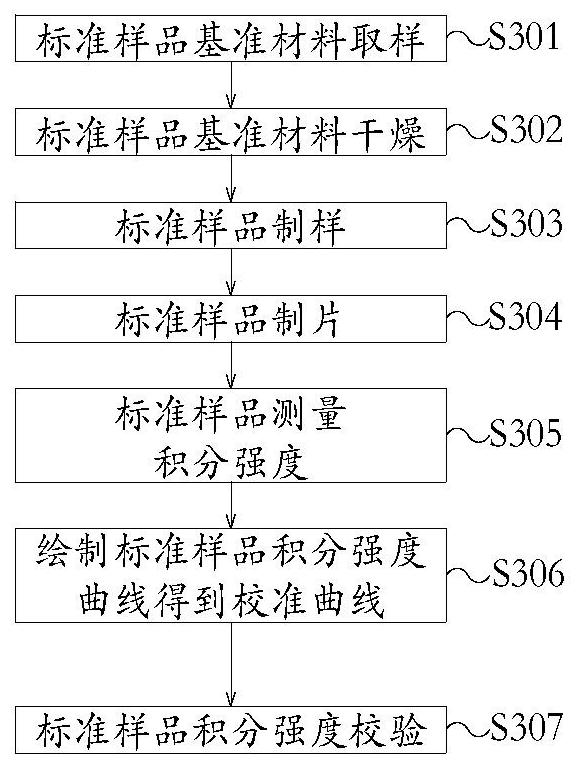

[0070] figure 2 A schematic flow chart of a standard sample calibration curve drawing method provided in the embodiment of the present invention; figure 2 As shown, the method includes steps S301-S307:

[0071] Step S301: Sampling of standard samples and reference materials. The reference materials in this embodiment are reference calcium carbonate and reference calcium hydroxide.

[0072] Step S302: standard sample reference material drying:

[0073] Put the reference calcium carbonate and reference calcium hydroxide in weighing dishes respectively, put them in an oven and dry them at 105°C for about 1 hour, take them out and place them in a desiccator to cool naturally to room temperature.

[0074] It should be noted that the above-mentioned drying temperature of 105° C. and drying time of 1 hour are only set for the purpose of drying in this embodiment, including but not limited to the above-mentioned set values.

[0075] Step S303: Sample preparation of standard sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com