A guide tube and crystal pulling furnace

A technology of guide tube and crystal pulling furnace, which is applied in the field of silicon wafer processing, and can solve the problems of reduced economic benefits, separation of components of the guide tube, and inability to replace components separately, so as to reduce the cost of use and avoid adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

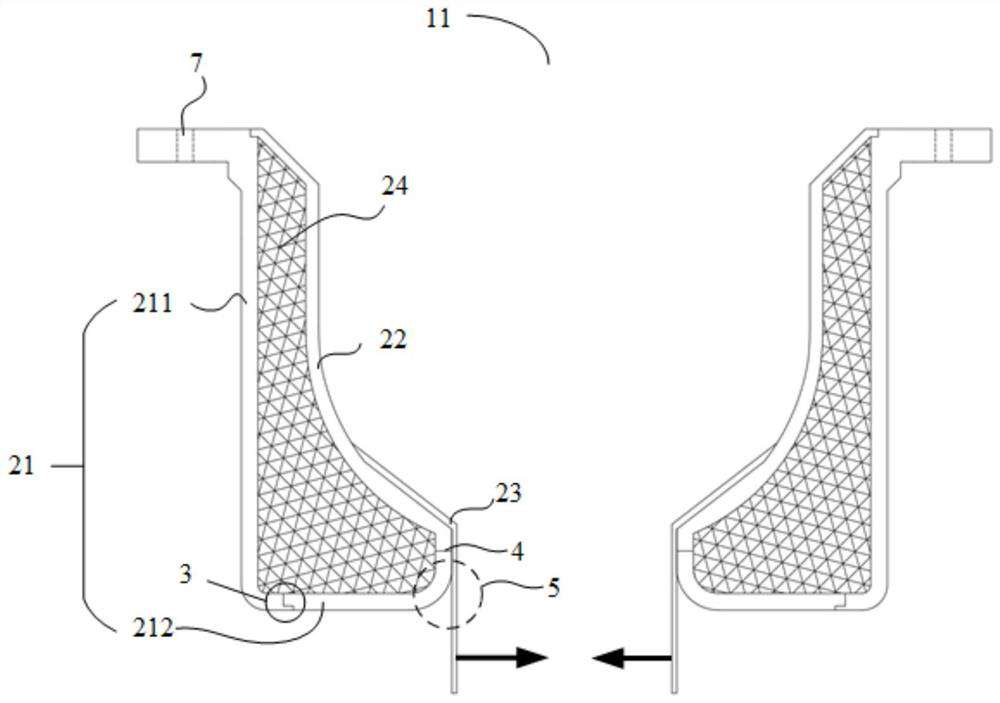

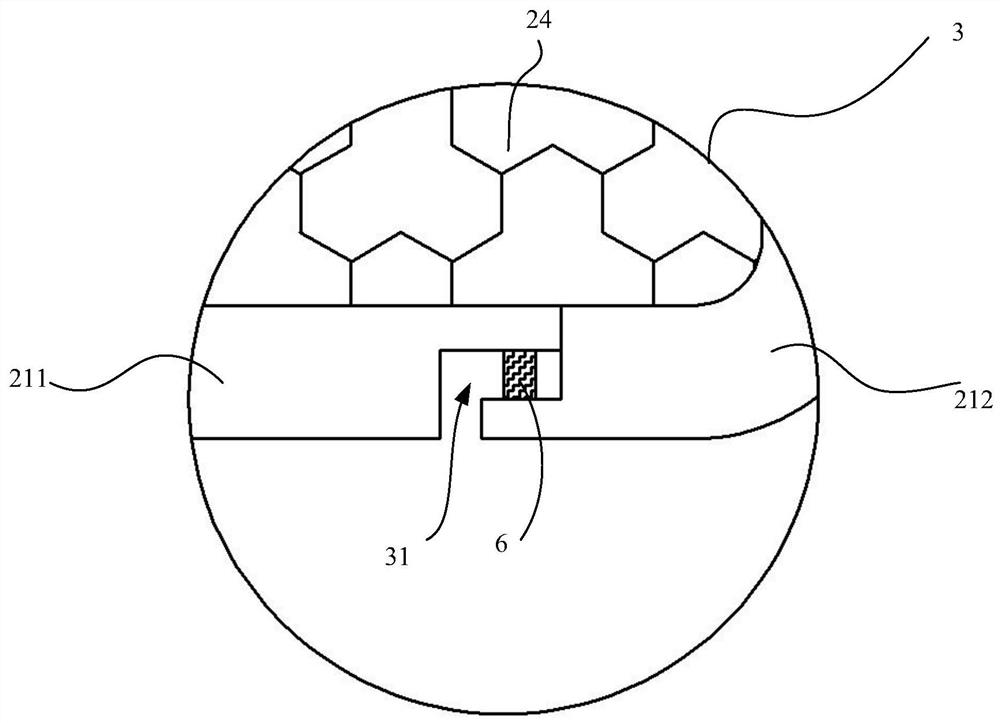

[0021] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

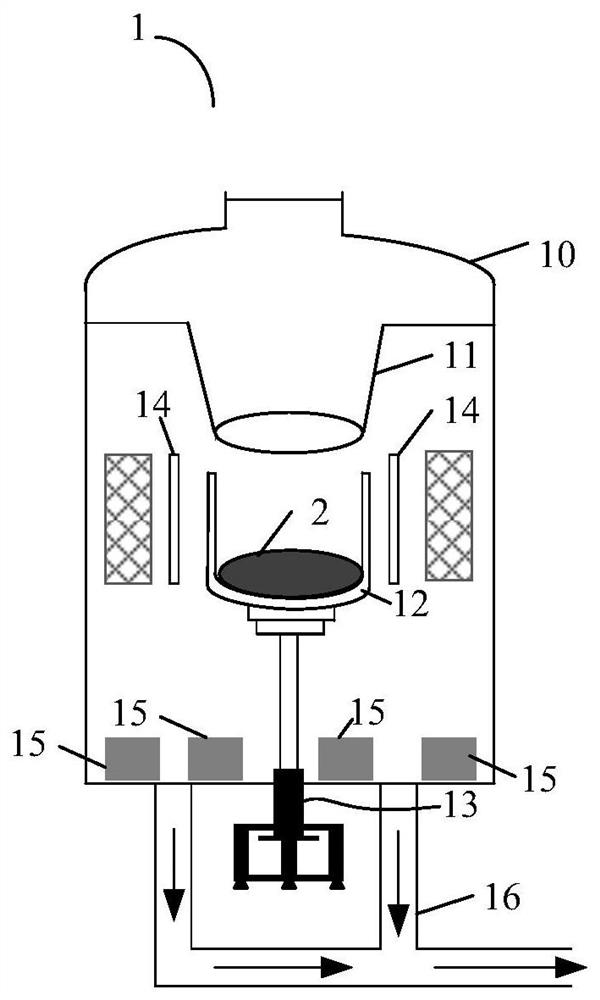

[0022] see figure 1 , which shows a schematic structural diagram of an exemplary crystal pulling furnace 1 used to manufacture a single crystal silicon rod by the Czochralski method. figure 1 The shown crystal pulling furnace 1 may at least include: a furnace body 10, a guide tube 11, a quartz crucible 12 containing polycrystalline silicon raw materials (or polycrystalline silicon melt), and a quartz crucible 12 for driving the movement and The rotating mechanical part 13, in addition, may also include a heater 14 for heating the polysilicon raw material to form the polysilicon melt 2, a bottom insulating material 15 provided at the bottom end of the furnace body 10, and an exhaust port duct 16, wherein the exhaust gas The exhaust direction of the port duct 16 is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com