A kind of hot-rolled steel strip for carriage plate and preparation method thereof

A technology of hot-rolled steel strip and carriage plate, which is applied in the field of hot-rolled steel strip for carriage and its preparation, and can solve the problems of increased sensitivity of the surface quality of the steel plate, no breakthrough in surface quality, peeling and powdering of the surface iron sheet, etc. Achieve the effect of excellent plate shape and cold bending performance, increase strength and reduce TiN content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

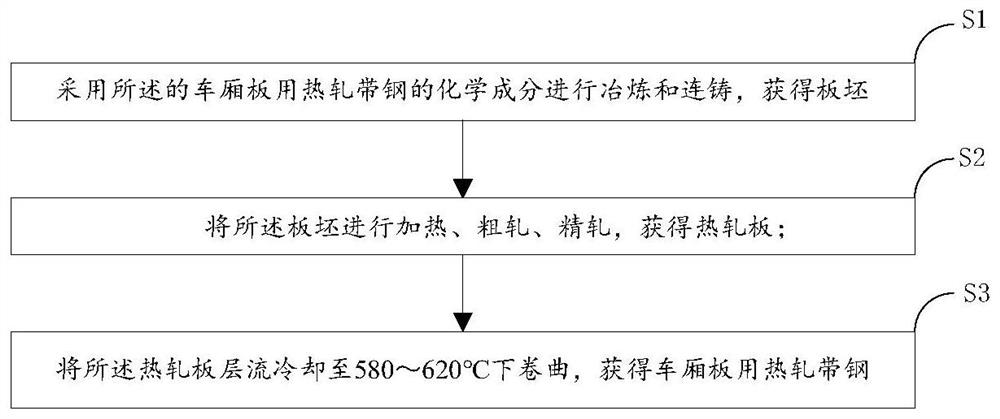

[0044] The present invention also provides a preparation method of the hot-rolled steel strip for the carriage plate, the preparation method comprising:

[0045]S1, using the chemical composition of the hot-rolled steel strip for the carriage plate to carry out smelting and continuous casting to obtain a slab;

[0046] S2, heating the slab, rough rolling, and finish rolling to obtain a hot-rolled plate;

[0047] In step S2,

[0048] The slab is heated by a heating furnace, the furnace temperature is 1200-1260°C, and the furnace time is 170-300min; this temperature range is conducive to the remelting of Nb\Ti composite strengthening elements, and the low temperature is not conducive to the remelting of alloying elements , Excessively high furnace temperature is not conducive to burning loss, surface quality and tissue control.

[0049] Control the rough rolling termination temperature RT2 to be 980-1080°C; if the temperature is too high, the surface quality and structure will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com