Automatic maintenance device and method for fan foundation concrete

A technology for fan foundation and concrete, applied in measuring devices, instruments, etc., can solve the problems of heavy labor, difficult to guarantee maintenance quality, and errors in watering time points, and achieve the effect of good maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

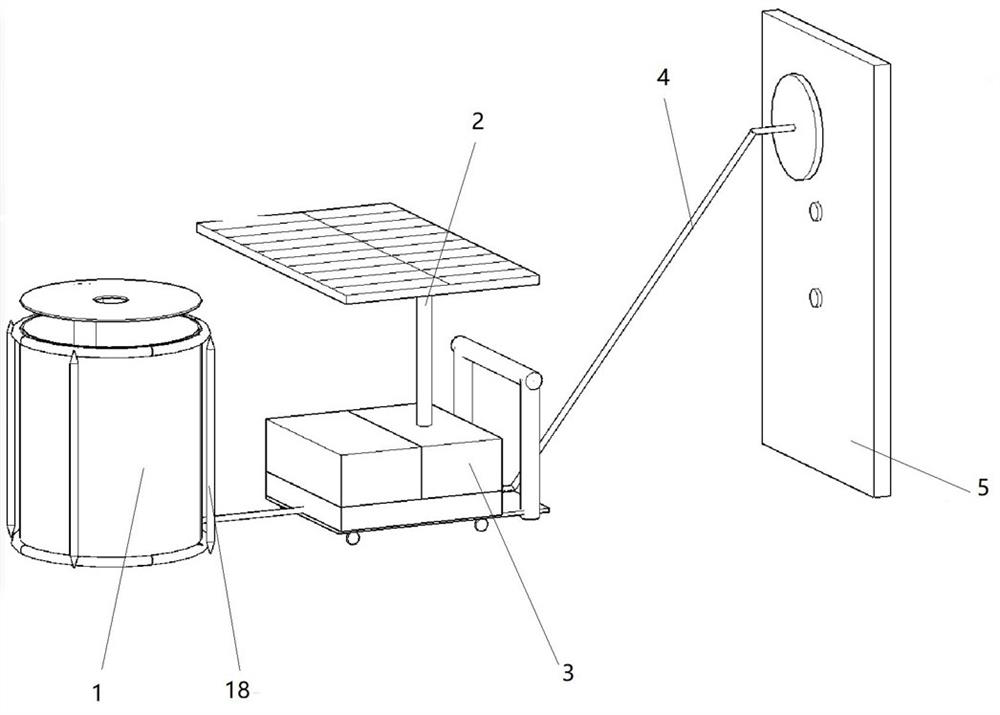

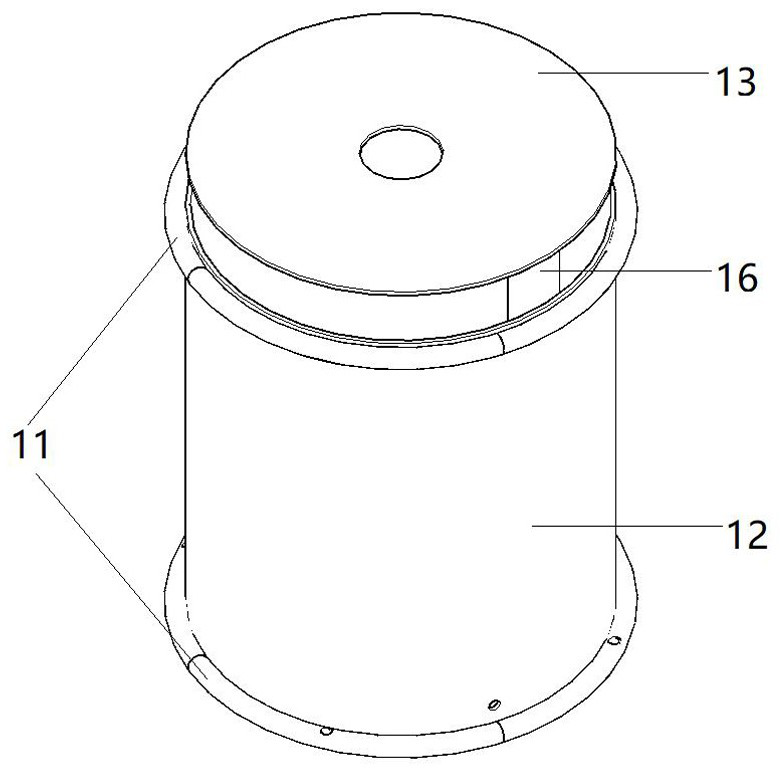

[0046] Embodiment one, such as figure 1 As shown in the figure, the structure diagram of an embodiment of an automatic maintenance device for fan foundation concrete of the present application is shown in the figure. The automatic maintenance device for fan foundation concrete shown in the figure includes a water storage system 1, a power supply system 2, an electric control system 3 and spray system 4, the water storage system 1 includes a water tank, a water tank bracket, the water tank includes a box body 12 and a box cover 13, the box cover 13 is provided with a water inlet, and the box body 12 is provided with Water outlet, the water outlet is set at the bottom of the side wall of the box body 12 or is set at the bottom surface of the box body 12, the water tank bracket includes an upper and lower support frame 11 and a box body support rod 18, and the upper and lower support frame 11 are respectively arranged on the top and bottom of the box body 12, the upper and lower ...

Embodiment 2

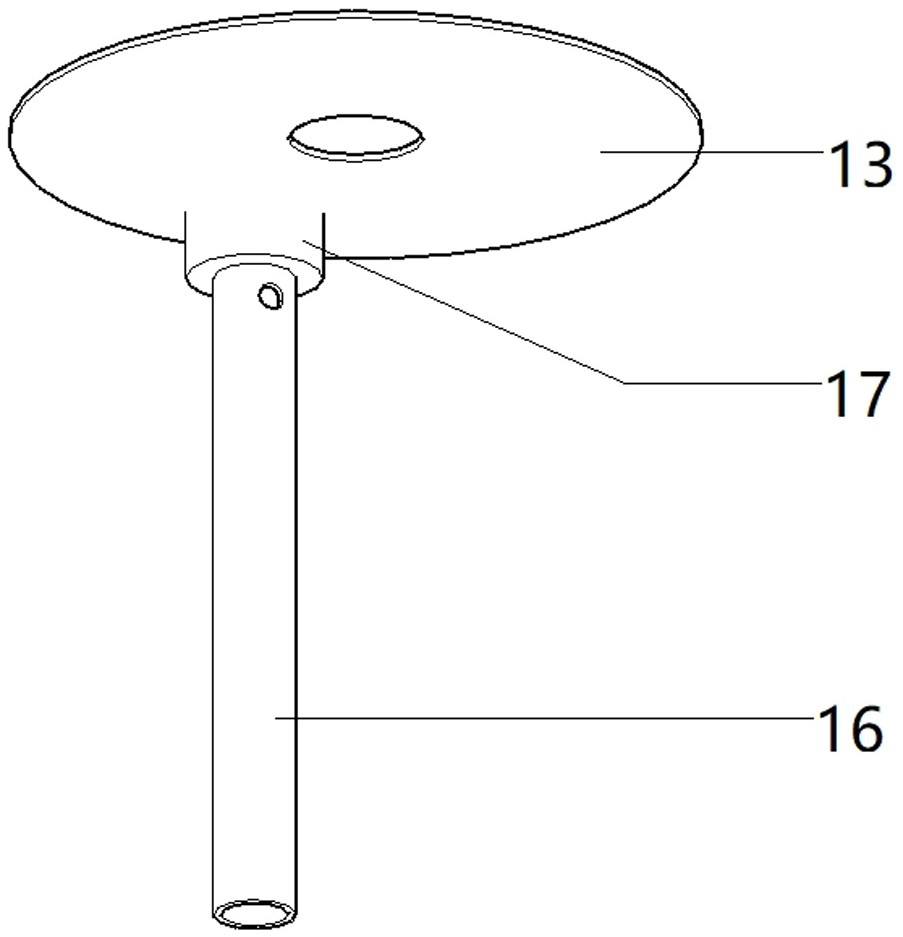

[0054] Embodiment 2. An automatic maintenance device for fan foundation concrete is composed of water storage system, power supply system 2, electric control system 3 and spray system 4. The water storage system 1 is composed of a water tank, a water tank bracket and a remote water level alarm. The water tank is composed of a box body 12 and a box cover 13. There is a water inlet on the box cover 13, and the box body 12 has a water outlet. The water tank bracket is composed of an upper ring, a lower ring, and a The box body support bar 18 is formed, is used for supporting the soft water tank, and the upper and lower rings can be split into several circular arcs, and the box body support bar 18 mounting holes are arranged on the upper and lower rings, and the water level remote alarm assembly consists of a float 14, a conduit 16. The pull wire 15 and the magnetic switch remote alarm 17 are installed under the water tank cover. When the water level drops to a certain height, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com