Emulsion matrix conveying system

A technology of latex matrix and conveying system, applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc., can solve the problems of metal parts falling, safety accidents, easily damaged processing devices, etc., and achieve improved cooling efficiency and convenience Effect of cleaning and improving cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with specific embodiments.

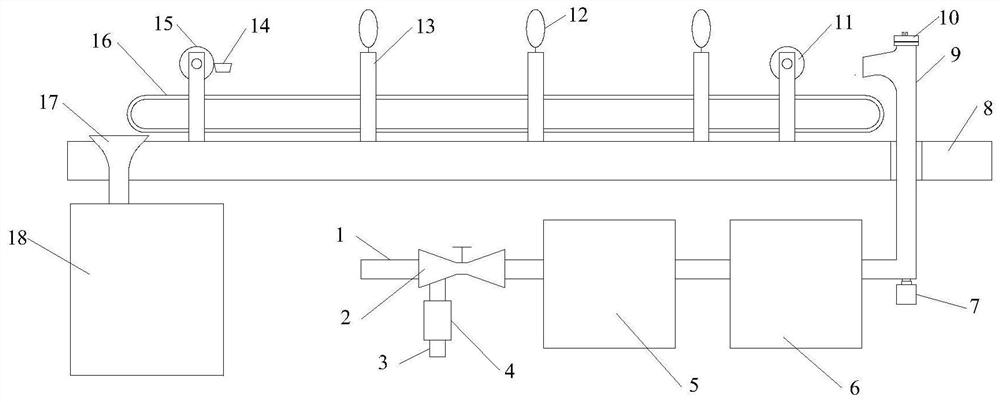

[0032] refer to Figure 1-7 , the latex matrix delivery system that the present invention proposes, comprises:

[0033] Conveyor belt 16, is used for conveying latex matrix;

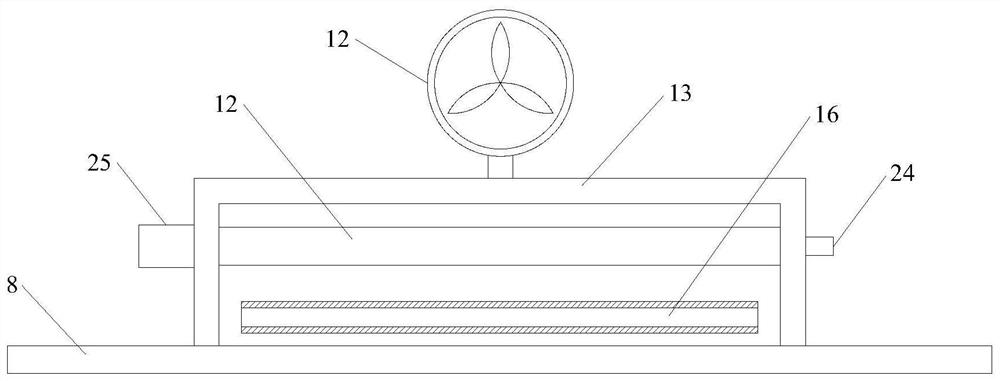

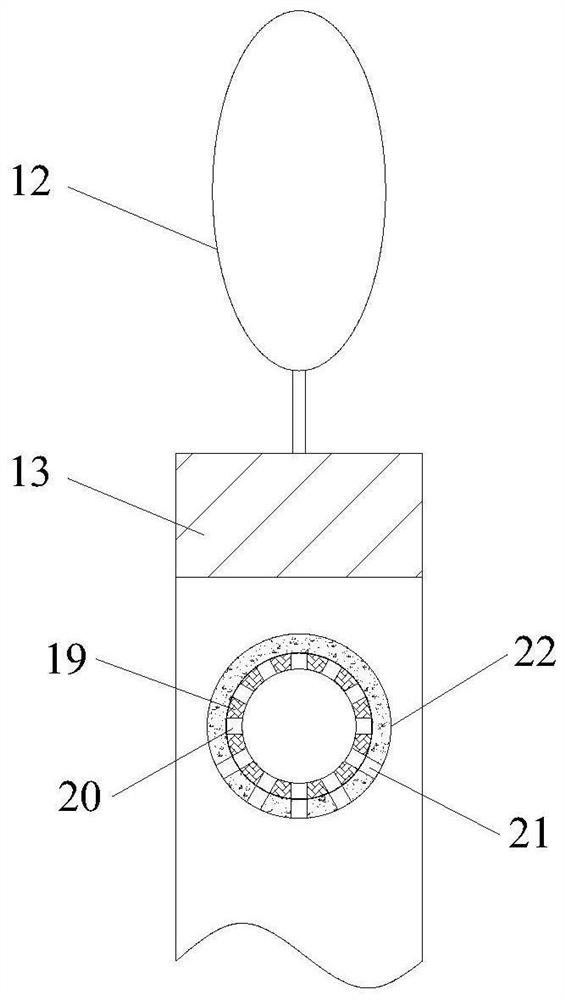

[0034] Several supports 13 are arranged on the top of the conveyor belt 16, and the support 13 positioned at the head end is provided with the first pressure roller 11, the support 13 positioned at the end is provided with the second pressure roller 15, and all the other supports 13 are provided with The air cooling device 12 and the spray assembly of the cooling latex matrix, the pressure of the spray assembly can be adjusted;

[0035] Vertical feeding pipe 9 can cool the latex matrix therein, and is used to transport the latex matrix to the conveyor belt 16;

[0036] Batching assembly, its discharge end is communicated with vertical feeding pipe 9, is used for preparing latex matrix;

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com