Workshop scrap iron recovery device

A recycling device and iron scrap technology, applied in metal processing equipment, maintenance and safety accessories, cleaning methods and appliances, etc., can solve problems such as waste of resources, low recovery rate, environmental pollution, etc., to improve recovery rate and reduce work Strength, work performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

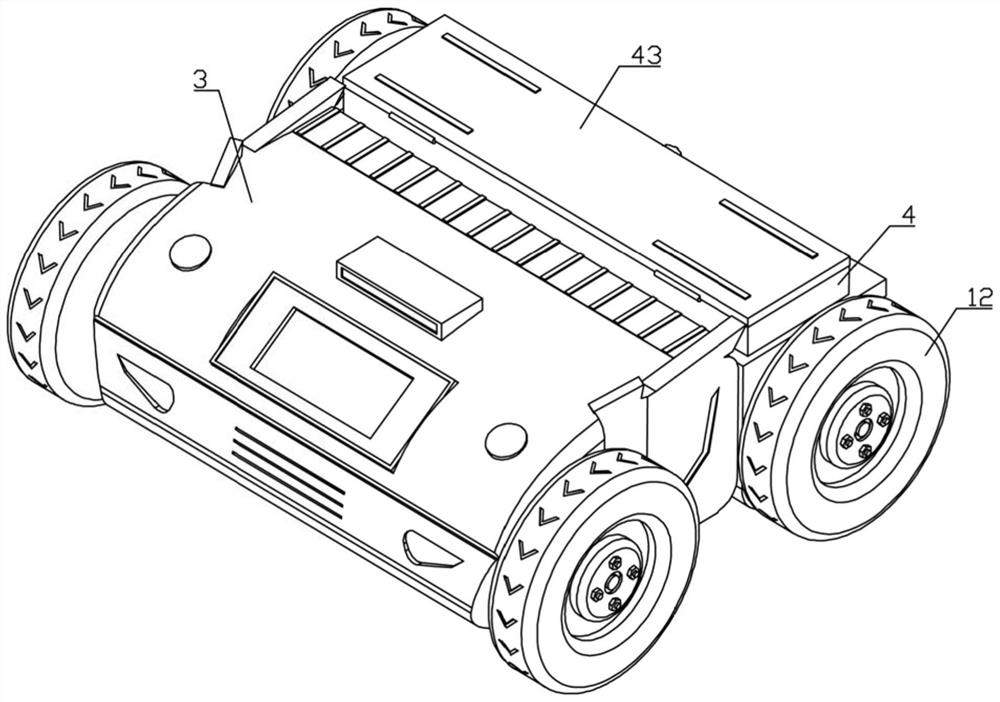

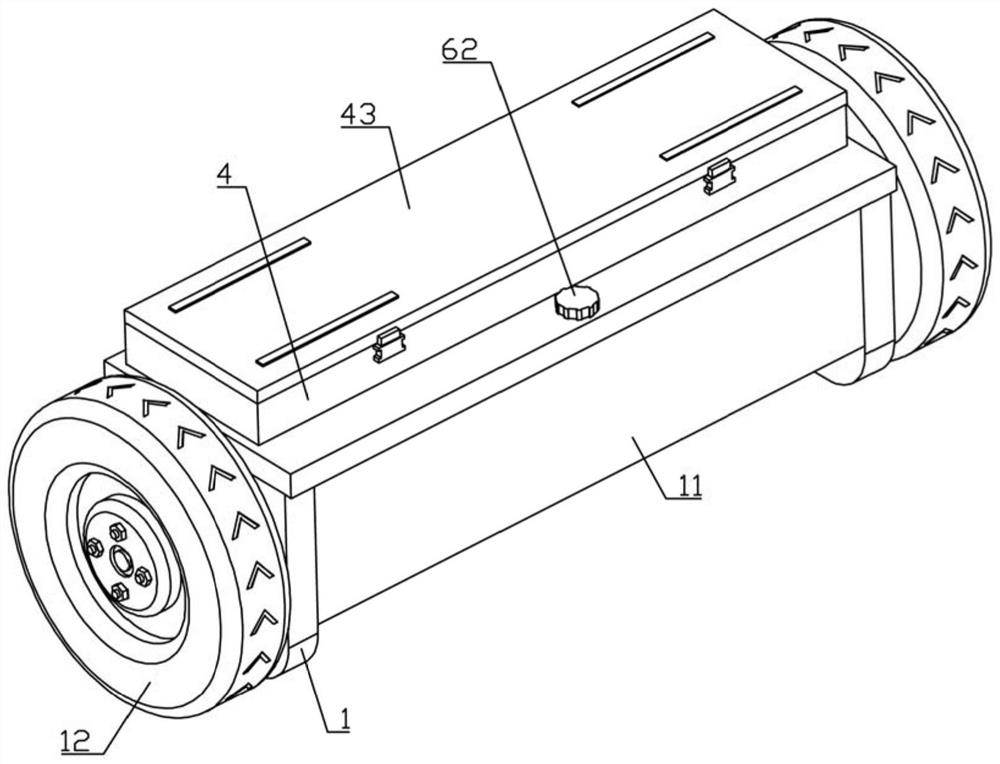

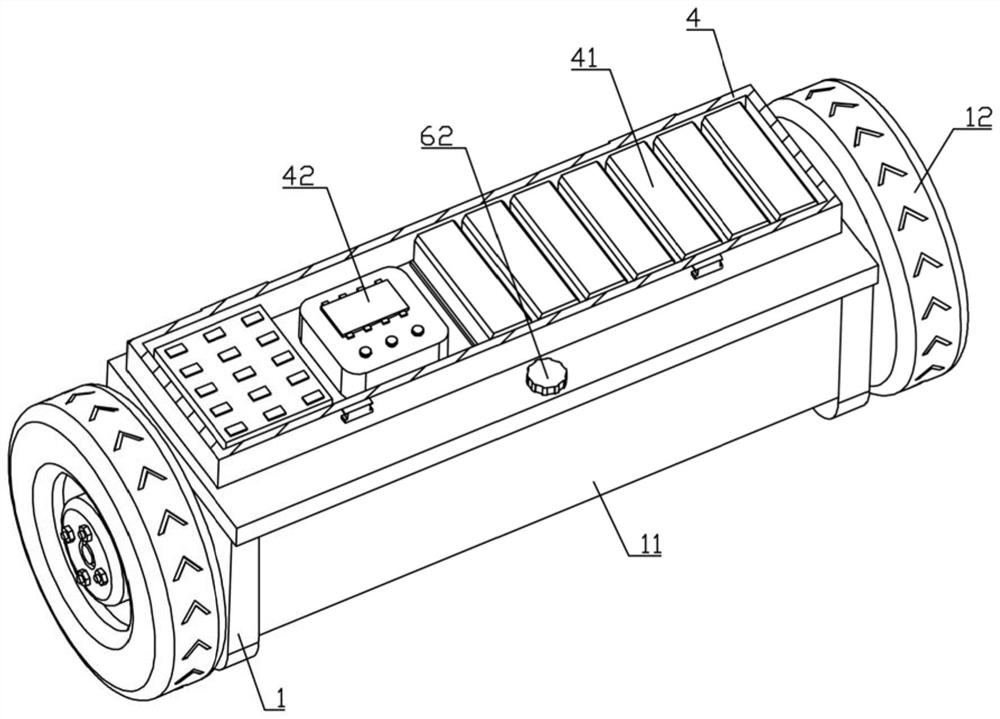

[0029] Such as Figure 1-12 As shown, a kind of workshop chip recycling device of the present invention includes a power mechanism and a collection mechanism. The collection mechanism includes two fixed plates 1, a C-shaped plate 11, two moving wheels 12, two discs 13, three Fixed rod 14, three arc-shaped baffle plates 15, three arc-shaped electromagnets 16, six top blocks 17 and two first fixed blocks 18, two fixed plates 1 are fixedly connected by C-shaped plate 11, C The shape plate 11 is connected with the power mechanism, and the two moving wheels 12 are assembled on the side away from the two fixed plates 1 through the rotation of the rotating shaft. The rotating shafts of 12 run through the two fixed plates 1 and are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com