Heat dissipation plate of BSG motor inverter and processing method

A BSG motor, heat sink technology, applied in electrical components, electrical equipment structural parts, cooling/ventilation/heating transformation, etc., can solve the problem of poor glue filling process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

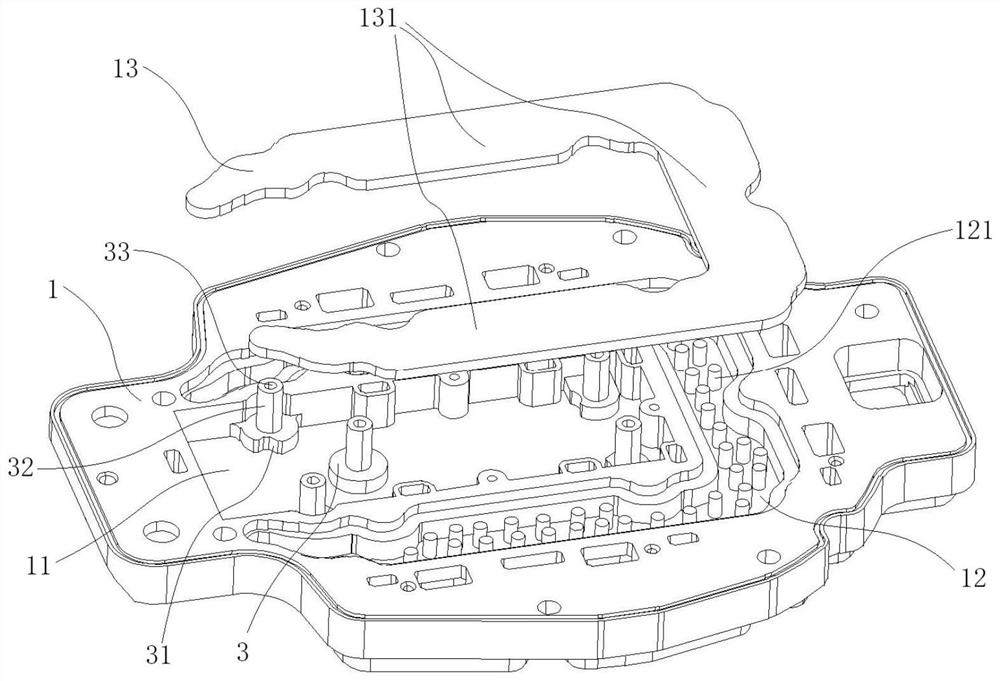

[0039] In this embodiment, the height of the positioning boss 3 of the capacitor module is 3.4 mm, which not only ensures the glue filling effect, but also does not affect the thickness of the cooling plate body or the space utilization rate of the inverter. The positioning boss 3 of the capacitor module is provided with an escape notch 31 for better matching with the capacitor module. The upper end surface of the positioning boss 3 of the capacitor module is provided with an internally threaded hole 33 for fixing with the capacitor module. The flatness of the welding area 131 of the power module is 0.4 mm to achieve a better welding effect.

[0040]Processing method: In this embodiment, the processing is divided into two components: the heat sink body and the cover plate 13. The cover plate 13 adopts a stamping process, and the heat sink body adopts a die-casting process. When die-casting the heat sink body, the spoiler part 121 and the spoiler part 121 are die-cast at the sa...

Embodiment 2

[0042] In this embodiment, the height of the positioning boss 3 of the capacitor module is 5mm, which not only ensures the glue filling effect, but also does not affect the thickness of the cooling plate body or the space utilization rate of the inverter. The U-shaped runner groove 12 is provided with a spoiler 121, and the spoiler 121 is fixed on the bottom of the U-shaped runner groove 12 by welding, which can enhance the disturbance effect of the cooling medium fluid, enhance the heat dissipation effect, and ensure the normal operation of the power module. The spoiler part 121 is a plate-shaped protrusion, and the spoiler part 121 is arranged in the direction of the U-shaped runner groove 12; the upper end surface of the capacitor module positioning boss 3 is provided with a capacitor module positioning column 32, and the capacitor module The upper end surface of the module positioning column 32 is provided with an internal thread hole 33, which is convenient for adapting an...

Embodiment 3

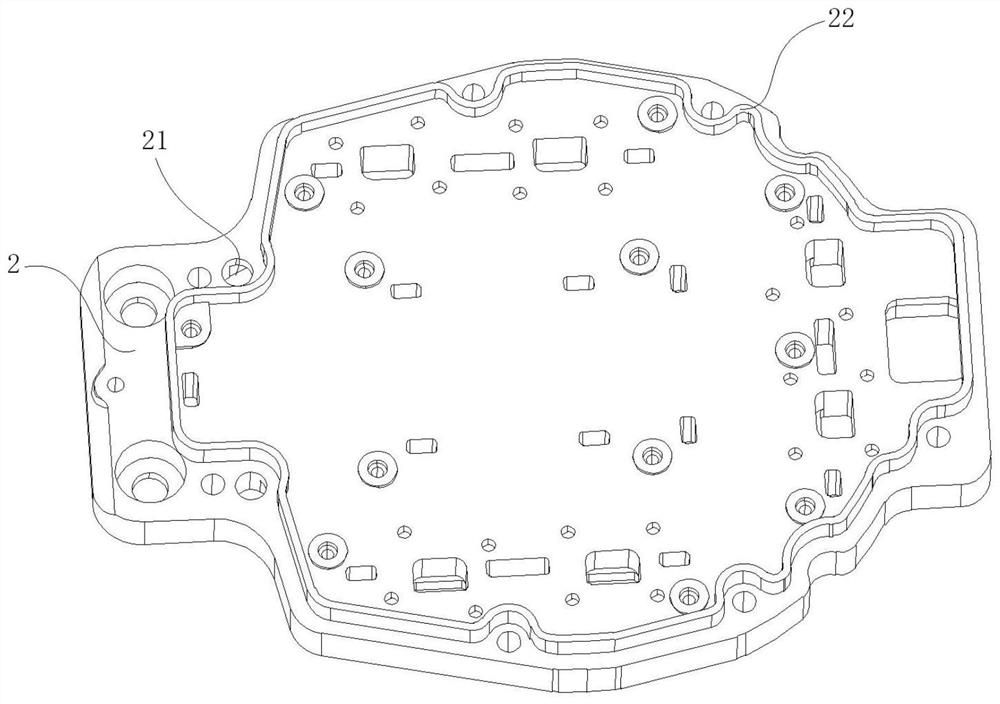

[0045] In this embodiment, the height of the positioning boss 3 of the capacitor module is 3.7mm, which not only ensures the glue filling effect, but also does not affect the thickness of the cooling plate body or the space utilization rate of the inverter. The assembly surface 2 is provided with a PCB installation limit wall 22 in a closed loop along the end surface contour, which can effectively realize the installation and positioning of the PCB module, and facilitate the protection of the PCB module by filling glue. The surface electroplating treatment is nickel plating, which is used to improve the weldability between the heat sink body and the power module and the overall corrosion resistance of the heat sink body. The flatness of the welding area 131 of the power module is 0.25 mm to achieve better welding effect.

[0046] Processing method: The difference between this embodiment and the above-mentioned embodiment is that the corrugated heat dissipation ribs are stamped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com