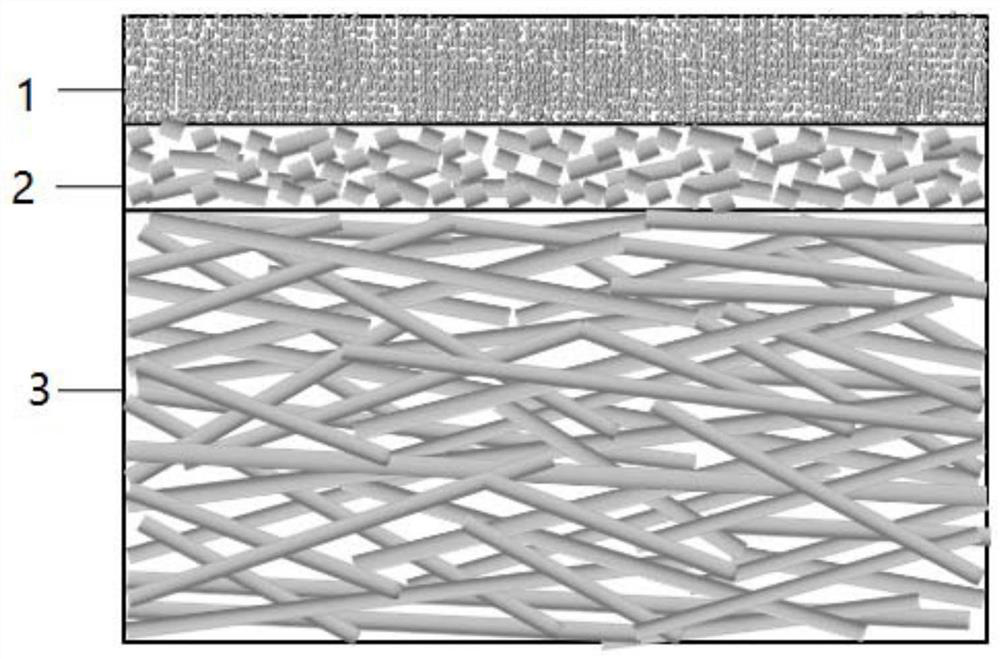

Gas diffusion layer with double-microporous layer structure and preparation method thereof

A technology of gas diffusion layer and microporous layer, applied in the direction of fuel cells, structural parts, electrical components, etc. Material particle size selection space is limited and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

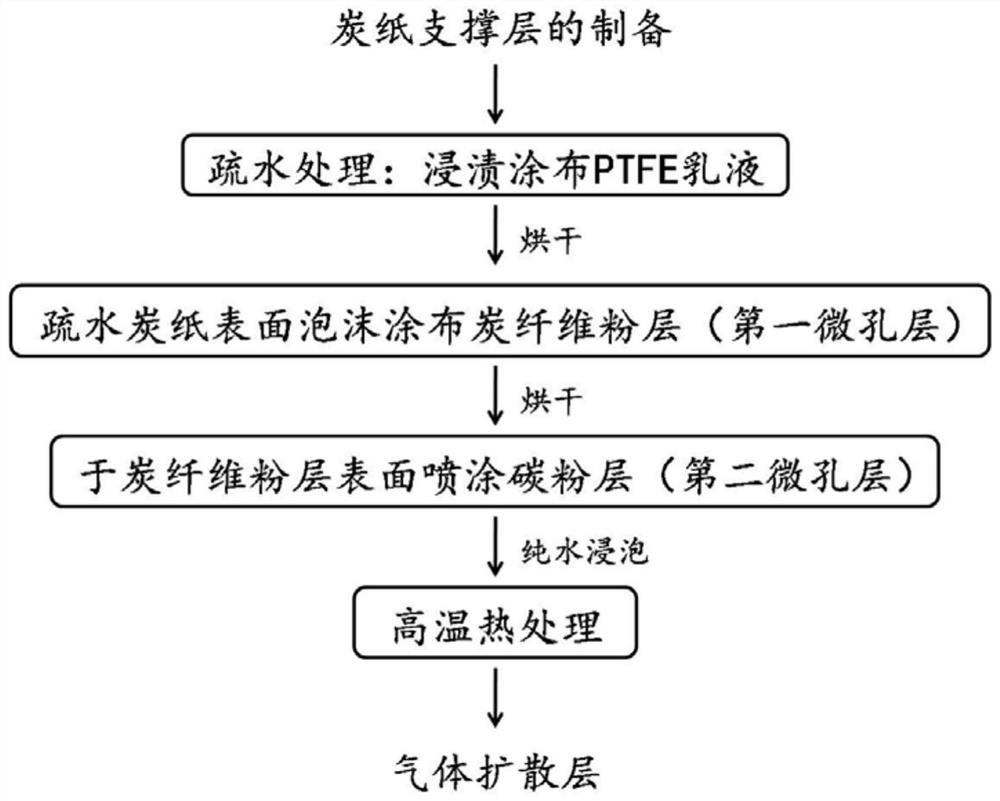

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of carbon paper support layer

[0064] Firstly, the carbon paper base paper is prepared by the wet papermaking process, and the basis weight is 43±5g / m 2 ; Secondly, the base paper is dipped and coated with thermosetting phenolic resin, and the coating weight is 1 times that of the base paper; again, the hot-pressing treatment is carried out, the hot-pressing pressure is 5MPa, the hot-pressing temperature is 180°C, and the hot-pressing time is 20min; finally, the The base material is carbonized and graphitized, the carbonization temperature is 1200°C, the carbonization time is 1h, the graphitization temperature is 2200°C, the graphitization time is 1h, and finally the carbon paper product as the support layer is obtained.

[0065] (2) Preparation of slurry

[0066] A. Preparation of carbon paper hydrophobic treatment slurry: take 60wt% aqueous polytetrafluoroethylene (PTFE) emulsion, add deionized water to dilute to 10wt% PTFE mass fraction, stir evenly...

Embodiment 2

[0080] (2) Preparation of slurry

[0081]B. Prepare the coating slurry for the first microporous layer: mix carbon fiber powder, sodium carboxymethyl cellulose, benzenesulfonyl hydrazide foaming agent, and deionized water in a ratio of 15:2:3:80 for later use, and then Transport to the foam slurry storage device for standby, and maintain a low-speed stirring state to ensure good distribution of carbon fiber powder in the foam, the concentration of the slurry is 15wt%.

[0082] Other steps are identical with embodiment 1.

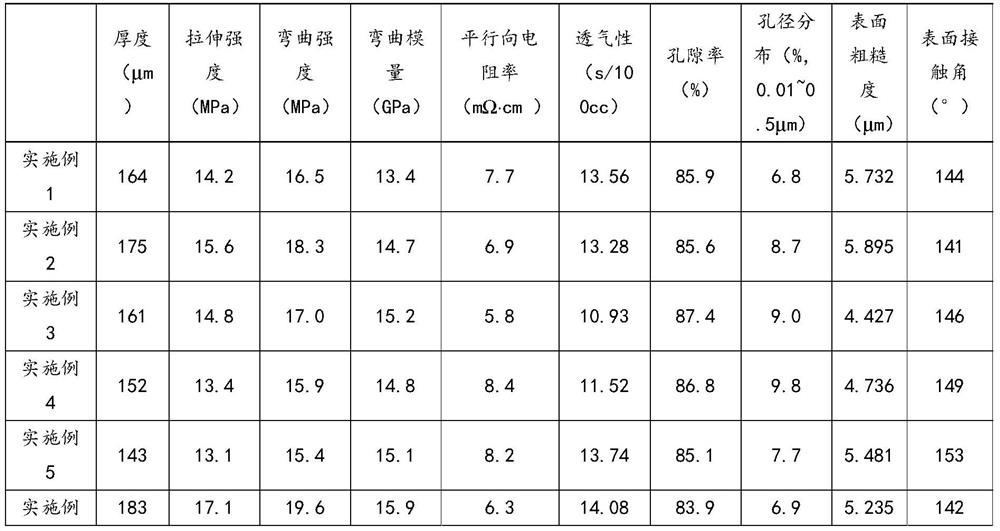

[0083] The performance parameters of the final gas diffusion layer product are shown in Table 1.

Embodiment 3

[0085] (2) Preparation of slurry

[0086] C. Preparation of the second microporous layer coating slurry: first, ethanol, isopropanol and water are mixed uniformly in a ratio of 4:4:2; then, weigh carbon powder (Cabot, VXC-72R) and add ethanol / In the mixed solvent of isopropanol / water, the ratio of carbon powder to mixed solvent is 1:9, and the concentration of carbon powder is 10wt%. Use a double planetary mixer to stir at a low speed of 300rpm at room temperature until the carbon powder is completely covered with alcohol. After the solution is wrapped, carry out high-speed shear dispersion at a speed of 1500rpm, and finally fully mix the carbon powder and the solvent to obtain a continuous and uninterrupted uniform black oily liquid; then add 10wt% sodium chloride aqueous solution, and the amount added is 100% of the carbon powder. 3wt%, medium speed (800rpm) and stir evenly; finally, weigh 10wt% PTFE suspension with 43wt% of the amount of carbon powder (according to solute)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com