Preparation method of layered double hydroxide composite material for positive electrode of lithium-sulfur battery

A hydroxide, composite material technology, applied in battery electrodes, lithium batteries, positive electrodes, etc., can solve the problem of rare polar metal compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The layered dual hydroxide composite preparation method for the positive electrode of lithium sulfur batteries, including the following steps:

[0023] (1) Synthesis ac-feconi: First, 190.1 mgnicl 2 · 6h 2 O and 25.4mgfecl 2 Dissolved in 20 ml of methanol to give methanol solution A, spare; 50 mgZiF-67 ultrasonic dispersed in 10 ml of methanol to obtain methanol solution B; then pour methanol solution A in methanol solution B to give a mixed solution; finally mixed The solution was transferred to the autoclave at 120 ° C for 1 h, centrifugally, and washed with methanol to remove residual ions, and dried for 12 hours;

[0024] (2) Synthesis of Cu Sas / Ac-Feconi: 40 mgac-feconi (amorphous / crystalline FECONI LDH hollow nano box) obtained by step (1) is dispersed in a 20 ml of methanol / ammonium hydroxide mixture to obtain an Ac-Feconi solution. Among them, according to methanol in mass: ammonium hydroxide is 3: 1; 1.0 mgcucl 2 . Hide 2 O Dissolve in 5 ml of methanol to get...

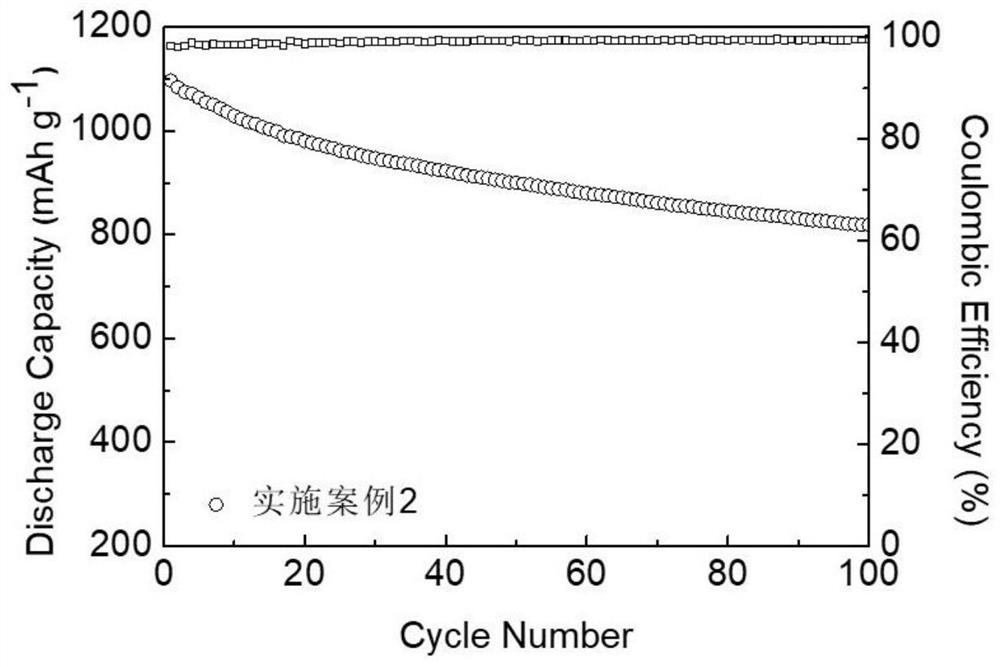

Embodiment 2

[0026] The step (2) synthesis Cu Sas / Ac-FeConi will be Cucl under the continuous stirring conditions at room temperature 2 The methanol solution was added dropwise to the Ac-FeConi solution, and the mixture was obtained for 50 minutes at room temperature.

[0027] Others are the same as in Example 1.

Embodiment 3

[0029] The layered dual hydroxide composite preparation method for the positive electrode of lithium sulfur batteries, including the following steps:

[0030](1) Synthesis ac-feconi: First, 383MGNICL 2 · 6h 2 O and 50.9mgfecl 2 Dissolved in 40 ml of methanol to give a methanol solution A, spare; a mixture of 100 mgziF-67 is dispersed in 20 ml of methanol to obtain a methanol solution B; then pour the methanol solution A in methanol solution B to obtain a mixed solution; finally mixed The solution was transferred to the autoclave at 120 ° C for 1 h, centrifugally, and washed with methanol to remove residual ions, and dried for 12 hours;

[0031] (2) Synthesis of Cu Sas / Ac-Feconi: 80 mgac-feconi obtained by step (1) is dispersed in a 40 ml of methanol / ammonium hydroxide mixture to obtain an Ac-Feconi solution, wherein the mass ratio of methanol: ammonium hydroxide is 3: 1 ; 2.0mgcucl 2 . Hide 2 O Dissolve in 10 ml of methanol to get Cucl 2 Methanol solution; Cucl Cucl under cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com