Ddeformation detection method and device for groove type solar heat collecting tube

A trough-type solar energy and detection device technology, which is applied in the direction of solar collectors, solar collector safety, solar thermal energy, etc., can solve problems such as many errors, troublesome installation, and many transformation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

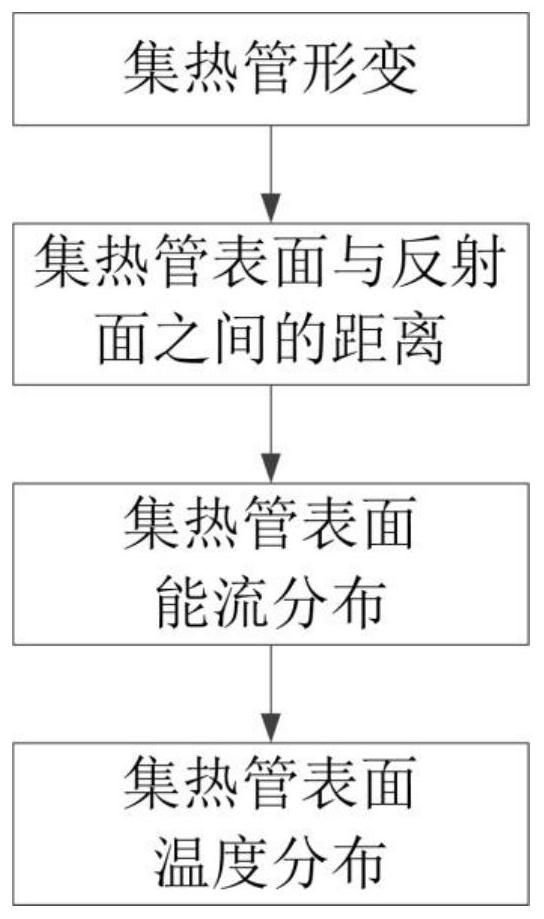

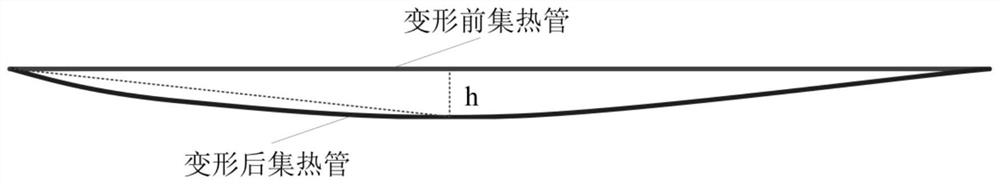

[0044] Embodiment 1: as attached Figure 1-3 Shown, described in the present invention is a kind of trough type solar collector tube deformation detection method, comprises steps:

[0045] S1: Use the sun angle detector to measure the real-time sun altitude angle at the trough condenser, and adjust the shooting angle of the infrared thermal imager to the corresponding angle;

[0046] S2: Move the infrared thermal imager to the center of the trough condenser, and shoot the heat collecting tube forward;

[0047] S3: Adjust the infrared thermal imager to the set position, take pictures and detect multiple points on a heat collecting tube, and express the temperature distribution of different points on the surface of the heat collecting tube as N 1 ~N n ;

[0048] S4: Compare N respectively 1to N n value, when N 1 to N n When all are the same, it indicates that the heat collecting tube is not deformed;

[0049] If N 1 to N n not the same when N 1 to N n Gradually incre...

Embodiment 2

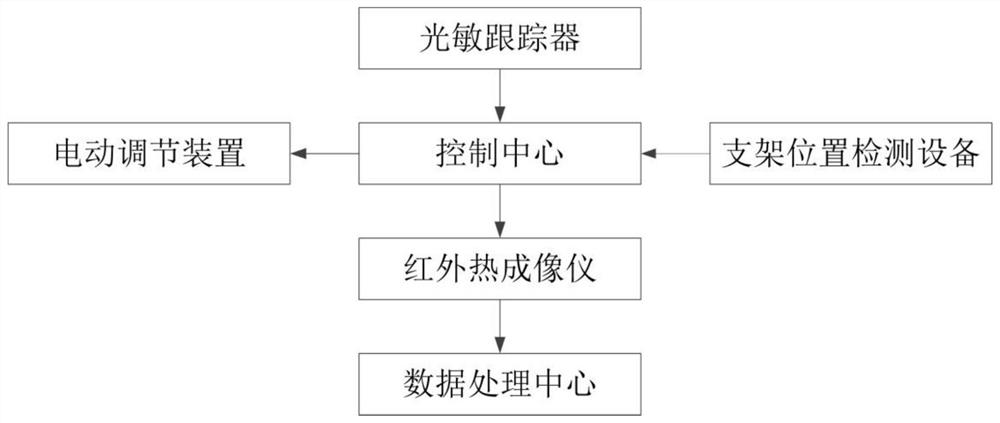

[0055] Embodiment 2: as attached Figure 4-8 Shown, described in the present invention is a kind of trough solar collector tube deformation detection device, comprising:

[0056] Detection platform 1, described detection platform 1 is provided with infrared thermal imager 11, the first linear motion mechanism 12 for adjusting the position of infrared thermal imager 11; Preferably, in order to avoid the error that causes due to time, described The number of infrared thermal imagers 11 is multiple, and each of the infrared thermal imagers 11 corresponds to a first linear motion mechanism 12, and multiple infrared thermal imagers 11 simultaneously shoot multiple points of a heat collecting tube Detection can avoid errors caused by time.

[0057] A mobile control platform, the mobile control platform is used to adjust the position of the detection station 1;

[0058] Detection platform position detection device 3, the detection platform position detection device 3 is used to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com