Automobile steering wheel vibration absorber

A steering wheel and vibration absorber technology, which is applied to the steering control, steering mechanism, and steering rods installed on the vehicle, and can solve the problems of harmful substances, reduced durability of dynamic vibration absorbers, and large-scale changes in structure and size. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

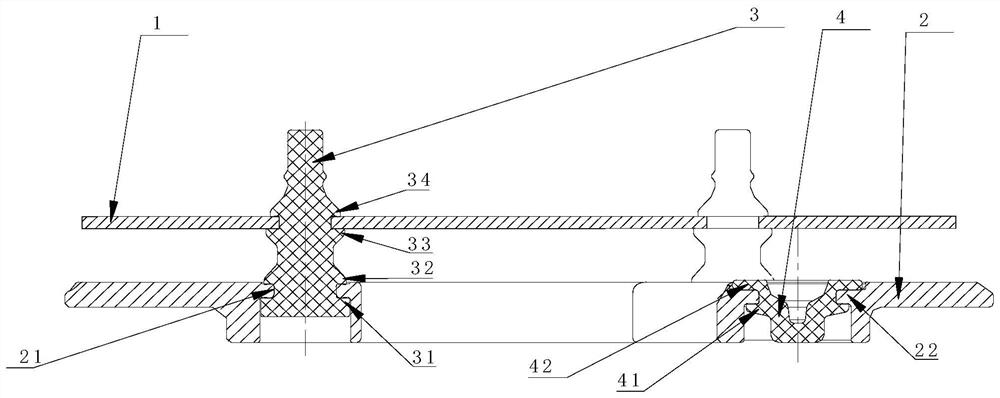

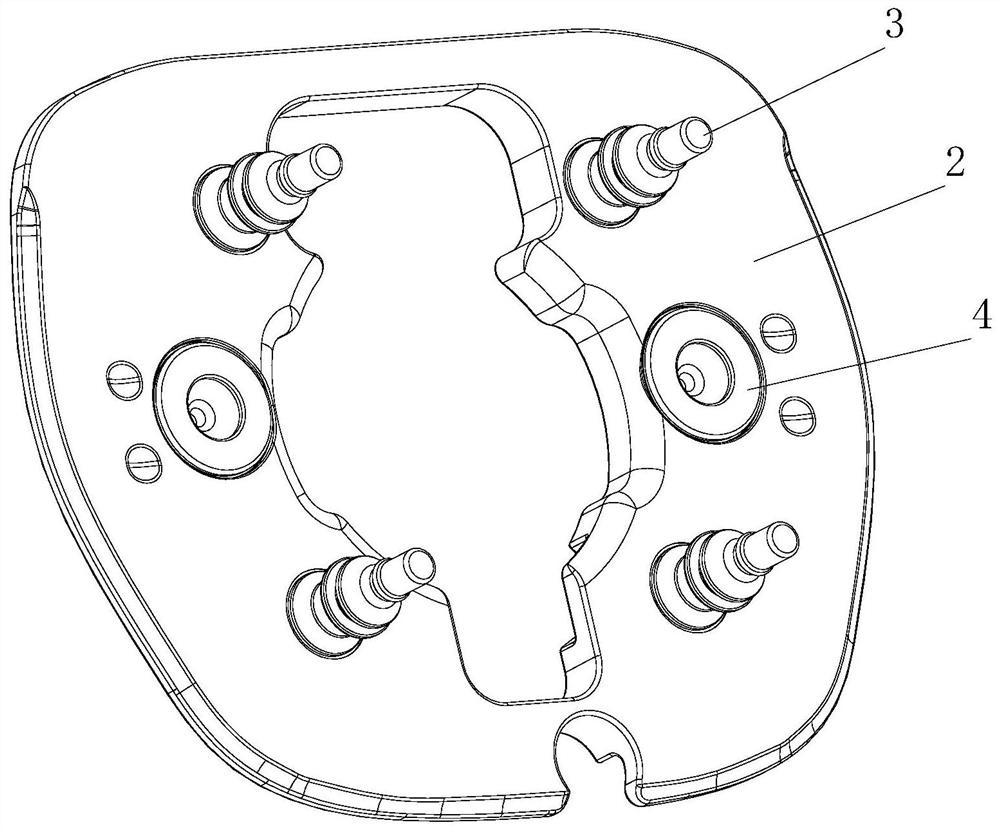

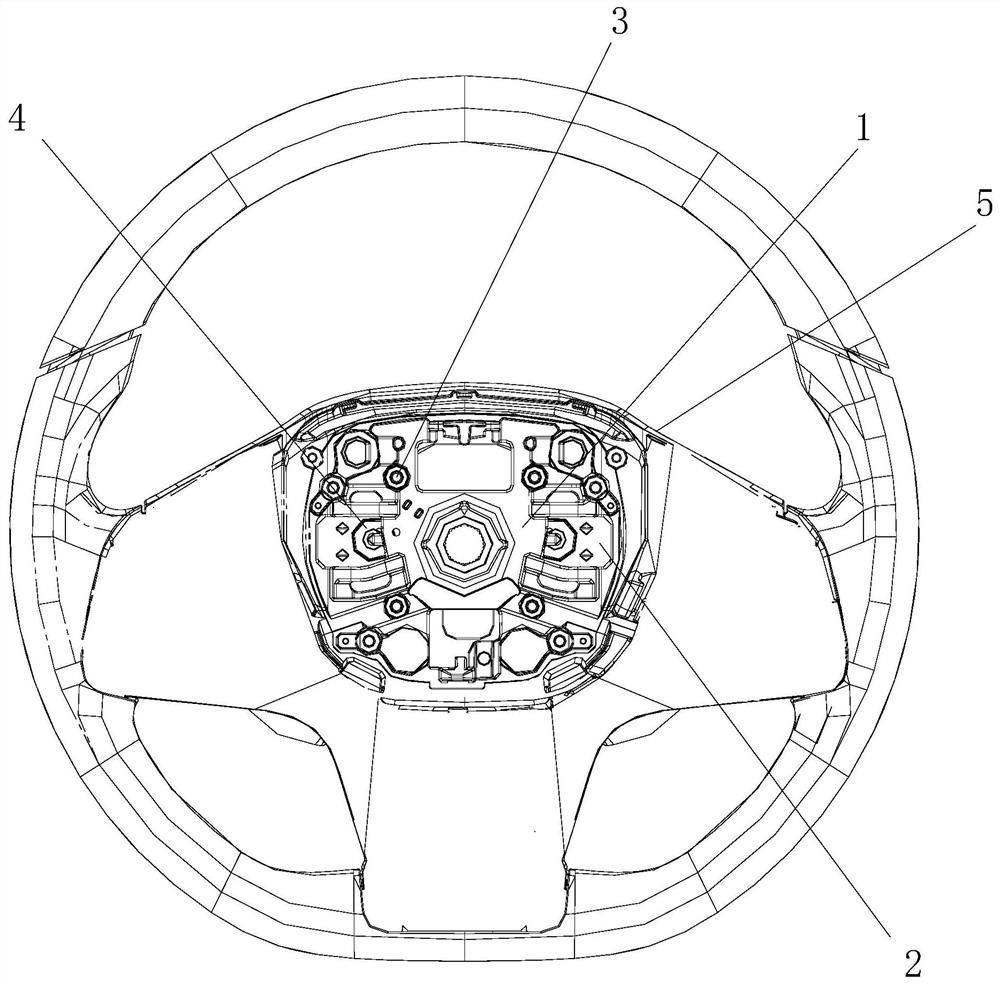

[0017] refer to Figure 1-Figure 3 , the present invention proposes an automobile steering wheel vibration absorber, which includes a steering wheel metal frame 1 and a mass block 2, the mass block 2 is arranged on one side of the steering wheel metal frame 1, and four rubber damping legs 3 are connected to the mass block 2 and four A rubber damping leg 3 is distributed in a square shape, and a plurality of rubber damping legs 3 run through the metal frame 1 of the steering wheel and are connected with the metal frame 1 of the steering wheel.

[0018] In this embodiment, the metal frame 1 of the steering wheel and the mass block 2 are connected by quickly installing the rubber damping legs 3. This connection method is relatively novel, and the development difficulty is low, the cost is low, and the development time is short.

[0019] In this embodiment, the mass block 2 is provided with a plurality of first through holes, and one end of a plurality of rubber damping legs 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com