PDC bit capable of achieving salvaging while drilling

A diamond bit and drilling-while-drilling technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc., can solve the problems of high cost of diamond composite sheet and inability to solve the working efficiency of diamond composite sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

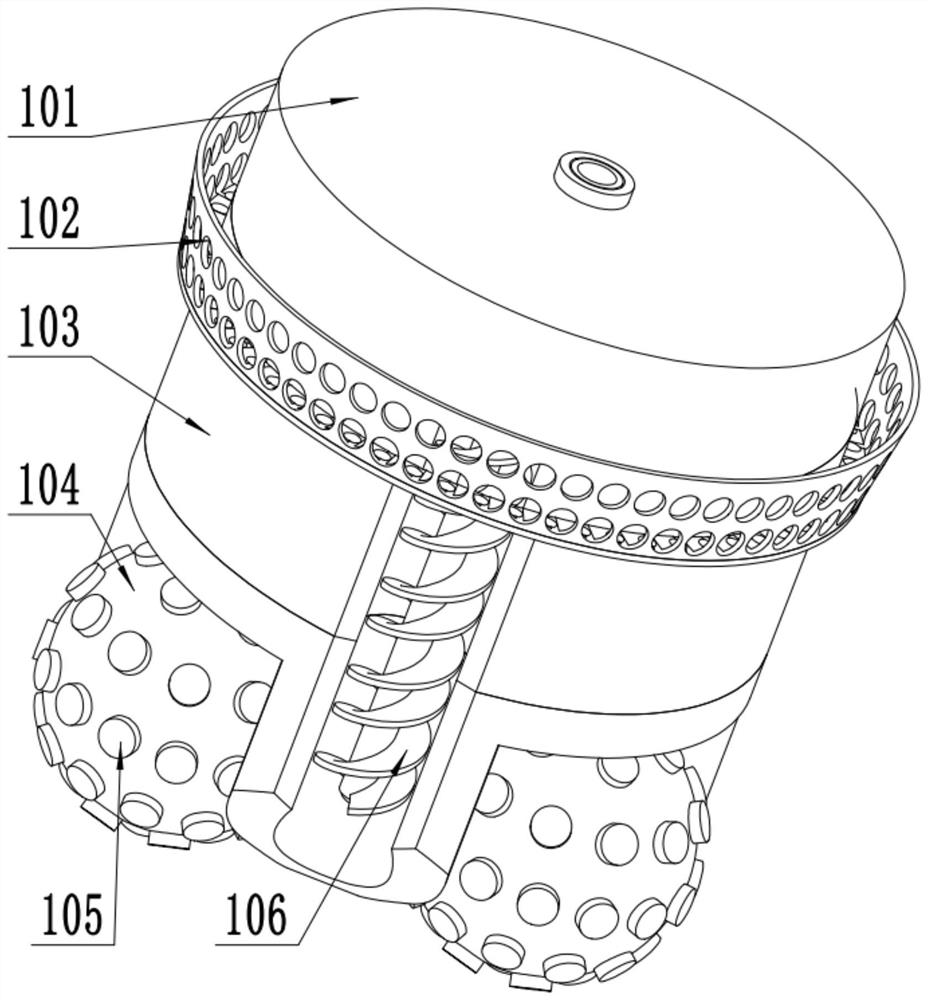

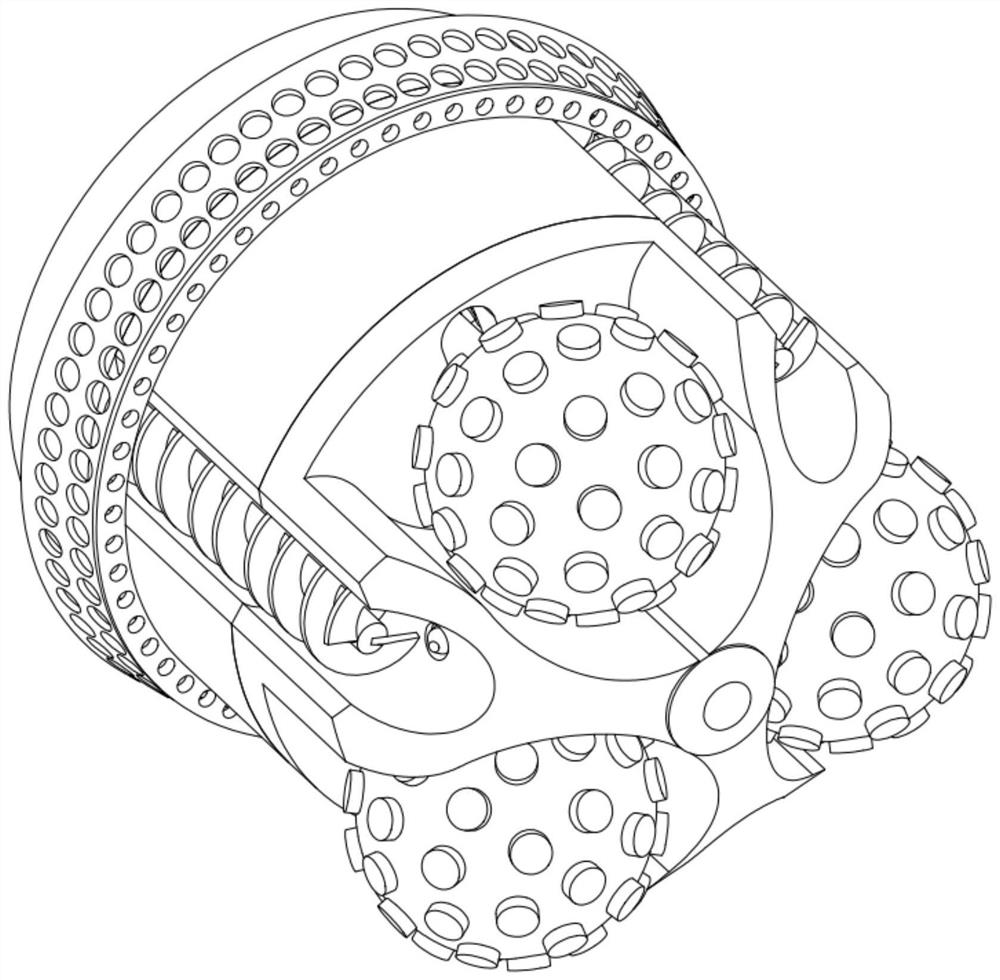

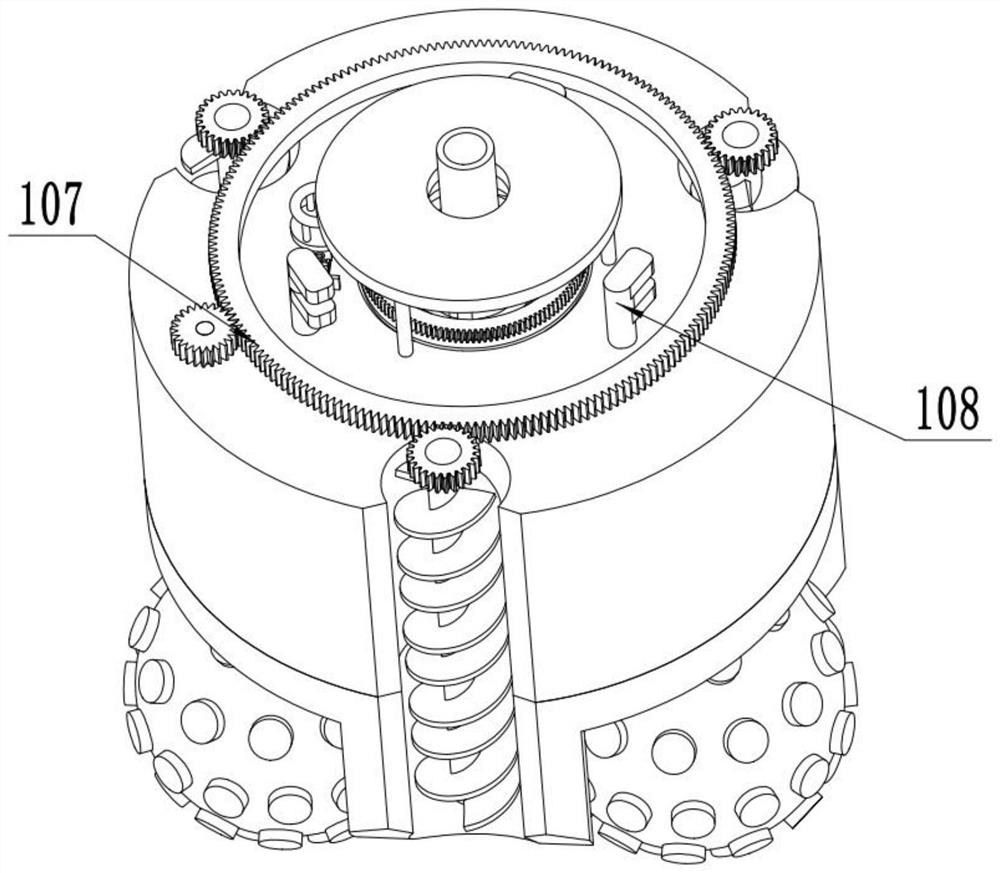

[0027] EXAMPLES: A drilling PDC diamond drill bit, including the base 135, and the casing 103 is attached to the base 135, and the casing 103 is fixedly mounted, and the salvage tank 102 is provided, and several drain holes are provided on the salvage groove 102. The housing 103 is fixedly mounted, and the upper cover 101 is attached, and the housing 103 is distributed across three winch 106, and the winch 106 is rotated to the housing 103 by the winch driving device 107, and the winch drive device 107 includes coaxial fixation. The drive gear 109 on the winch 106, and the drive gear 109 are driven from the motion of the ring gear 112 to rotate from the moving outer ring gear 112 to the housing 103, and the gear coordination is formed from the moving outer ring gear 110 and the active gear 110. The active gear 110 is rotatably mounted on the housing 103, and the active gear 110 is fixed to the output shaft of the motor 111, and the motor 111 is fixedly mounted inside the housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com