A textile mill reed transfer vehicle

A technology for textile mills and transfer vehicles, which is applied in the field of reed transfer devices for textiles, can solve the problems of broken, skewed, and loose reed teeth, and has the effect of facilitating movement and fixing and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

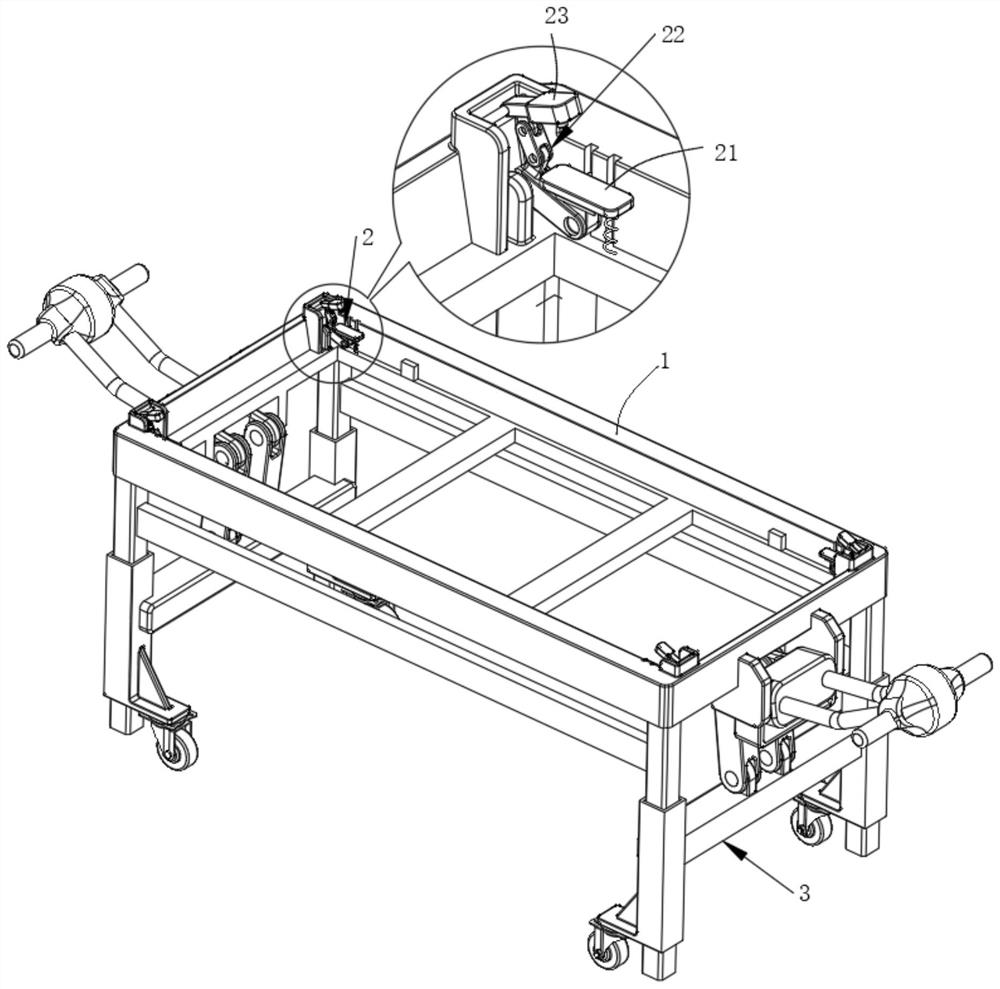

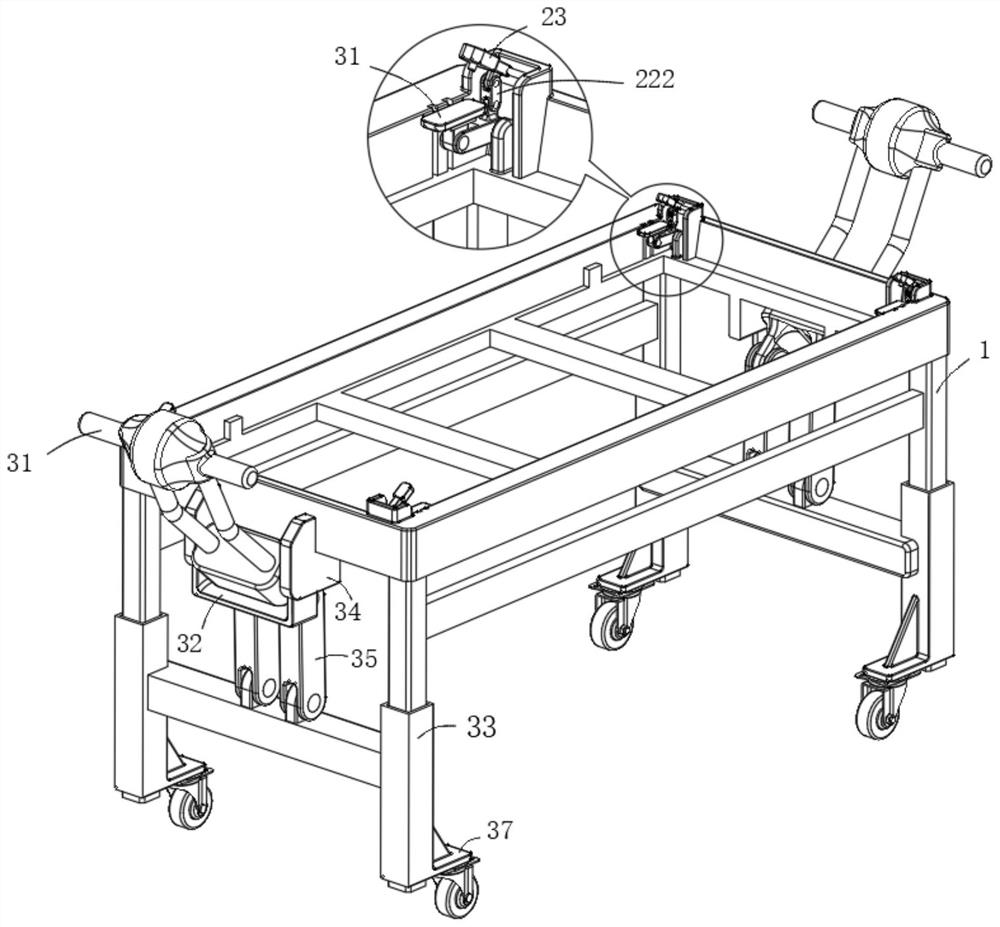

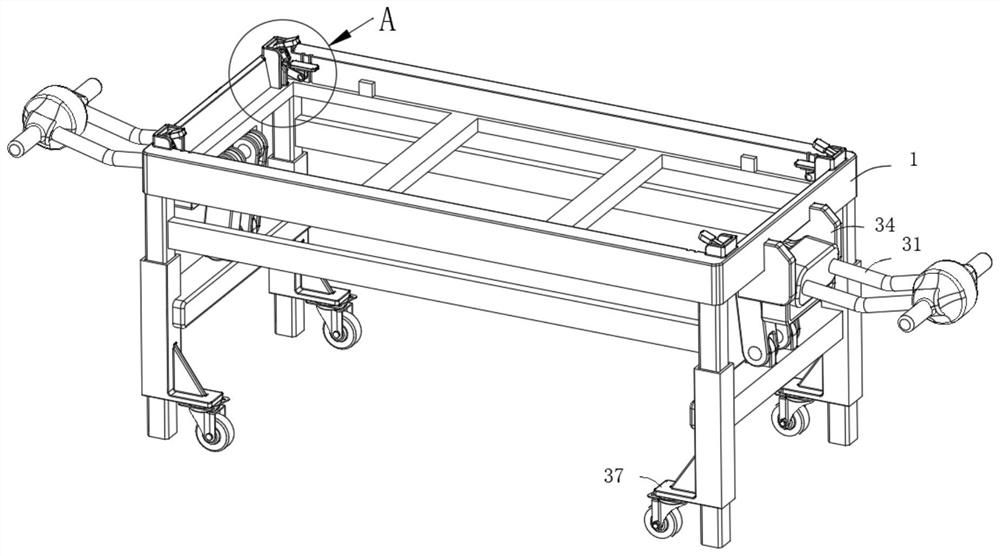

[0027] see figure 1 6, a reed transfer vehicle of a textile factory, comprising a frame body 1 and a reed body, and also comprising a buffer mechanism 2 arranged at the inner four corners of the top of the frame body 1, and the buffer mechanism 2 includes a steel for supporting The supporting plate 21 of the reed body, the connecting rod assembly 22 and the rotating part 23 for fixing the steel reed body, the connecting rod assembly 22 is driven by the supporting plate 21 to make the plug part on the outer wall of the rotating part 23 It is inserted into the gap between the reed teeth of the reed body to keep the reed body and the frame body 1 fixed.

[0028] The buffer mechanism 2 arranged at the inner four corners of the top of the frame body 1 can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com