Vertical high-dryness high-pressure squeezer

A high-dryness, high-pressure technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve problems such as restricting development, high maintenance costs, and material winding and jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

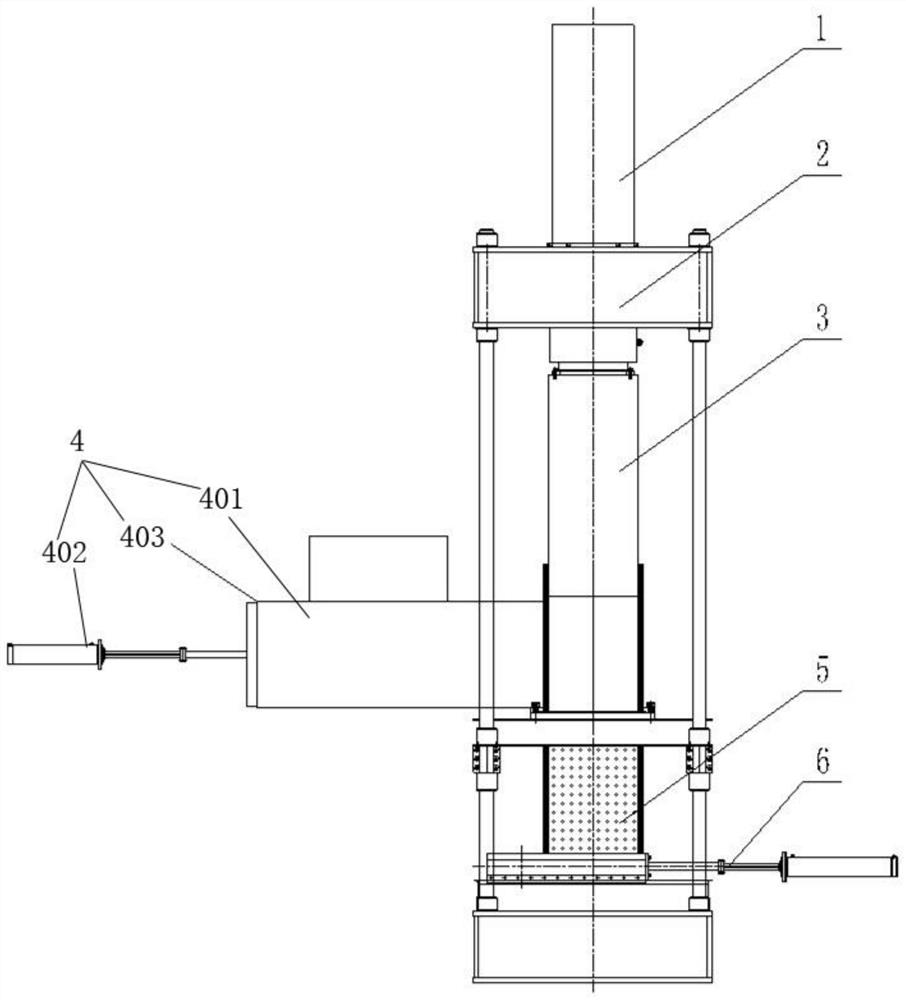

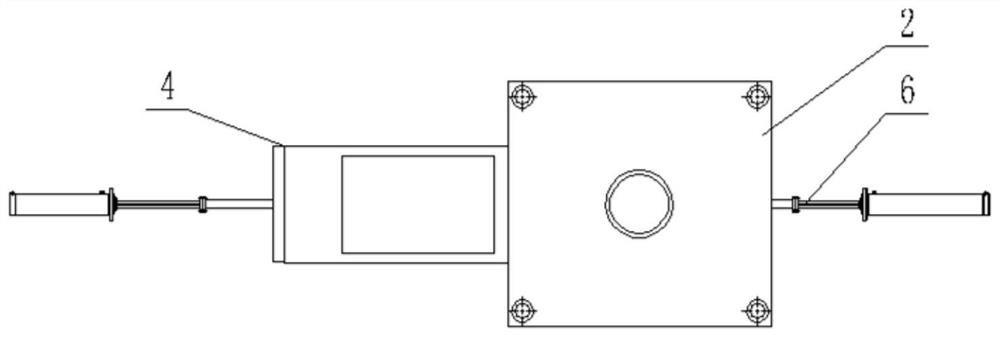

[0032] like figure 1 and figure 2 As shown, the vertical high-dryness high-pressure press machine provided by the present invention includes a press hydraulic system 1, a support frame 2, a pressure head 3, a porous separation cylinder 5, and a hydraulic slide valve 6; the press hydraulic system 1 is fixed on the support frame 2, the lower end of the press hydraulic system 1 is connected to the pressure head 3; the press head 3 extends into the porous separation cylinder 5, and reciprocates under the drive of the press hydraulic system 1; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com