Foamed asphalt foaming effect evaluation and foaming parameter optimization method

A technology of foamed asphalt and foaming parameters, which is applied in the field of evaluation of foaming effect of foamed asphalt and optimization of foaming parameters, and can solve problems such as difficult operation and easy deviation in calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Carry out foaming test on asphalt A, the foaming conditions are asphalt temperature 140°C, 150°C, 160°C, foaming water consumption 1%, 2%, 3%, 4%. The measured test result data are as follows.

[0031] Table 1 Asphalt foaming test results

[0032]

[0033] According to the requirements of expansion rate ≥ 10 times and half-life period ≥ 8s, the parameter range of foamed asphalt is initially selected. After screening, the foaming parameter conditions for primary selection are ①140°C, 3%; ②150°C, 2%; ③150°C, 3%; ④160 °C, 2%.

[0034] Under the four primary foaming conditions, mix the foamed asphalt and the milling material RAI, take 2kg of the mixture, spread it on a stainless steel plate with the same shape and size, and place it in an oven at 60°C. After drying for 6-8 hours, carry out image acquisition;

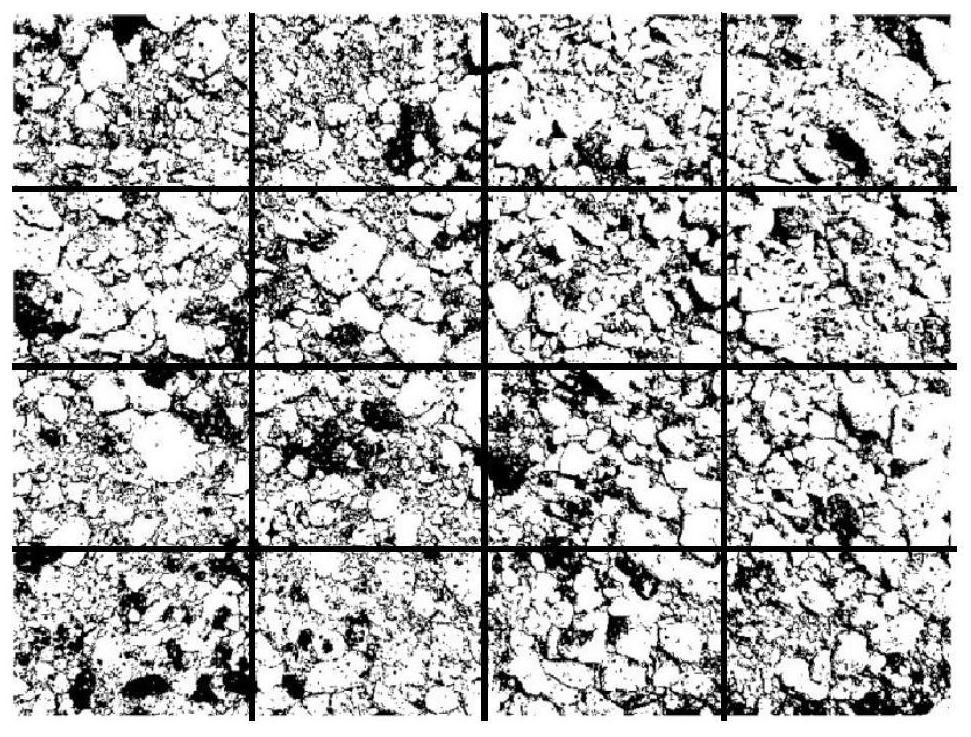

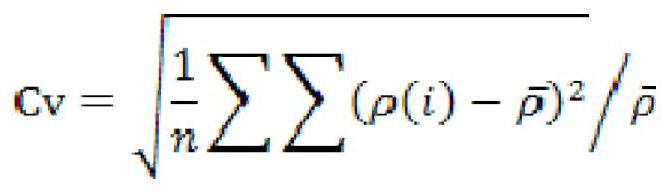

[0035] Digital image processing technology is used to process and analyze the image, and 4×4 grid division is selected. After image processing, the asphalt dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com