Method for controlling pure shear strain of high-speed impact load

A high-speed impact and pure shearing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of uncontrollable strain of the material being tested

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings.

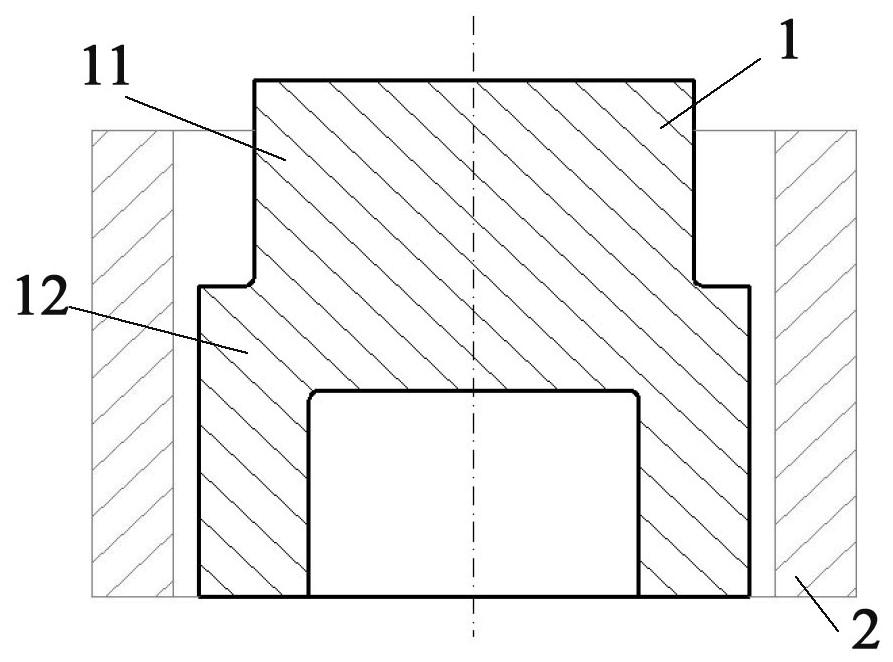

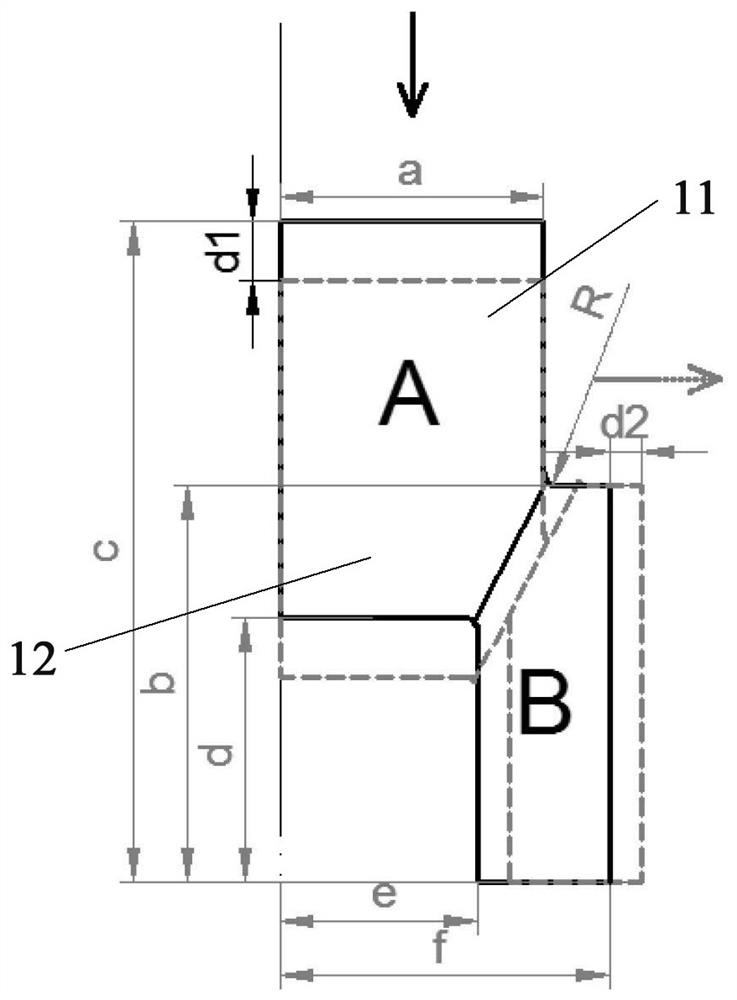

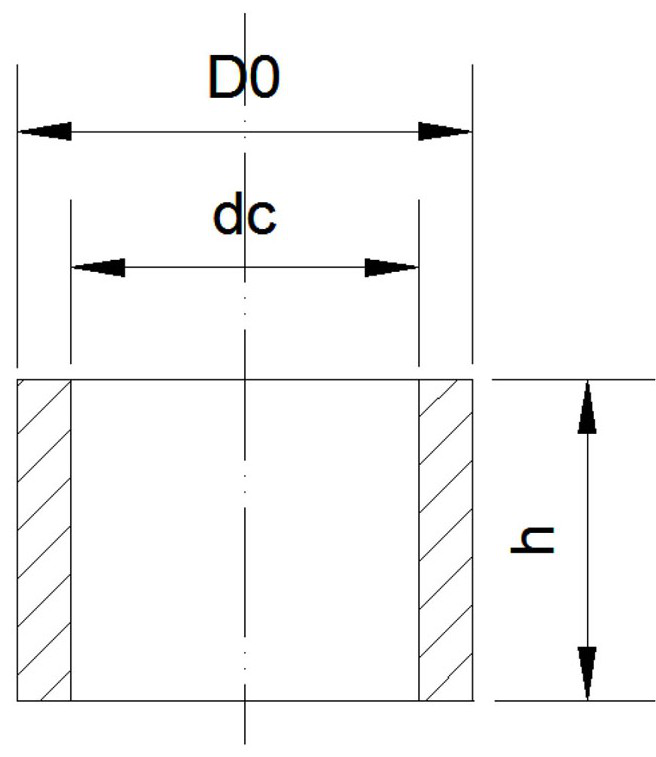

[0033] The invention provides a method for controlling pure shear strain of high-speed impact load, which is applied in the process of high-speed impact to obtain predetermined pure shear strain. The method uses a high-speed impact test loading device for loading impact load and performing impact compression; the present invention is based on a Hopkinson compression bar test device, and introduces a sample device, namely a cap-shaped sample 1 and an annular pressure-bearing device 2 . The cap-shaped sample 1 provides a geometric characteristic for obtaining a pure shear state; the annular pressure-bearing device 2 bears the load after the sample reaches the set strain, effectively limiting the continuous compressive loading of the sample by subsequent loading pulses , the combination of the two achieves effective control of pure shear strain.

[0034] A method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com