Comprehensive test bed system of exhaust gas turbocharger

A comprehensive test bench and exhaust gas turbine technology, applied in the field of exhaust gas turbocharger test bench, can solve the problems of poor economy, carbon black pollution, uneven temperature of turbine inlet interface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

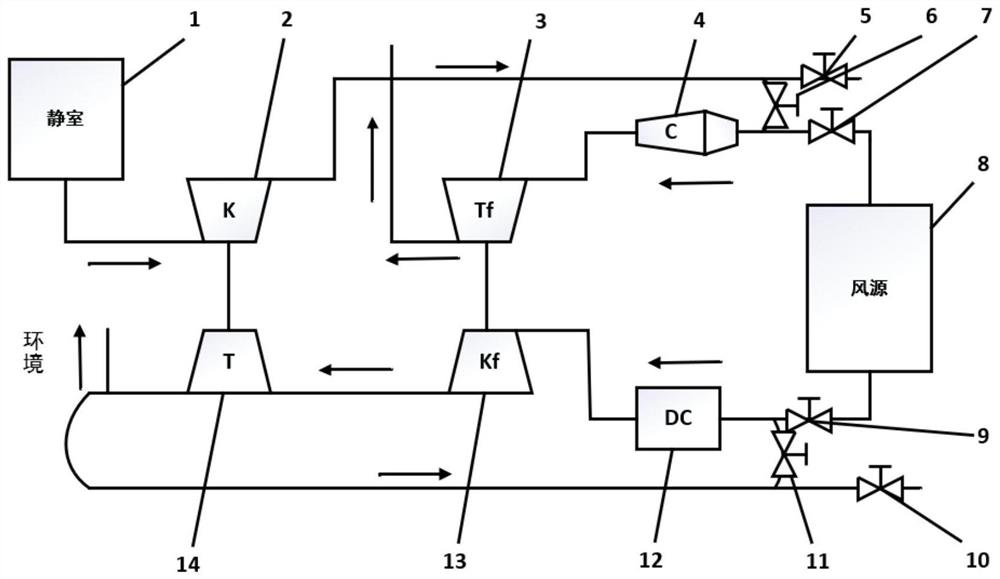

[0022] combine figure 1 , the invention is composed of an open air compressor performance test circuit and a closed turbine performance test circuit. It includes static chamber 1, compressor 2, gas turbine 3, combustion chamber 4, intake valve, exhaust valve, wind source 8, electric heater 12, centrifugal high-temperature gas compressor 13, and turbine 14. The intake valve includes intake valve Ⅰ6, intake valve Ⅱ7, intake valve Ⅲ9 and intake valve Ⅳ11, which are respectively connected behind the compressor 2, after the upper port of the air source 8, after the lower port of the air source 8 and after the turbine 14. The exhaust valves include exhaust valve I5 and exhaust valve II10, which are the exhaust valves of the open compressor circuit and the closed turbine circuit respectively.

[0023] The open compressor performance test circuit includes static chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com