Air inlet simulation system, air inlet simulation method and empty model pressure loss simulation method

A technology for simulating systems and models, applied in the field of wind tunnel testing, which can solve problems such as poor flow stability, large pressure loss range, and insufficient suction capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

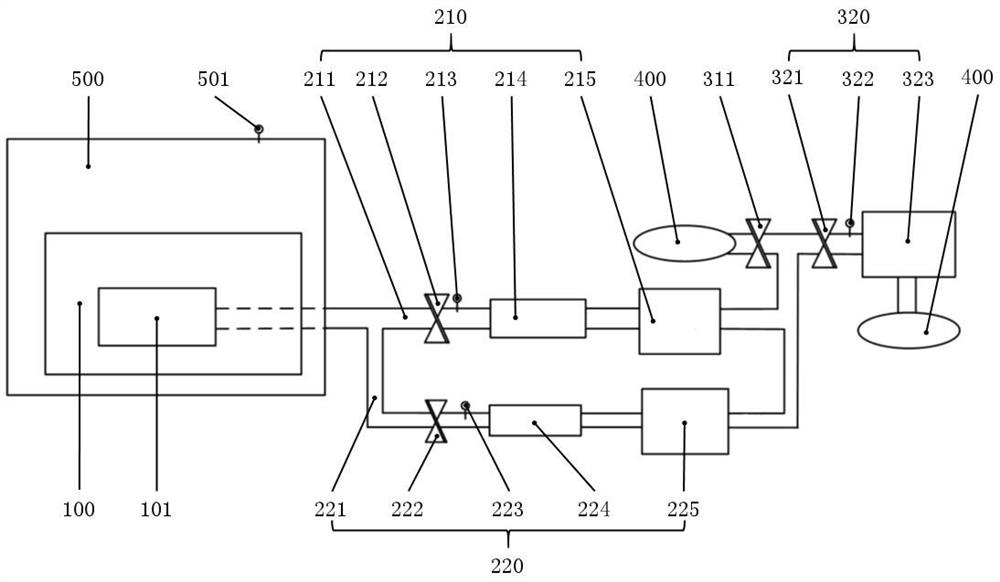

[0046] Such as figure 1 As shown, Embodiment 1 of the present invention provides an air intake simulation system, including: a test model 100, a large-flow air extraction mechanism 210, a small-flow air extraction mechanism 220, and an air outlet mechanism (not shown in the figure due to the viewing angle) ):

[0047] The inlet end of the small-flow air extraction mechanism 220, the air inlet end of the large-flow air extraction mechanism 210, and the air outlet end of the test model 100 are connected to each other;

[0048] The large flow suction mechanism 210 includes a large centrifugal fan 215, and the large centrifugal fan 215 is located on the large flow suction mechanism 210 and is close to the gas outlet side, and the small flow suction mechanism 220 includes a small centrifugal fan 225. The small centrifugal fan 225 is located on the side of the small flow suction mechanism 220 close to the air outlet, and the flow rate of the large centrifugal fan 215 is greater tha...

Embodiment 2

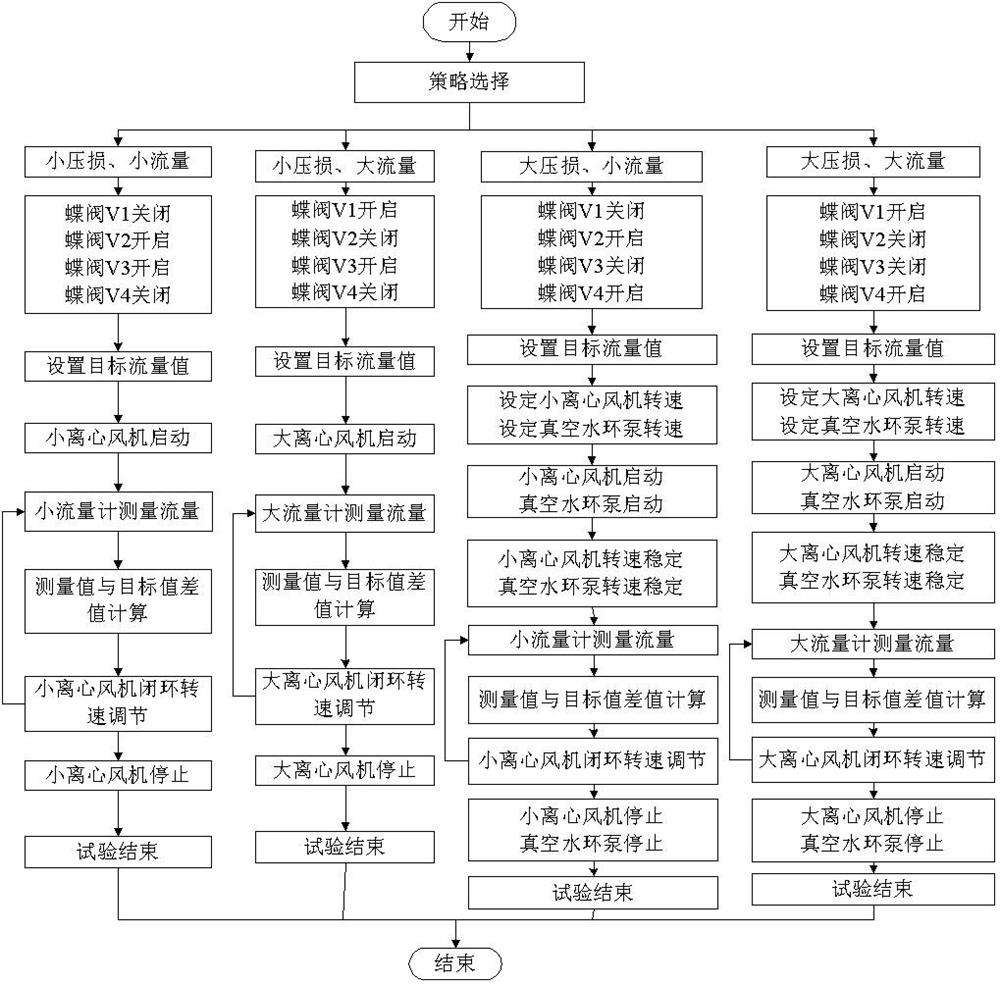

[0067] Such as figure 2 As shown, Embodiment 2 of the present invention provides an air intake simulation method of an air intake simulation system, which is characterized in that it includes the following steps:

[0068] Obtaining test requirements, the test requirements include pressure loss requirements and flow requirements, the pressure loss requirements include large pressure loss or small pressure loss, and the flow requirements include large flow or small flow;

[0069] When the pressure loss demand is a large pressure loss, then close the third on-off valve 311, open the fourth on-off valve 321 and the vacuum pump 323; when the pressure loss demand is a small pressure loss, then open the The third on-off valve 311 closes the fourth on-off valve 321;

[0070] When the flow demand is a small flow, then open the large flow pumping mechanism 210, close the small flow pumping mechanism 220; when the flow demand is small flow, then open the small flow pumping mechanism 22...

Embodiment 3

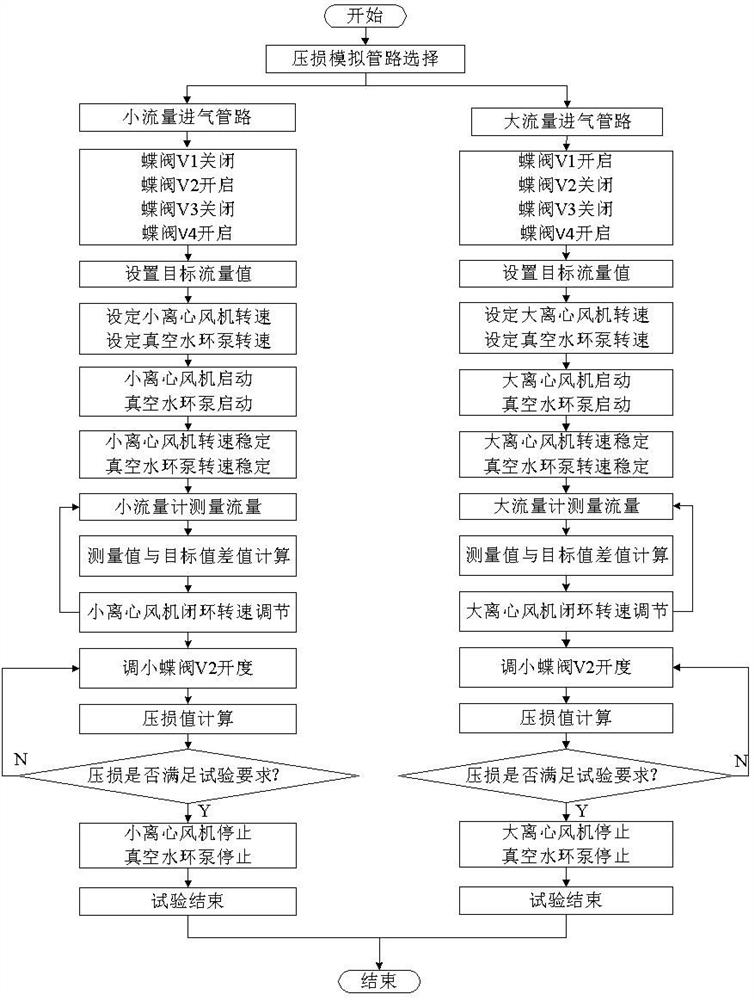

[0080] Such as image 3 As shown, Embodiment 3 of the present invention provides a schematic diagram of the air intake simulation system in Embodiment 1 in the air model pressure loss simulation. A method for simulating air model pressure loss of an air intake simulation system, comprising the steps of:

[0081] When performing large-flow empty model pressure loss simulation, open the large-flow pumping mechanism 210 and the fourth switching valve 321, and adjust the opening of the large-flow pumping mechanism 210 to obtain the first pressure at different openings Pressure value of sensor 501 P 1 and the pressure value of the second pressure sensor 213 P 2 , to calculate the pressure loss value of the large flow rate P s 2 for: P s 2 =P 1 -P 3 ; When carrying out the small-flow empty model pressure loss simulation, open the small-flow pumping mechanism 220 and the fourth switching valve 321, and adjust the opening of the small-flow pumping mechanism 220 to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com