Multifunctional VHP sterilizer

A sterilizer and multi-functional technology, applied in household heating, space heating and ventilation details, heating methods, etc., can solve problems such as high use conditions, long disinfection cycle, and poor HEPA penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

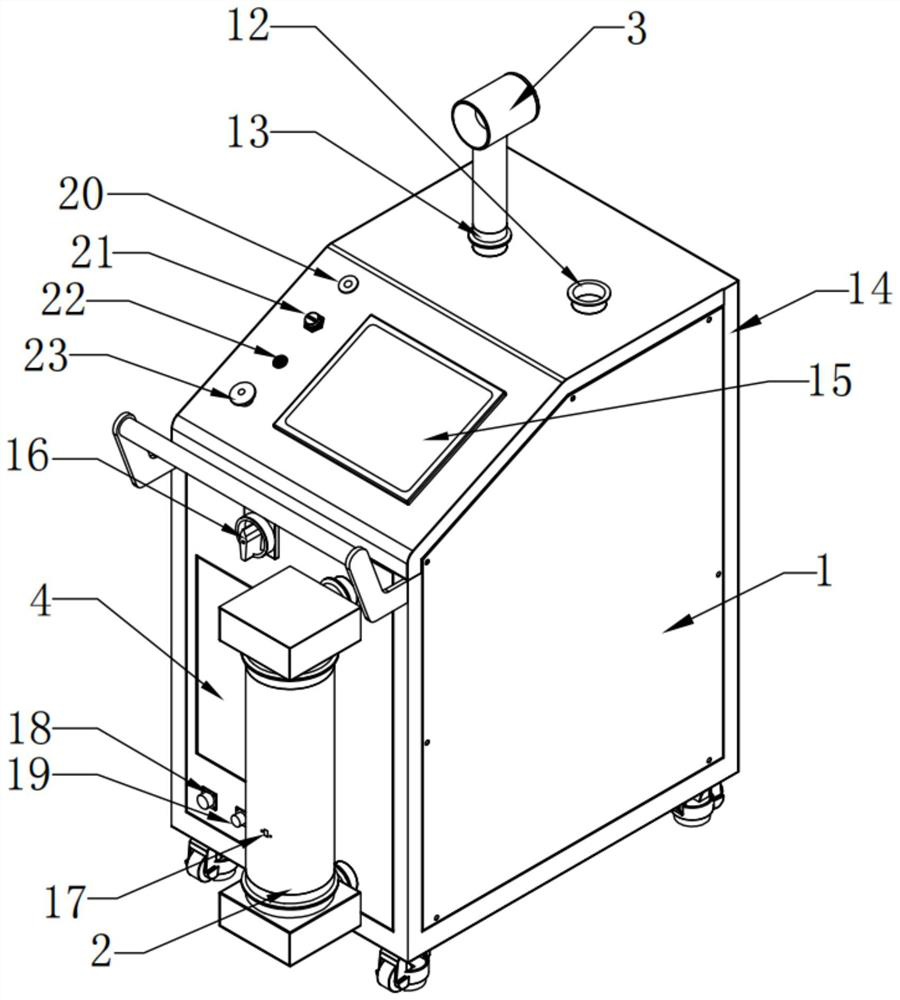

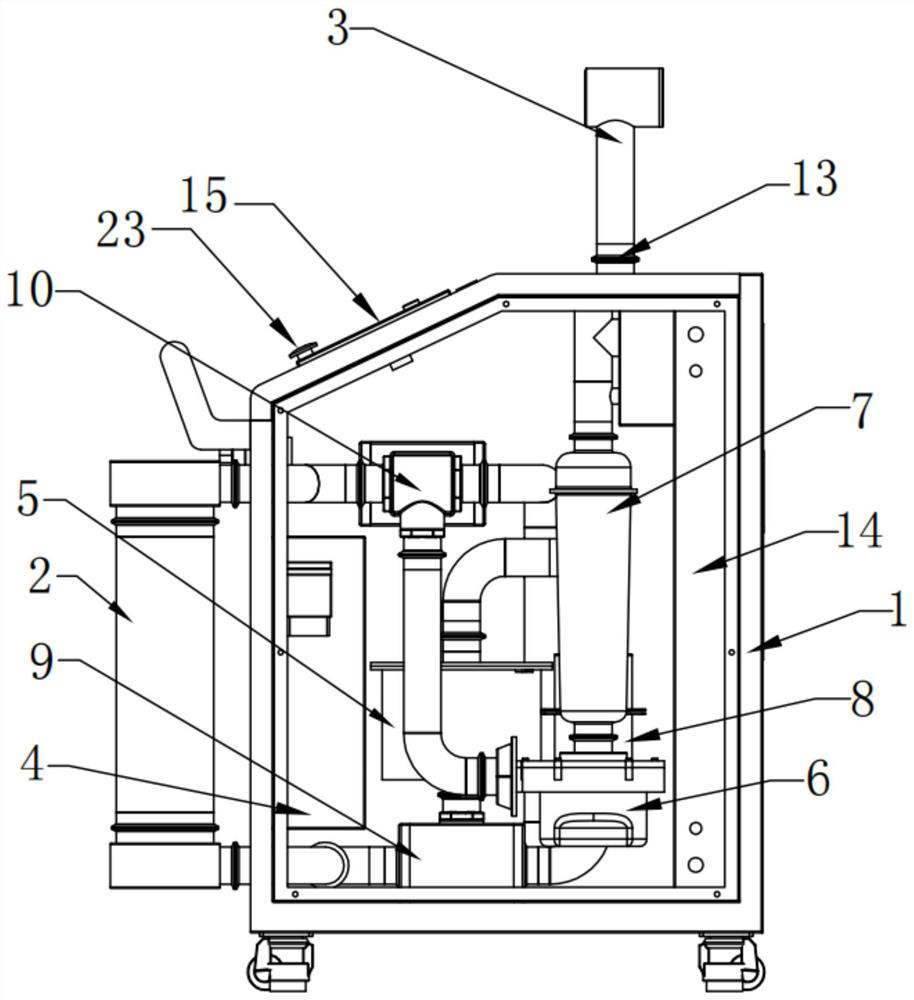

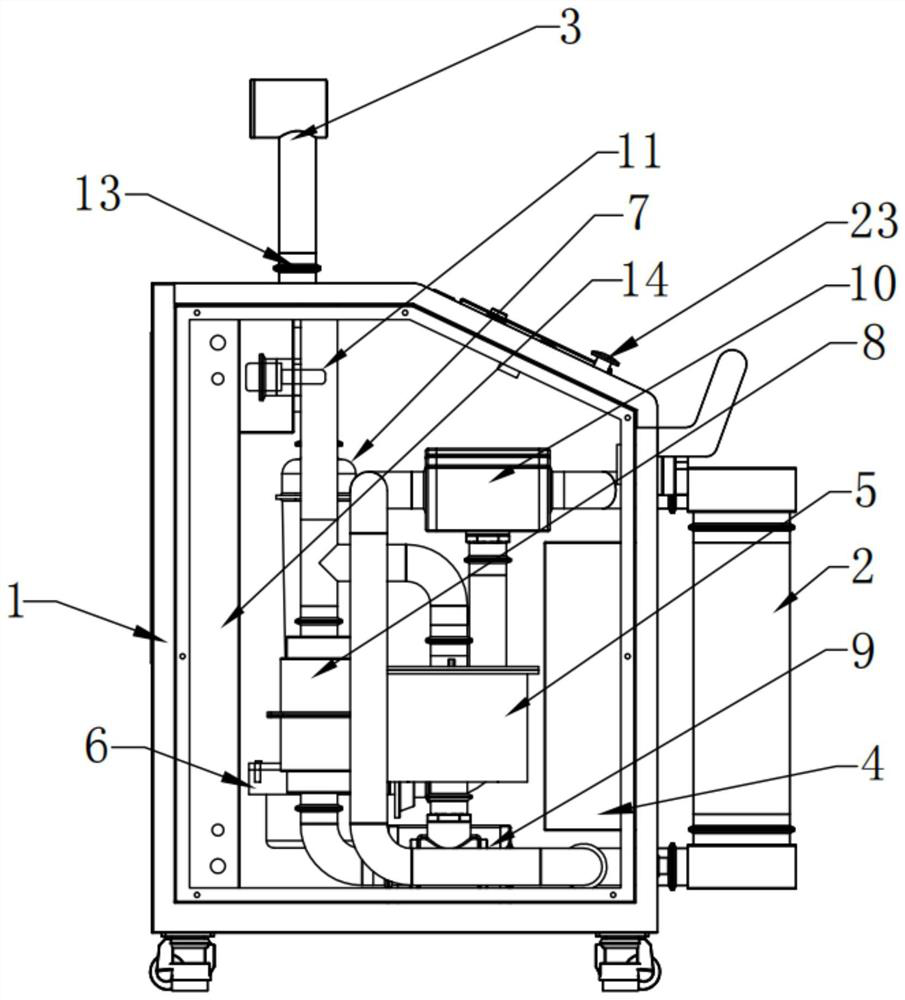

[0029] Please refer to Figure 1-4 . The multifunctional VHP sterilizer includes: a body 1, an external drying system 2 and a hydrogen peroxide solution cabinet 4 are arranged on one side of the body 1, a Venturi nozzle 3 is arranged on the top of the body 1, and the body 1 A VHP flash evaporator 5, a speed-regulating blower 6, a filter 7 and a degrader 8 are arranged inside, and the VHP flash evaporator 5, a speed-regulating blower 6, a filter 7 and a degrader 8 are all connected with the external drying system 2 and The hydrogen peroxide solution cabinet 4 is communicated through a parallel pipeline, the degrader 8 is communicated with the Venturi nozzle 3, and the parallel pipeline is provided with a first electric ball valve 9, a second electric ball valve 10 and a three-way valve. A concentration probe 11, the first electric ball valve 9 is located below the VHP flash evaporator 5, the second electric ball valve 10 is located above the VHP flash evaporator 5, and the thr...

no. 2 example

[0044] Based on the multifunctional VHP sterilizer provided in the first embodiment of the present application, the second embodiment of the present application proposes another multifunctional VHP sterilizer. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0045] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0046] Please refer to Figure 5-7 , the multifunctional VHP sterilizer further includes a screen protection mechanism, the screen protection mechanism is arranged on the body 1 , and the screen protection mechanism corresponds to the main operation screen 15 .

[0047] The screen protection mechanism includes a mounting piece 24, a supporting piece 25, a flip cover 26, an inner sealing plate 27, a fixing mechanism and an emergency t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com