Gas turbine guide vane

A technology of guide vanes and gas turbines, applied in climate sustainability, sustainable transportation, machines/engines, etc., can solve problems such as poor cooling effect and difficult casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

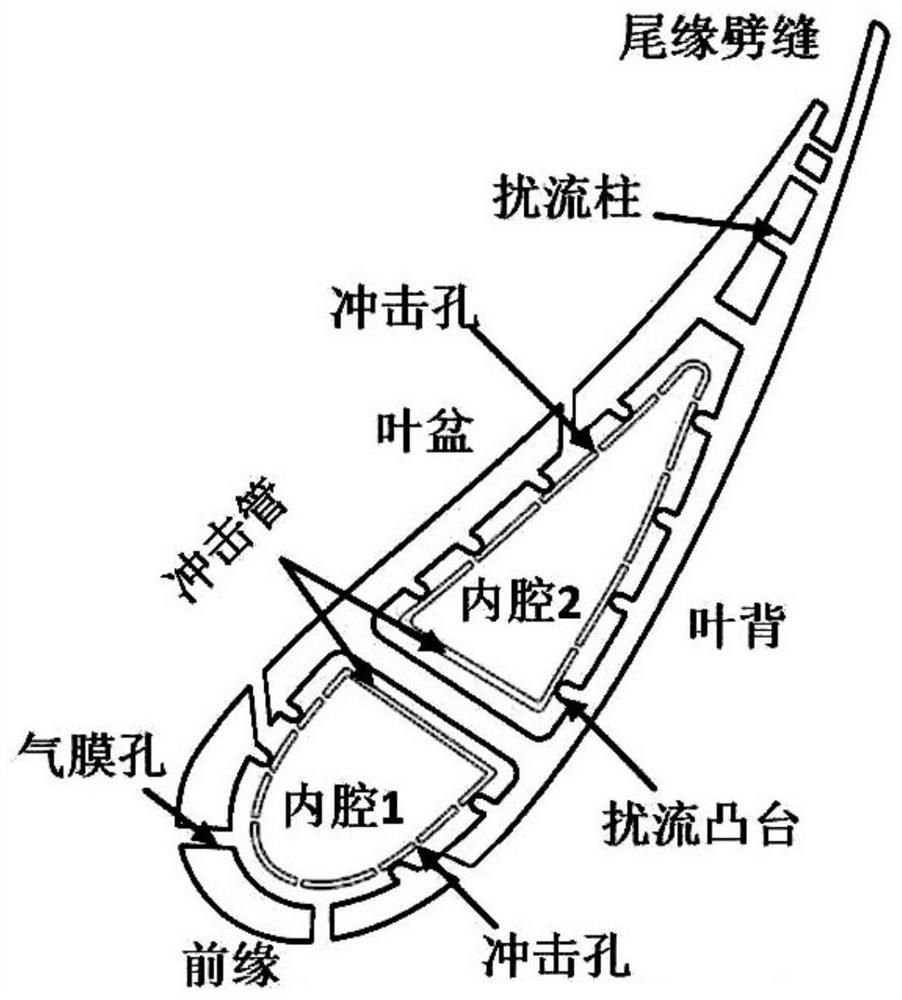

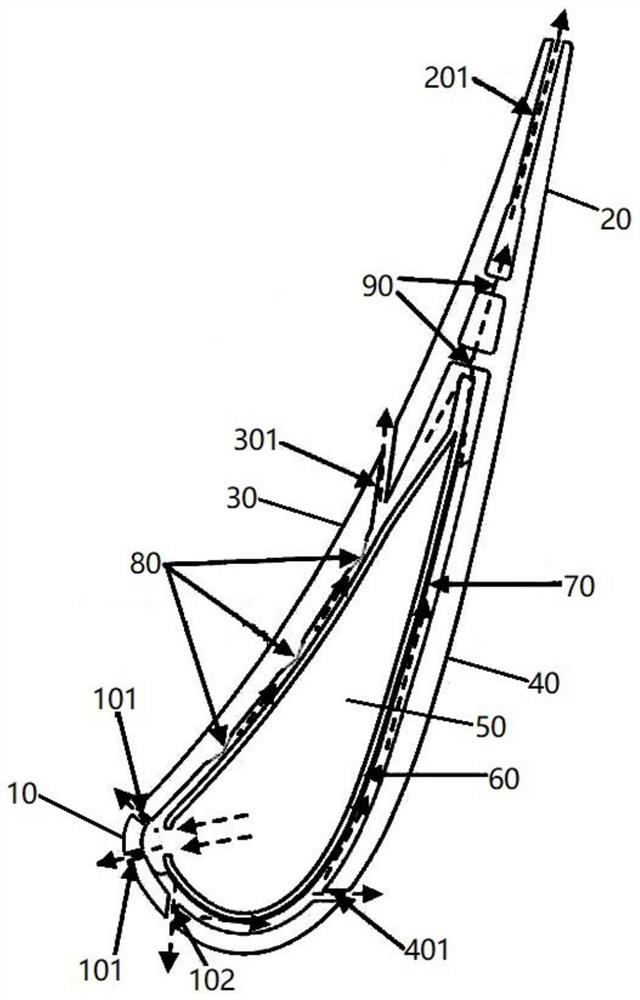

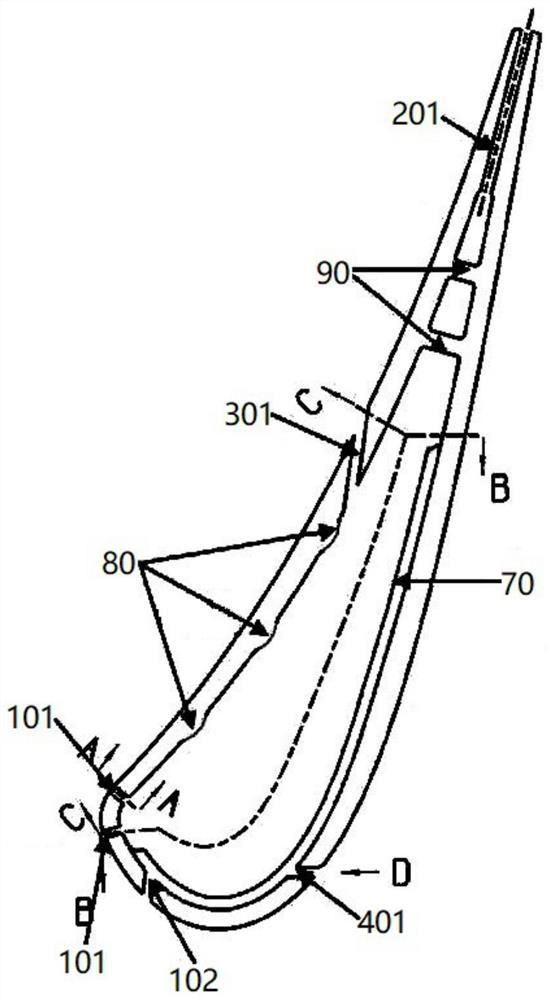

[0036] refer to figure 2, the preferred embodiment of the present invention provides a gas turbine guide vane, comprising a blade airfoil, the blade airfoil has an airfoil leading edge 10, a trailing edge 20, a blade pot 30 and a blade back 40, and a single inner cavity is also provided in the blade airfoil 50. An impact tube 60 communicating with the cold air circuit is installed in the inner cavity 50. The front edge of the impact tube 60 is provided with a jet slit 601 that runs through the front edge. The jet slit 601 is used for the cold air flow in the inner cavity 50. Jet impingement cooling is performed on the inner wall surface of the airfoil leading edge 10 after piercing. The outer wall surface of the airfoil leading edge 10 is also provided with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com