Pre-buried flue mounting device and using method thereof

A technology for installing devices and flues, which can be used in vertical pipes, building components, buildings, etc., and can solve problems such as irregular unloading practices and inconvenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

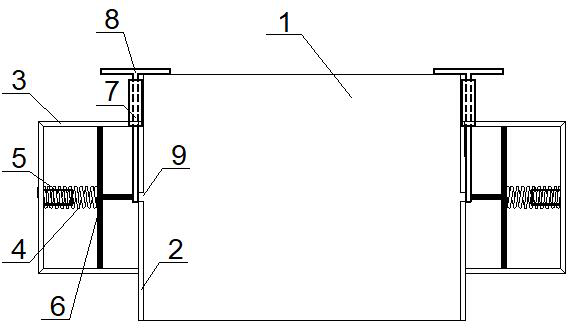

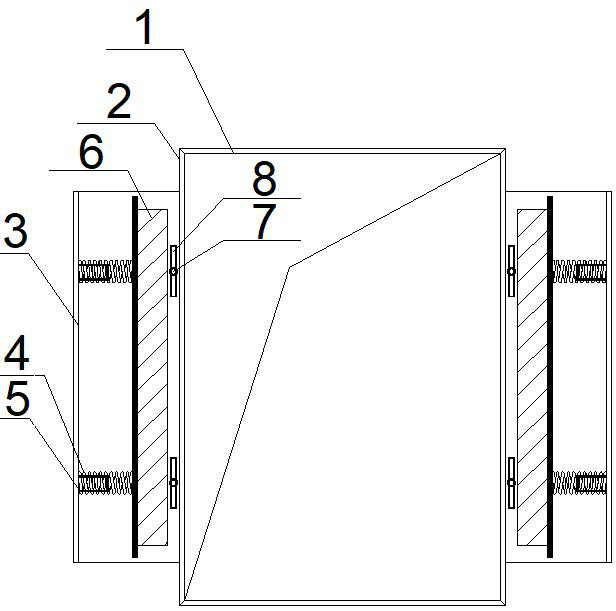

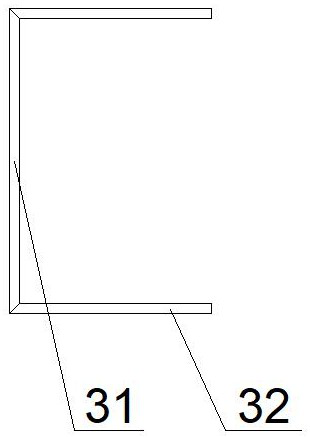

[0027] like Figure 1-Figure 5 As shown, a pre-buried flue installation device includes a pair of connecting baffles 1 and a pair of stressed baffles 2, the connecting baffles 1 and stressed baffles 2 form a vertical rectangular channel 10, each A C-shaped protective tube 3 is connected to the outer wall of a stressed baffle 2, and the C-shaped protective tube 3 is composed of a web 31 and a wing plate 32 at both ends of the web 31. The opening end of the C-shaped protective tube 3 faces the stressed baffle. 2. There is a telescopic plate 6 inside the C-shaped protective tube 3. The telescopic plate 6 is composed of an inserting plate 61 and a limiting plate 62 vertically connected. The inserting plate 61 is parallel to the cross section of the rectangular channel 10, and the limiting plate 62 is parallel to the force The baffle plate 2, the force baffle plate 2 is provided with a slot 9 for the insertion plate 61 to pass through, and a pressure spring 4 is provided between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com