Corrosion-resistant PI thrust pad and preparation method thereof

A thrust pad and corrosion-resistant technology, which is applied in the field of thrust pads, can solve the problems of low transmission system efficiency and large thrust pad effect, and achieve the effects of reducing hydrophilicity, improving corrosion resistance, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

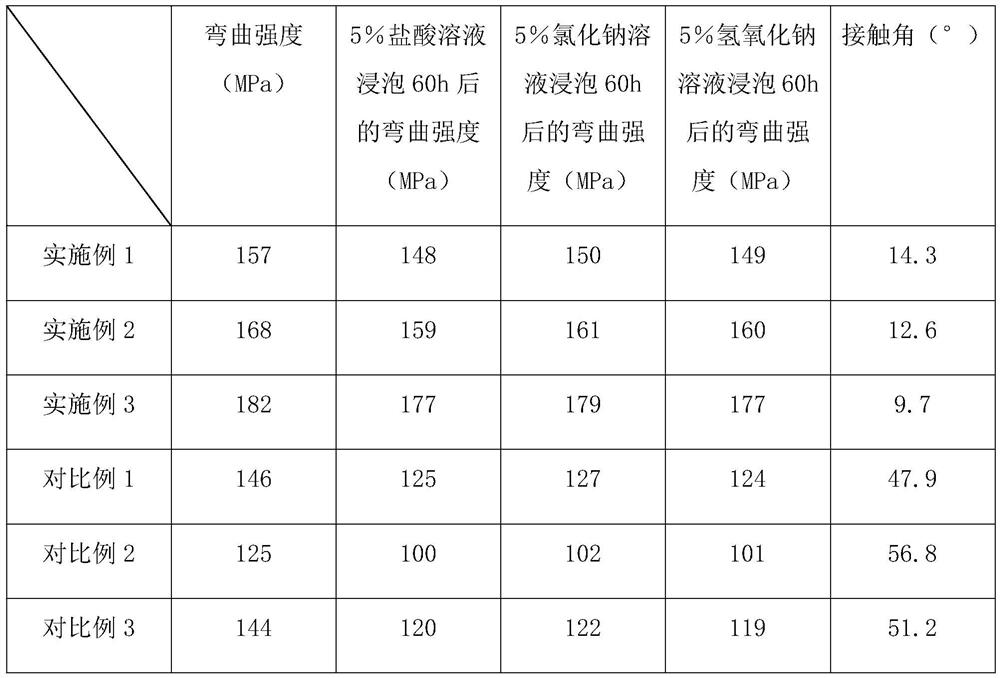

Examples

Embodiment 1

[0047] A method for preparing a corrosion-resistant PI thrust pad, comprising the following steps:

[0048] S1: Reacting graphene oxide and chitosan to prepare a carbon matrix composite;

[0049] S2: reacting toluene diisocyanate, pyromellitic anhydride, terbium chloride and the carbon matrix compound to prepare a polyimide compound;

[0050] S3: Melt extrusion and injection molding of the polyimide compound to obtain a thrust pad;

[0051] S4: Treat the surface of the thrust pad with perfluorobutane to prepare a corrosion-resistant PI thrust pad.

[0052] Among them, S1:

[0053] Mix graphene oxide with deionized water, stir mechanically for 20 minutes, disperse ultrasonically for 5 minutes, add 1-ethyl-carbodiimide hydrochloride and N-hydroxysuccinimide, heat in a water bath to 40°C, and stir mechanically 40 minutes, ultrasonic dispersion for 80 minutes, adding acetic acid and chitosan, stirring mechanically for 1 hour, refluxing for 3 hours, filtering, washing with deioniz...

Embodiment 2

[0062] A method for preparing a corrosion-resistant PI thrust pad, comprising the following steps:

[0063] S1: Reacting graphene oxide and chitosan to prepare a carbon matrix composite;

[0064] S2: reacting toluene diisocyanate, pyromellitic anhydride, terbium chloride and the carbon matrix compound to prepare a polyimide compound;

[0065] S3: Melt extrusion and injection molding of the polyimide compound to obtain a thrust pad;

[0066] S4: Treat the surface of the thrust pad with perfluorobutane to prepare a corrosion-resistant PI thrust pad.

[0067] Among them, S1:

[0068] Mix graphene oxide with deionized water, stir mechanically for 20 minutes, disperse ultrasonically for 5 minutes, add 1-ethyl-carbodiimide hydrochloride and N-hydroxysuccinimide, heat in a water bath to 40°C, and stir mechanically 40 minutes, ultrasonic dispersion for 80 minutes, adding acetic acid and chitosan, stirring mechanically for 1 hour, refluxing for 3 hours, filtering, washing with deion...

Embodiment 3

[0077] A method for preparing a corrosion-resistant PI thrust pad, comprising the following steps:

[0078] S1: Reacting graphene oxide and chitosan to prepare a carbon matrix composite;

[0079] S2: reacting toluene diisocyanate, pyromellitic anhydride, terbium chloride and the carbon matrix compound to prepare a polyimide compound;

[0080] S3: Melt extrusion and injection molding of the polyimide compound to obtain a thrust pad;

[0081] S4: Treat the surface of the thrust pad with perfluorobutane to prepare a corrosion-resistant PI thrust pad.

[0082] Among them, S1:

[0083] Mix graphene oxide with deionized water, stir mechanically for 20 minutes, disperse ultrasonically for 5 minutes, add 1-ethyl-carbodiimide hydrochloride and N-hydroxysuccinimide, heat in a water bath to 40°C, and stir mechanically 40 minutes, ultrasonic dispersion for 80 minutes, adding acetic acid and chitosan, stirring mechanically for 1 hour, refluxing for 3 hours, filtering, washing with deion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com