Small casting clamping and carrying device

A technology for handling devices and casting clamps, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., and can solve problems such as high safety, low handling efficiency, and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

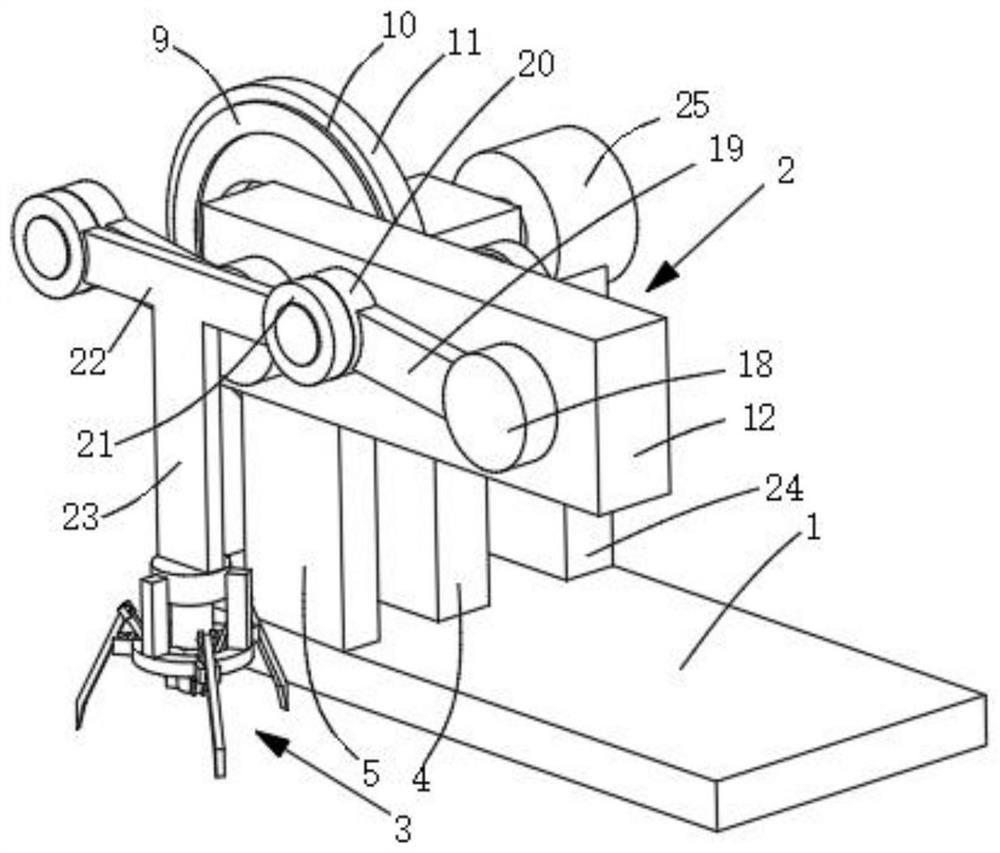

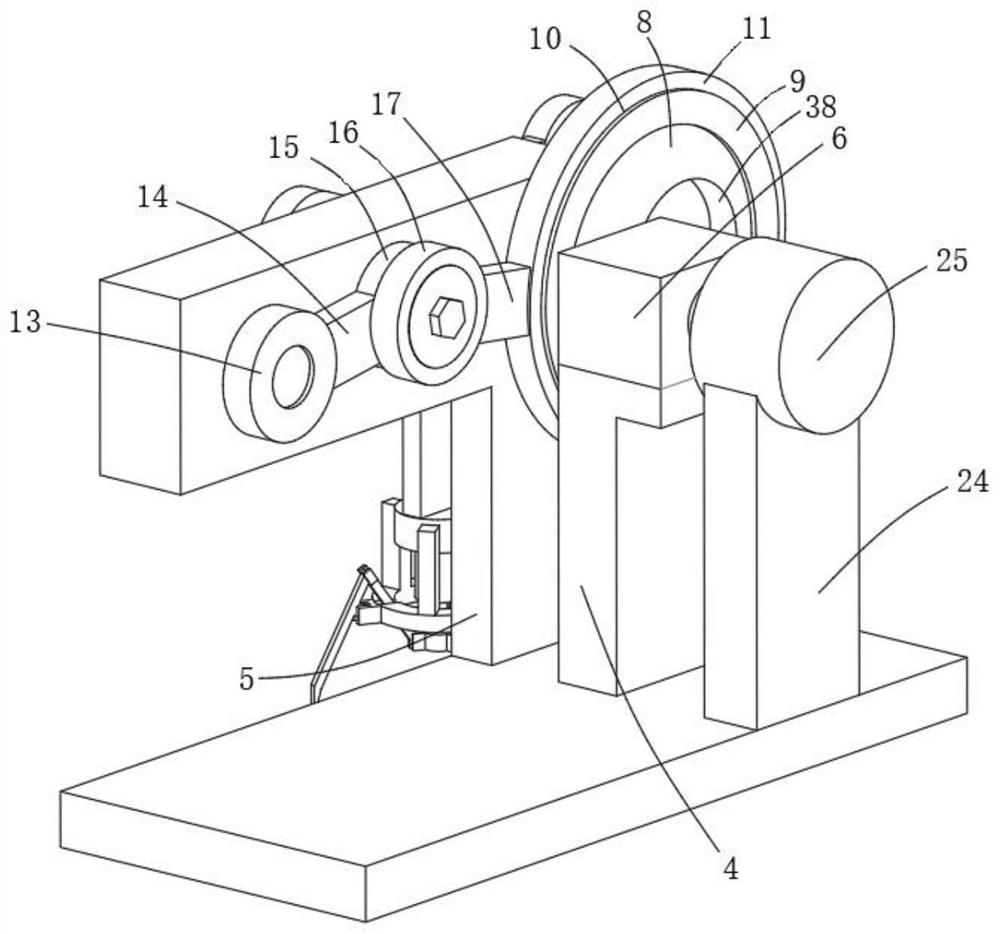

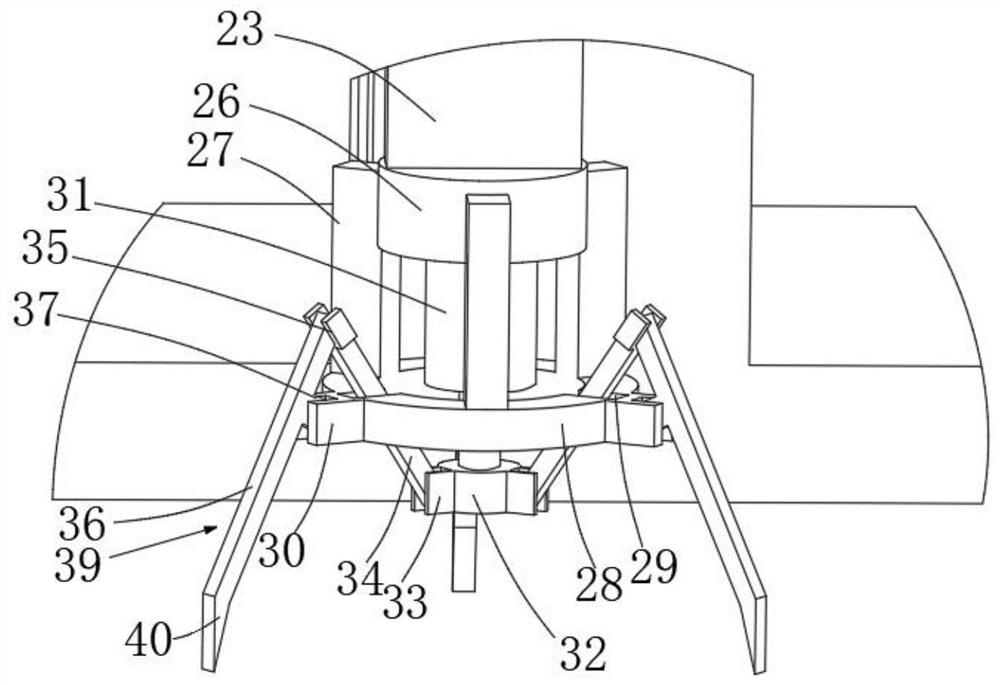

[0022] Embodiment: small casting clamping and carrying device, as attached figure 1 And attached figure 2 As shown, it includes a bottom plate 1, and the bottom plate 1 is provided with a transport mechanism 2, and the transport mechanism 2 is provided with a clamping mechanism 3; the transport mechanism 2 includes a first support plate 4 and a second support plate arranged on the base 1 plate 5, the top of the first support plate 4 is provided with a first mounting block 6, as attached Figure 4As shown, the first mounting block 6 is provided with a transmission shaft 7, and the end of the transmission shaft 7 is provided with a circular plate 8 between the first support plate 4 and the second support plate 5, and the connection between the transmission shaft 7 and the circular plate 8 The joint is far away from the center of the circular plate 8, the outer edge of the circular plate 8 is provided with an annular frame 9, the outer side of the annular frame 9 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com