Electric steering structure of counterbalance forklift truck

A heavy-duty forklift, electric steering technology, applied in electric steering mechanism, steering mechanism, steering gear, etc., can solve the problems of difficult forklift layout, large turning radius, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below through specific embodiments.

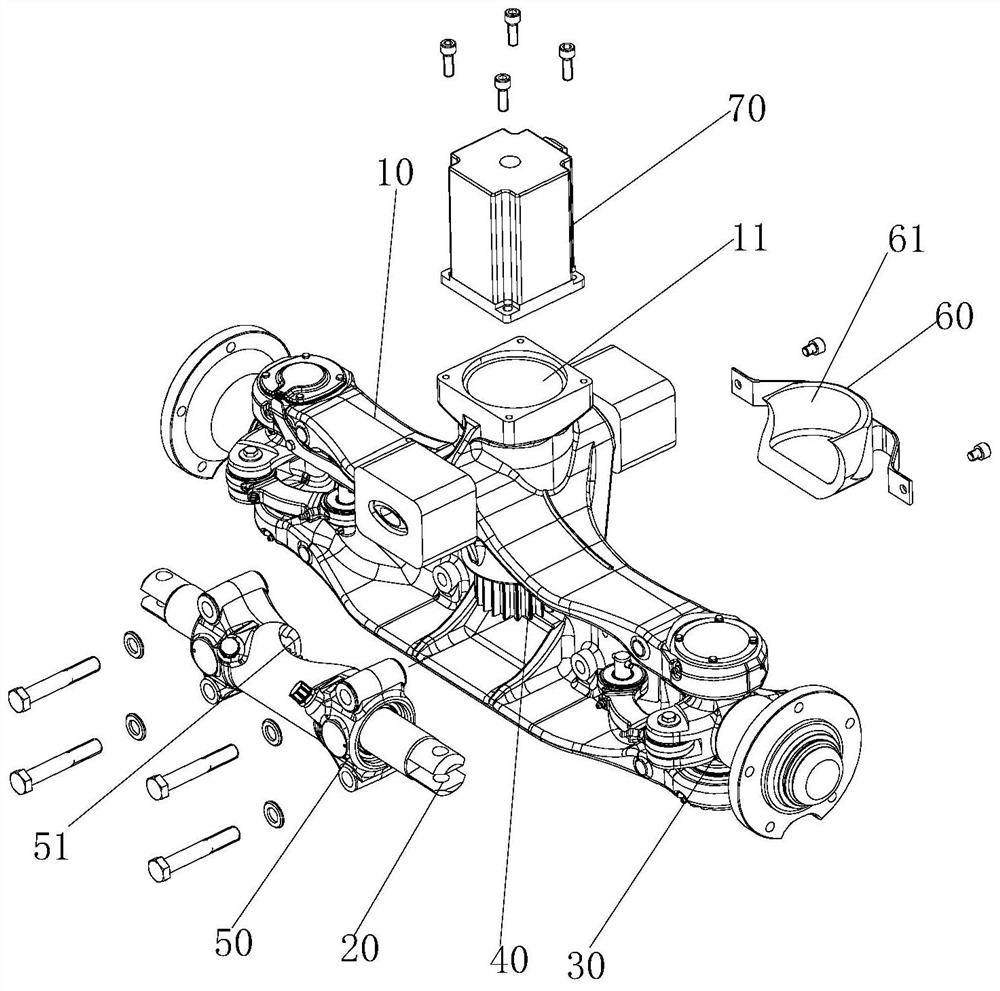

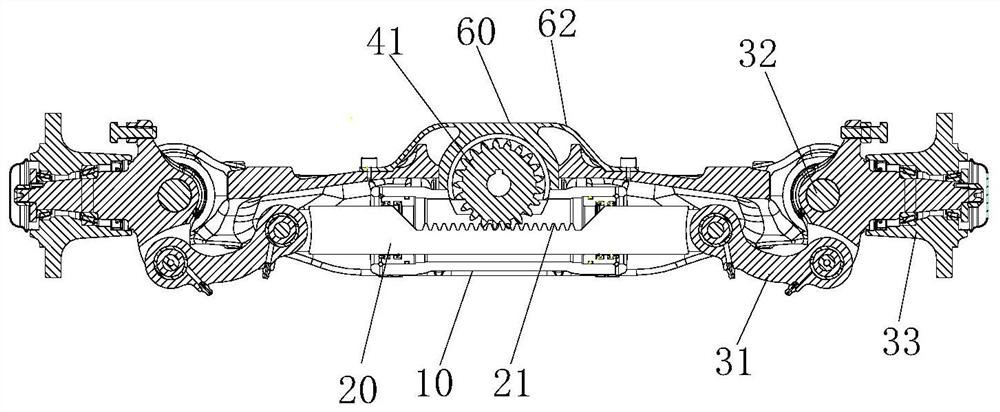

[0032] refer to Figure 1 to Figure 8 , an electric steering structure of a counterbalanced forklift, including a steering bridge, a steering motor 70, a reduction mechanism 40 and other structures. The steering bridge body is used as an actuator for steering action, and it is provided with a housing 10, a tie rod 20, a connecting rod 31, a steering knuckle 30, and the like. The main body of the shell 10 is made by one-time casting method. The tie rod 20 is located in the casing 10 , and the steering knuckle 30 is connected with the tie rod 20 .

[0033] Specifically, it includes two steering knuckles 30 which are respectively connected to the two ends of the tie rod 20 , and the steering knuckle 30 and the tie rod 20 are rotatably connected through a connecting rod 31 . The steering knuckle 30 adopts a conventional steering connection structure, which is driven by a slider rocker, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com