Method for manufacturing part layer-upon-layer using additive manufacturing technology and pressing system

A technology of additive manufacturing and layer-by-layer manufacturing, which is applied in the directions of processing and manufacturing, manufacturing tools, and additive manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] Those skilled in the art should realize that the aspects described herein can be embodied as a method of manufacturing part 1 , a pressing system, or an additive manufacturing tool.

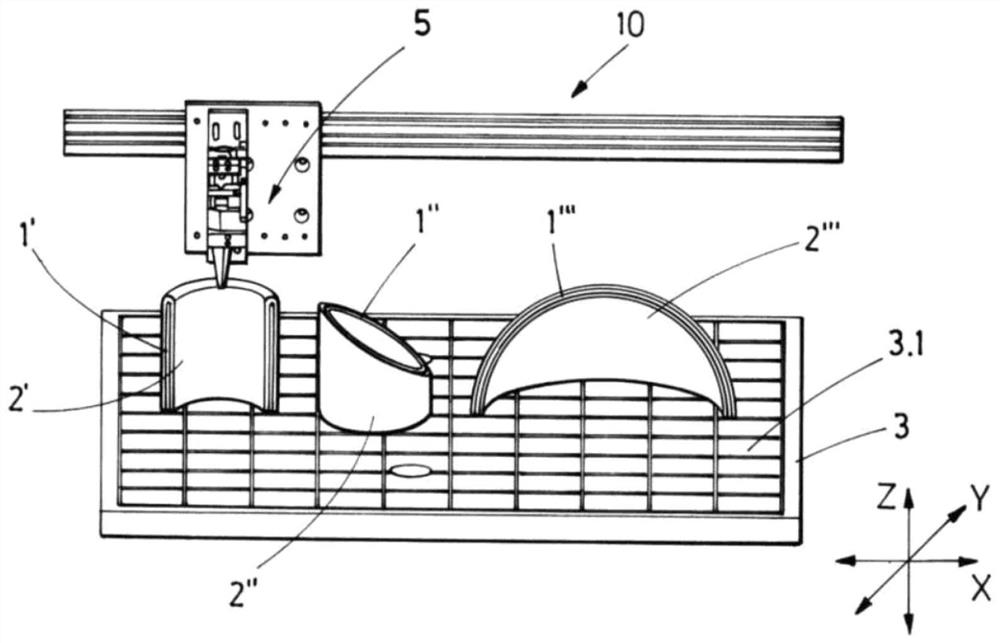

[0129] The invention defines a method for producing a part 1 layer by layer using additive manufacturing techniques. Basically, the method consists of the following steps:

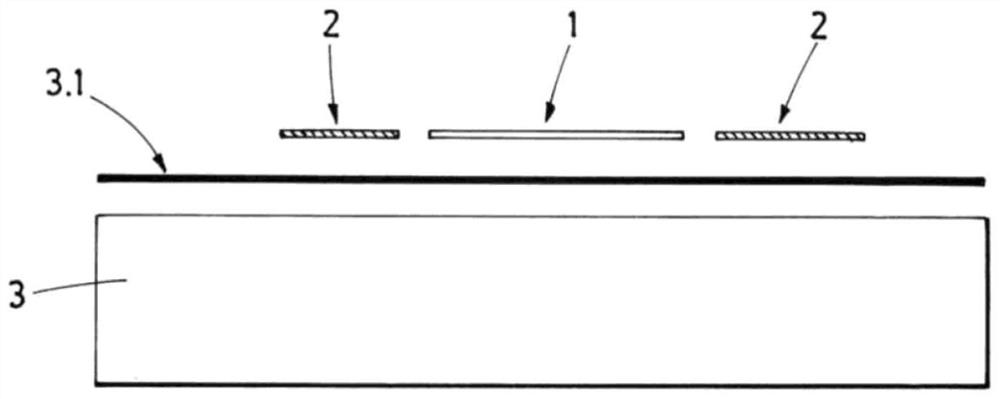

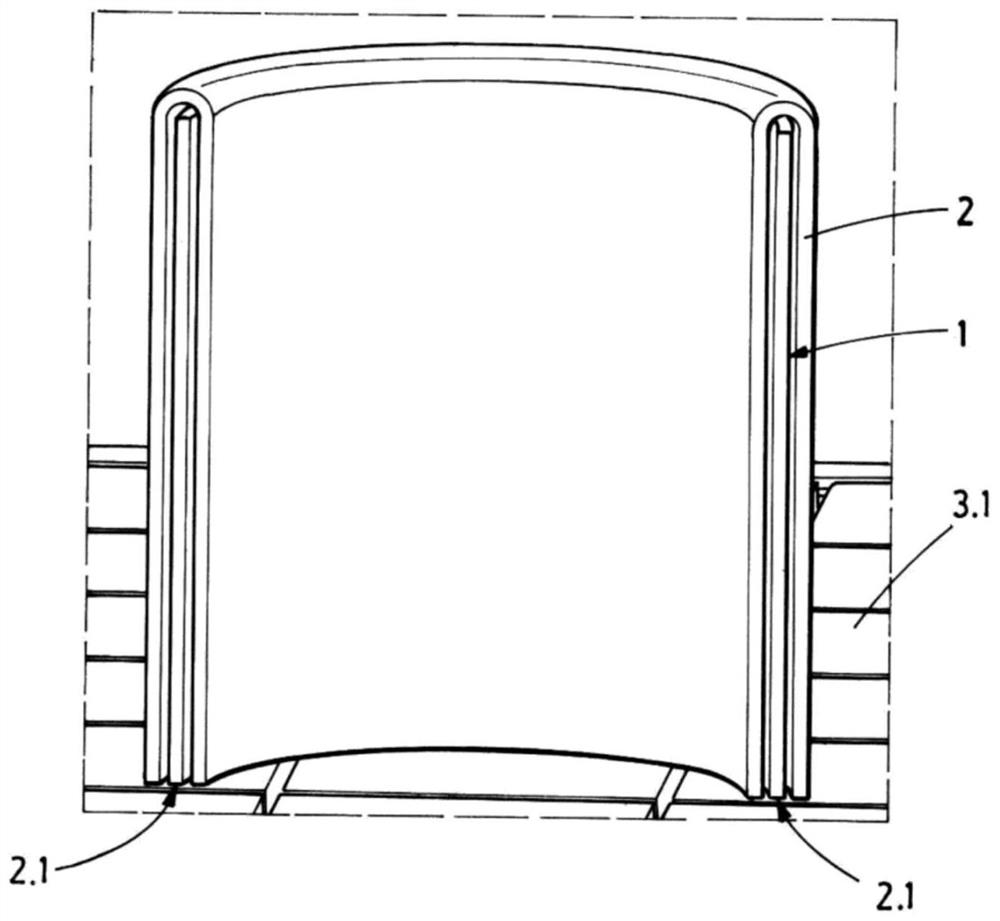

[0130] - printing the part 1 together with the elastomeric casing 2 formed thereon, leaving a material-free gap between the part and the elastomeric casing, the elastomeric casing comprising at least one opening 2.1;

[0131] - Heating the integral part of the printed part 1 and the elastomeric casing 2 or maintaining the operating printing temperature;

[0132] - applying a vacuum through at least one opening 2.1 of the elastomeric sheath 2, causing the elastomeric sheath to deflate, thereby applying pressure to the printed part 1; and

[0133] - Keeping the printed part 1 under vacuum and heat during a predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com